Best Small Wire Brush Options for Cleaning and Maintenance in 2025

When it comes to cleaning and maintenance tasks, a small wire brush is an indispensable tool for both professionals and DIY enthusiasts alike. Its compact size allows for precision and versatility, making it ideal for tackling a variety of applications, such as removing rust, cleaning intricate surfaces, and preparing materials for painting or welding. As we look ahead to 2025, the demand for efficient and effective cleaning tools continues to grow, leading to innovations and enhancements in small wire brush designs that cater to diverse needs.

In this exploration of the best small wire brush options available, we will delve into the various features and functionalities that make these brushes stand out in a crowded marketplace. From the type of bristles to handle ergonomics, understanding the nuances of each option will empower users to select the right brush for their specific cleaning and maintenance tasks. As we navigate through this topic, the goal is to equip readers with the knowledge needed to make informed decisions, ensuring that their cleaning endeavors are both efficient and effective.

Understanding Small Wire Brushes: Types and Uses

Small wire brushes are essential tools for a variety of cleaning and maintenance tasks. These brushes come in different types designed for specific applications, including brass, steel, and stainless steel bristles. A report by the Global Wire Brush Market indicates a projected growth in demand for these tools, fueled by increasing maintenance requirements in automotive, industrial, and DIY sectors. Each type of wire brush offers unique advantages; for instance, brass brushes are commonly used on softer materials to prevent scratching, while stainless steel options are ideal for tougher surfaces.

When considering the uses of small wire brushes, their versatility emerges as a key factor. They are employed not just for removing rust and paint from metal surfaces but also for cleaning machinery, tools, and even household items. According to industry data, over 60% of professionals in the maintenance sector prefer using wire brushes for their efficiency and effectiveness in achieving a clean finish. Understanding the proper type and use of a small wire brush can greatly enhance the ease and quality of various cleaning tasks, making it an invaluable addition to any toolbox.

Factors to Consider When Choosing a Small Wire Brush

When selecting a small wire brush for cleaning and maintenance, several key factors should guide your decision. One of the most critical elements is the bristle material. Steel bristles are ideal for heavy-duty tasks, effectively removing rust and debris from tough surfaces, while brass or nylon bristles are better suited for delicate materials, preventing scratches while still offering efficient cleaning capabilities. According to a recent industry report, the demand for wire brushes has increased by 15% in the past year across various sectors, indicating the crucial role these tools play in maintenance routines.

Another important consideration is the brush's size and handle. Ergonomic handles that provide a comfortable grip can significantly enhance usability, especially during prolonged tasks. Research shows that tools designed with user comfort in mind can reduce fatigue by up to 30%, making them more effective in professional settings. Additionally, brush head size affects the areas that can be cleaned; smaller brushes excel in tight spaces, while larger ones cover broader areas. As maintenance needs evolve, investing in the right small wire brush tailored to specific cleaning tasks can streamline efficiency and ensure optimal results.

Top Brands and Models for Small Wire Brushes in 2025

When it comes to cleaning and maintenance in 2025, small wire brushes are an indispensable tool for various tasks, from automotive upkeep to detailed household cleaning. Considering the evolving needs of users, top brands have introduced innovative designs focusing on durability and efficiency. These brushes typically feature high-quality bristles that provide excellent scrubbing power without damaging the surface underneath. Many models also include ergonomic handles, ensuring a comfortable grip during extended use.

In the competitive market, several popular options are emerging that stand out for their performance and versatility. Some brushes come with interchangeable heads, allowing users to switch between different bristle types for specific cleaning tasks. Additionally, features like rust-resistant coatings and compact sizes enhance their practicality, making them ideal for tight spaces or intricate areas.

As consumers seek reliable tools for their maintenance needs, these top models are tailored to meet a range of cleaning challenges while ensuring reliability and ease of use.

Maintenance Tips for Prolonging the Life of Your Small Wire Brush

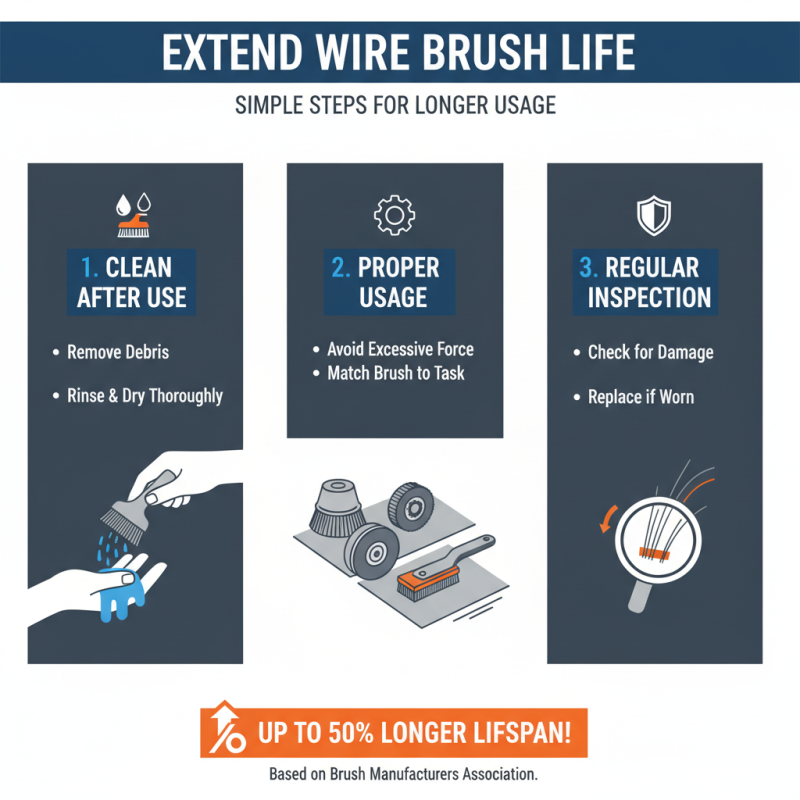

Maintaining the longevity of your small wire brush requires a combination of proper usage and consistent care. According to the Brush Manufacturers Association, regular maintenance can extend the lifespan of wire brushes by up to 50%. One of the key practices is to clean the brush immediately after use. This prevents debris and grime from becoming embedded in the bristles, which can compromise their effectiveness during future cleaning tasks. A simple rinse with water followed by thorough drying can make a significant difference in maintaining the bristles’ integrity.

Additionally, it’s crucial to store your small wire brush correctly to protect it from damage. The American Society of Mechanical Engineers emphasizes that brushes should be kept in a dry, clean environment, away from direct sunlight and extreme temperatures. Keeping the brush in a protective holder or case can also prevent the bristles from bending or fracturing. By following these maintenance tips, users can not only enhance the performance of their tools but also ensure they remain effective for years to come, ultimately leading to more efficient cleaning and maintenance tasks.

Safety Guidelines for Using Small Wire Brushes Effectively

When using small wire brushes for cleaning and maintenance, adhering to safety guidelines is crucial to ensure both effective results and personal protection. Always wear protective gear, such as safety goggles and gloves, to prevent injury from flying debris or sharp wire bristles. Long-sleeved clothing can also provide an added layer of protection against potential scratches and cuts while working with these tools. Additionally, use a mask or respirator if there is a risk of inhaling dust or particles, especially when working in confined spaces.

It’s important to select the right type of wire brush for the specific surface material and intended cleaning application. Brushes with softer bristles can be suitable for more delicate surfaces, while tougher bristles are ideal for heavier-duty cleaning tasks. Maintain a stable grip on the handle and operate the brush at a suitable angle to prevent slipping and ensure controlled movements. Regularly inspect the brush for any signs of wear or damage, as using a compromised tool can lead to accidents. Following these safety precautions will not only enhance the effectiveness of small wire brushes but also ensure a safer working environment.

Best Small Wire Brush Options for Cleaning and Maintenance in 2025

| Brush Type | Bristle Material | Size (inches) | Best Use | Safety Rating |

|---|---|---|---|---|

| Flat Wire Brush | Steel | 5 x 1 | Removing rust | A |

| Round Wire Brush | Brass | 4 x 2 | Precision cleaning | B |

| Detail Brush | Nylon | 6 x 0.5 | Textile surfaces | A |

| Power Brush | Stainless Steel | 3 x 1.5 | Heavy-duty cleaning | A |

| Mini Wire Brush | Carbon Steel | 4 x 1 | General cleaning | B |

Related Posts

-

10 Essential Tips for Using a Wire Brush Effectively in Your Projects

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

Top 10 Wire Brush Drill Attachments for Efficient Cleaning and Stripping

-

2025 Top 5 Stainless Steel Wire Rope Trends You Need to Know