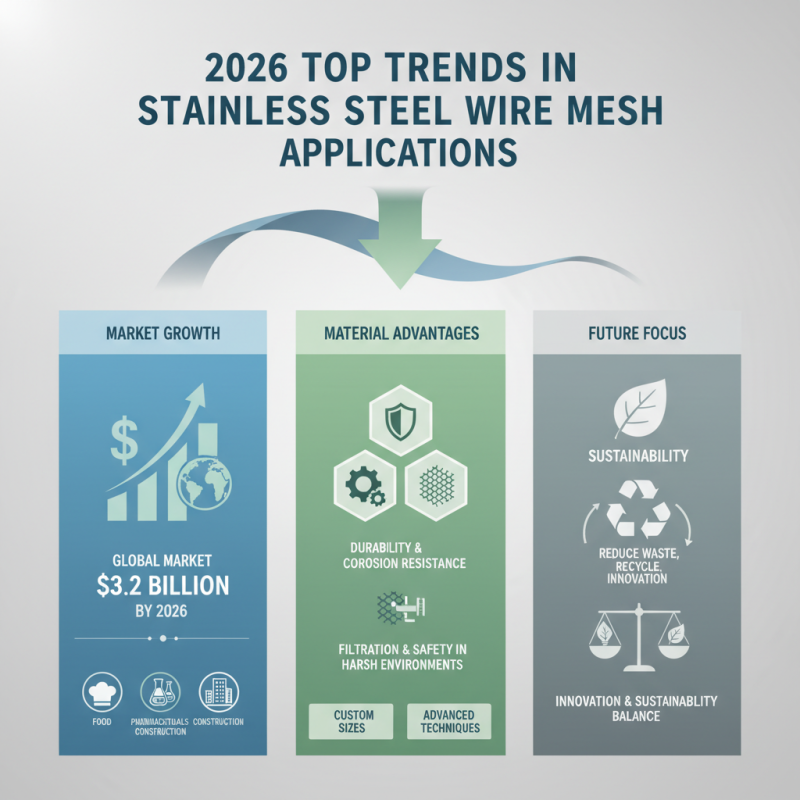

2026 Top Trends in Stainless Steel Wire Mesh Applications?

In recent years, the application of stainless steel wire mesh has seen remarkable growth across diverse industries. According to a report by MarketsandMarkets, the global stainless steel wire mesh market is projected to reach $3.2 billion by 2026, driven by rising demand in sectors such as food processing, pharmaceuticals, and construction. Stainless steel wire mesh offers durability, corrosion resistance, and versatility, making it an ideal choice for many applications.

Industry expert Dr. Emily Carter highlights the significance of this material, noting, "Stainless steel wire mesh is revolutionizing how we approach filtration and safety in harsh environments." As companies pursue innovative solutions, trends in custom sizes and advanced weaving techniques have emerged. The versatility of stainless steel wire mesh allows for specialized applications, from architectural facades to intricate industrial filters.

However, challenges remain. Sustainability is a growing concern, and the industry must adapt to shifting environmental regulations. Innovation should focus on recycling and reducing waste. As we look toward 2026, the potential of stainless steel wire mesh is vast, yet it requires reflection on its production processes. A balance between innovation and sustainability will be crucial for future growth.

Emerging Applications in Construction and Architecture Using Stainless Steel Wire Mesh

In recent years, stainless steel wire mesh has found innovative applications in construction and architecture. Its strength and durability make it an ideal choice for various projects. According to a report by the International Wire and Cable Products industry, the use of stainless steel wire mesh in construction is predicted to grow by over 15% annually through 2026. This showcases its rising importance in modern architecture.

Stainless steel wire mesh plays a crucial role in facades and safety barriers. It offers both aesthetic appeal and structural integrity. For instance, many architects now incorporate mesh in their designs, creating visually striking structures while ensuring safety. These applications are not without challenges. Designers must carefully consider weight, maintenance, and alignment. Minor errors in installation can lead to substantial consequences.

Tips: When integrating stainless steel wire mesh in your project, assess the environment. Corrosion resistance is paramount. Also, seek feedback from peers. Their insights can help refine your design and approach. Emphasizing collaboration can also mitigate potential pitfalls in the execution phase of your projects.

2026 Top Trends in Stainless Steel Wire Mesh Applications

| Application Area | Key Features | Benefits | Projected Growth % (2026) |

|---|---|---|---|

| Architectural Facades | Lightweight, Corrosion Resistant | Enhanced Aesthetics, Durability | 15% |

| Safety Screens | High Strength, Versatile | Improved Safety, Functionality | 10% |

| Infill Panels | Customizable Designs | Architectural Freedom | 18% |

| Environmental Filters | High Filtration Efficiency | Pollution Control | 12% |

| Gardening and Landscaping | Durable, Aesthetic | Sustainable Landscaping Solutions | 20% |

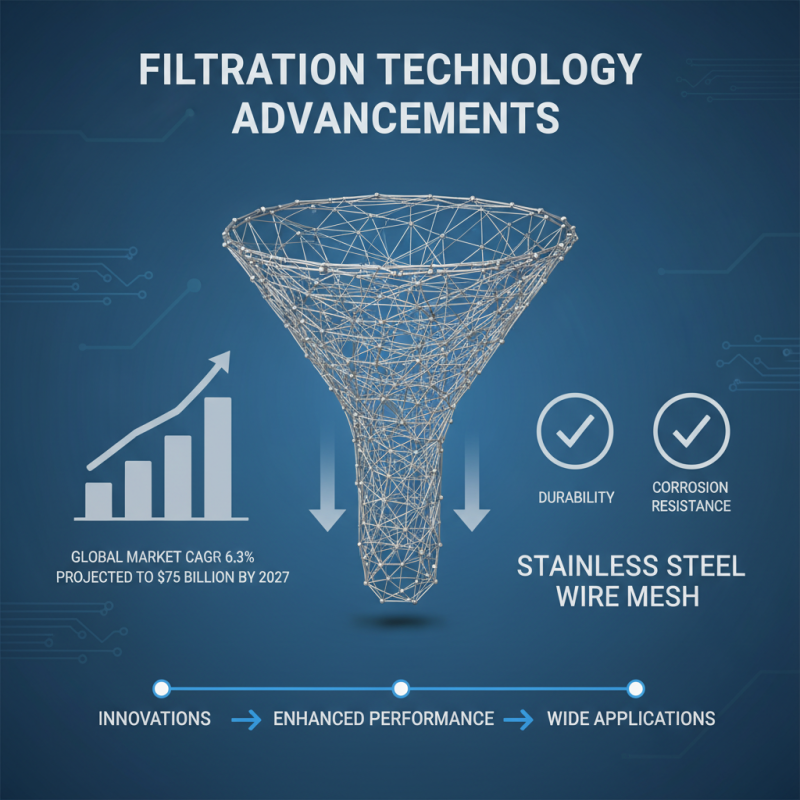

Advancements in Filtration Technologies Leveraging Stainless Steel Wire Mesh

The advancements in filtration technologies with stainless steel wire mesh are remarkable. In recent years, the global filtration market has expanded at a compound annual growth rate (CAGR) of 6.3%, projected to reach $75 billion by 2027. This growth is attributed to innovations in materials and designs that enhance filtration performance. Stainless steel wire mesh excels in durability and corrosion resistance, making it ideal for various filtration applications.

Industries such as food processing and pharmaceuticals heavily rely on stainless steel wire mesh for their filtration needs. Mesh sizes are versatile, ranging from 5 microns to 1000 microns, ensuring that particles are trapped effectively. Yet, challenges remain. Companies must adapt to strict regulations and higher consumer expectations. Traditional methods may not suffice anymore. Innovative approaches will be necessary for compliance and efficiency improvements.

Another area of focus is the environmental impact. Filtration technology must balance effectiveness and sustainability. The use of stainless steel mesh can reduce waste compared to disposable alternatives. However, manufacturers need to continue refining their processes. Continuous research will be crucial to harness the full potential of stainless steel wire mesh in filtration technologies. The future appears promising, but obstacles must be addressed for maximum effectiveness.

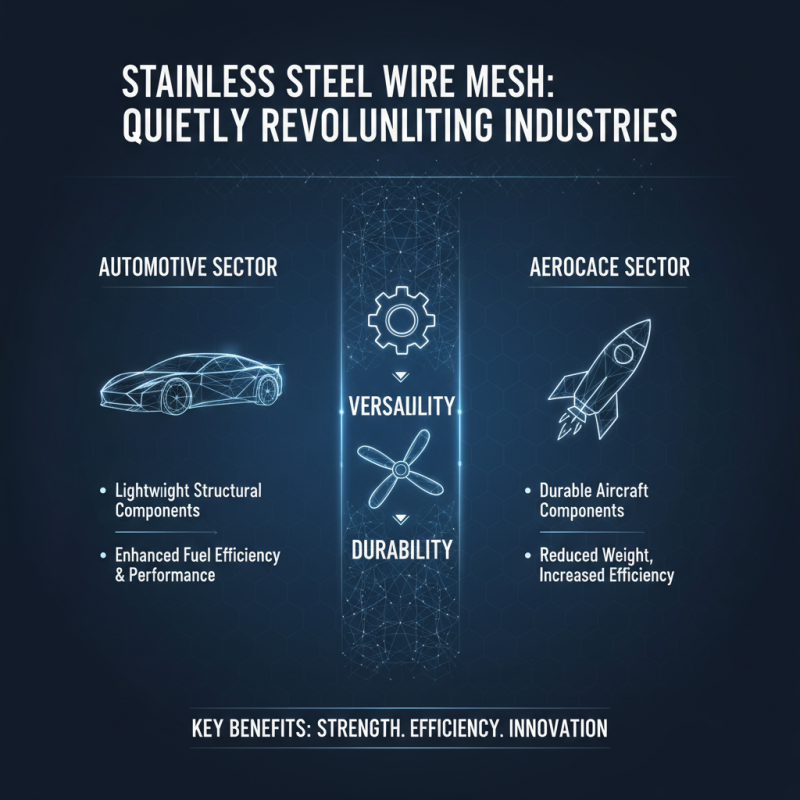

Innovative Uses of Stainless Steel Wire Mesh in Automotive and Aerospace

Stainless steel wire mesh is quietly transforming the automotive and aerospace sectors. Its durability and versatility make it an ideal choice for various applications. In automotive design, manufacturers are now using this material for lightweight structural components. This shift not only reduces overall vehicle weight but also enhances fuel efficiency.

In aerospace, the focus is shifting to safety. Stainless steel wire mesh provides an effective barrier against foreign objects. It helps protect sensitive equipment while maintaining airflow. However, some engineers still question the balance between weight and strength. Research is ongoing to optimize this material for the best performance.

Innovative uses continue to emerge. For example, stainless steel wire mesh is being adapted for interior designs, improving aesthetics while ensuring safety. Yet, challenges remain in scaling production without sacrificing quality. The industry must reflect on its approaches to fully harness the benefits of this material.

Trends in Food Processing and Packaging with Stainless Steel Wire Mesh

The food processing industry is evolving rapidly. Stainless steel wire mesh plays a crucial role in this transformation. It is widely used for filtration, separation, and support in processing lines. Its durability makes it a top choice for many applications.

In packaging, stainless steel provides safety and hygiene. Unlike plastics, it does not leach harmful chemicals. It is easy to clean and maintain. However, reliance on such materials should be reconsidered. The environmental impact of metal production is significant. Are we truly ready to make sustainable changes?

Innovations are emerging. New mesh designs enhance efficiency. Adaptive technologies could further improve performance. Yet, challenges remain. Not all businesses have access to these advancements. Cost and complexity can be barriers. Reflection is crucial for progress in this field.

Sustainable Practices and the Future of Stainless Steel Wire Mesh Production

The future of stainless steel wire mesh production hinges on sustainable practices. As industries evolve, eco-friendly methods are gaining traction. Recycling stainless steel reduces waste significantly. It also conserves resources, paving the way for greener production processes.

Incorporating renewable energy in manufacturing is critical. Many facilities are exploring solar and wind power. Adopting these practices is not just beneficial; it creates a necessity for change. However, not all manufacturers are on board yet. Some still rely heavily on traditional energy sources, which raises concerns.

Moreover, the use of recycled materials can enhance product quality. But the challenge lies in ensuring a consistent supply of high-quality scrap. It requires collaboration among suppliers and manufacturers. There’s room for improvement here. We must prioritize sustainable sourcing to benefit future generations.

Related Posts

-

Top 10 Best Stainless Steel Wire Mesh Options for Your Projects?

-

Why You Should Choose Wire Cloth for Your Industrial Filter Needs

-

2026 How to Choose the Best Stainless Steel Screen for Your Needs?

-

Why Stainless Steel Mesh Screens Are Essential for Your Home and Industry Needs

-

10 Best Stainless Steel Mesh Options for Versatile Applications

-

Why is Welded Wire Mesh Essential for Construction and Agriculture?