10 Best Stainless Steel Mesh Options for Versatile Applications

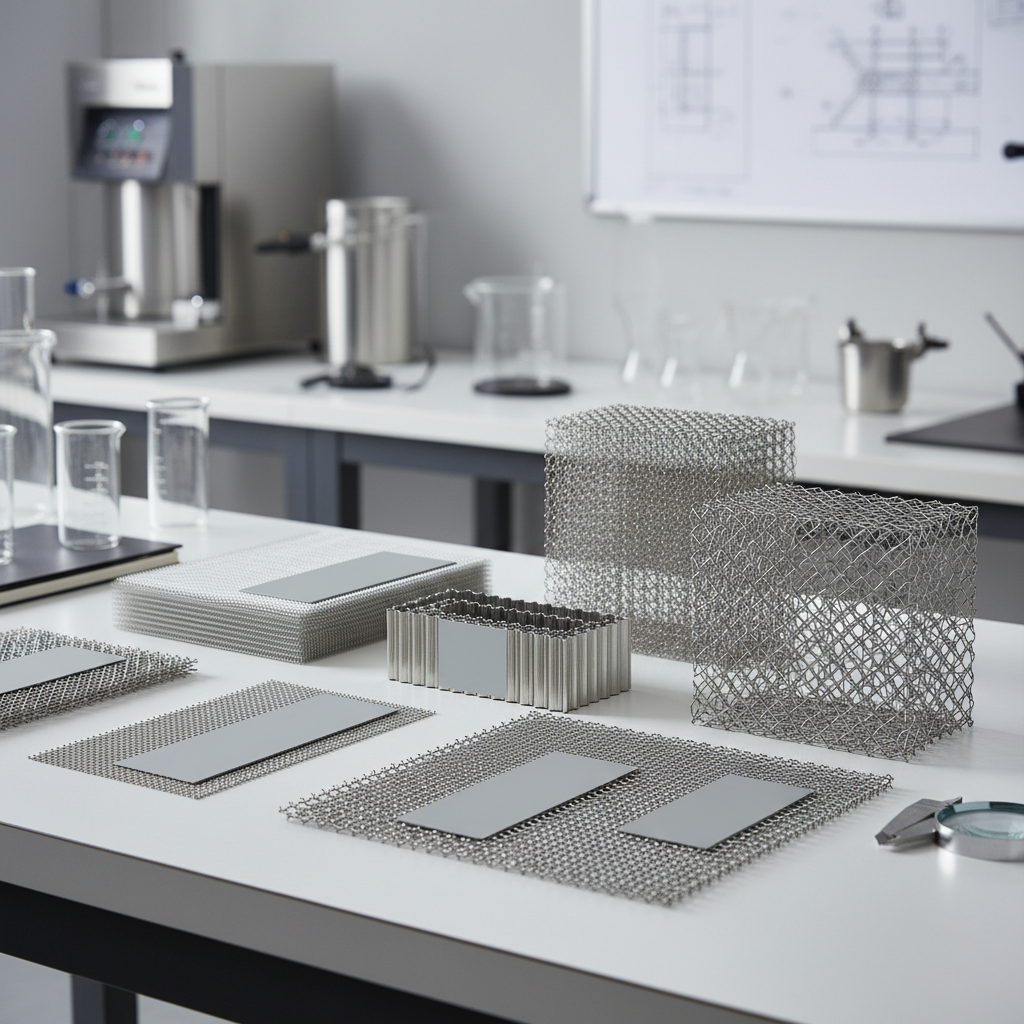

In the realm of industrial materials, stainless steel mesh stands out as a versatile and reliable choice for a plethora of applications. According to renowned expert in material science, Dr. Emily Carter, "The unique properties of stainless steel mesh not only provide strength and durability but also ensure excellent performance across diverse environments." This highlights the pivotal role that stainless steel mesh plays in various sectors, from construction and manufacturing to filtration and safety.

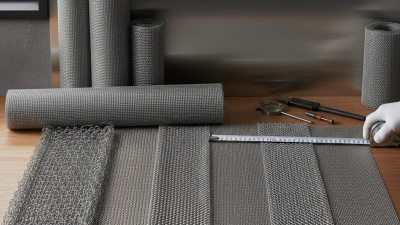

As industries evolve, the demand for high-quality stainless steel mesh continues to rise, prompting manufacturers to innovate and improve their offerings. The versatility of this material allows it to be used in an array of applications, from architectural facades to industrial screens. In this article, we will explore the top five stainless steel mesh options available in the market today, showcasing their unique features, benefits, and the specific applications they excel in.

Ultimately, understanding the best stainless steel mesh options can greatly enhance both functionality and aesthetic appeal in any project. Whether you're an architect seeking to design a striking building or an engineer in need of reliable filtration solutions, the right stainless steel mesh can make all the difference. Join us as we delve into the top contenders in the stainless steel mesh landscape.

Top Features to Consider When Choosing Stainless Steel Mesh

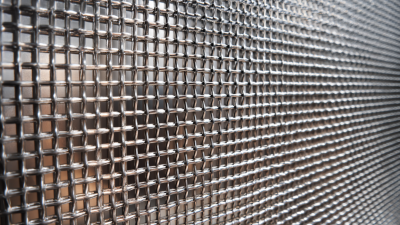

When selecting stainless steel mesh for various applications, several key features come into play to ensure optimal performance and durability. One of the most critical factors is the mesh size. According to the Industrial Fabric Association International, the right mesh size not only impacts filtration efficiency but also influences the flow rate of liquids and gases through the material. A finer mesh is ideal for filtering out small particles, while a coarser mesh can provide better airflow for applications like ventilation systems.

Additionally, the grade of stainless steel is paramount. For instance, 316 stainless steel is often recommended for environments exposed to harsh chemicals or saltwater due to its superior corrosion resistance, as highlighted by the National Association of Corrosion Engineers. It is also advisable to consider the wire diameter, which affects the strength and flexibility of the mesh. A thicker wire can enhance durability in high-stress applications, making it essential for industries such as construction and manufacturing where robustness is a necessity. A comprehensive understanding of these features can significantly enhance the selection process for an ideal stainless steel mesh solution.

Versatile Applications of Stainless Steel Mesh in Various Industries

Stainless steel mesh has emerged as a pivotal component across various industries due to its durability, corrosion resistance, and versatile applications. In the manufacturing sector, stainless steel mesh is widely utilized for filtration systems. These systems are essential for separating impurities from liquids and gases, ensuring product quality and assisting in compliance with stringent industry regulations. The ability of stainless steel mesh to withstand high temperatures and corrosive environments makes it an ideal choice for applications ranging from food processing to chemical manufacturing.

Moreover, the construction and architectural industries benefit significantly from stainless steel mesh's strength and aesthetic appeal. It is often employed in facades, railings, and even as decorative elements in modern building designs. In addition to its practical uses, stainless steel mesh contributes to safety and accessibility in urban environments. Its lightweight yet robust structure provides essential support in various applications without compromising on design. This versatility illustrates why stainless steel mesh remains a preferred option across multiple sectors, catering to both functional and aesthetic needs.

10 Best Stainless Steel Mesh Options for Versatile Applications

| Mesh Type | Opening Size (mm) | Wire Diameter (mm) | Application | Industry |

|---|---|---|---|---|

| Woven Wire Mesh | 1.0 | 0.5 | Filtration | Chemical |

| Perforated Metal | 2.5 | 1.0 | Walking Paths | Construction |

| Expanded Metal | 3.0 | 1.5 | Grating | Manufacturing |

| Sheet Metal Screen | 1.5 | 0.8 | Ventilation | HVAC |

| Mesh Fencing | 5.0 | 2.0 | Security | Agriculture |

| Safety Mesh | 2.0 | 1.0 | Equipment Protection | Manufacturing |

| Architectural Mesh | 4.0 | 1.2 | Decorative Screens | Architecture |

| Filter Mesh | 0.5 | 0.3 | Water Filtration | Water Treatment |

| Grid Mesh | 10.0 | 2.5 | Grain Storage | Food Industry |

| Industrial Mesh | 3.5 | 1.0 | Conveyor Systems | Logistics |

Comparative Analysis of the Best Stainless Steel Mesh Brands

When exploring the top stainless steel mesh options available in the market, a comparative analysis reveals significant variances among leading brands. According to a recent industry report by Grand View Research, the global stainless steel mesh market was valued at approximately $1.6 billion in 2021, with expectations of steady growth, driven by increased demand in various sectors, including food processing, pharmaceuticals, and aerospace. This growth reflects the importance of quality and functionality in selecting the right stainless steel mesh for specific applications.

Brands such as McNichols and WireCrafters dominate the landscape, offering a range of mesh types tailored for diverse uses. McNichols, known for its various mesh patterns and custom solutions, reported a 15% increase in sales in 2022, attributed to the surge in industrial applications. WireCrafters, on the other hand, emphasizes the strength and durability of their products, which have been tested to withstand extreme conditions, setting them apart in competitive analysis. Their meshes have a tensile strength often exceeding 70,000 psi, making them ideal for high-stress environments. Such data not only illustrates the competitive nature of the stainless steel mesh industry but also highlights the importance of making informed choices based on performance metrics and application requirements.

Maintenance Tips for Prolonging the Life of Stainless Steel Mesh

When it comes to maintaining stainless steel mesh, proper care is essential for extending its lifespan and ensuring it functions optimally across various applications. Regular cleaning is one of the most crucial steps. It's advisable to clean the mesh while it's still warm after use, as this prevents food particles or residues from hardening and becoming more difficult to remove. Using mild detergents and avoiding abrasive scrubbers will help preserve the surface integrity, ensuring the mesh retains its shine and does not become scratched.

In addition to regular cleaning, periodic inspections are vital. Just as household appliances require maintenance to function efficiently, stainless steel mesh also benefits from being checked for any signs of wear or damage. Addressing issues like corrosion as soon as they are spotted can greatly prolong the mesh's usefulness. Furthermore, storing stainless steel mesh in a dry and well-ventilated area when not in use can prevent moisture accumulation and rust, ultimately enhancing its durability and reliability for various applications.

Cost-Effective Solutions: Budget-Friendly Stainless Steel Mesh Options

Stainless steel mesh offers a versatile solution for various applications, from industrial uses to DIY projects. According to a report by Market Research Future, the global market for stainless steel mesh is projected to grow significantly, driven by its durability and resistance to corrosion. For budget-conscious consumers, there are numerous cost-effective options available that do not compromise on quality.

One of the top selections in affordable stainless steel mesh is the 304 grade, known for its excellent resistance to oxidation and high temperatures, making it ideal for both indoor and outdoor applications. Studies indicate that using 304 stainless steel mesh can enhance the durability of products while still being a sustainable choice, as it can be recycled without losing integrity. Furthermore, suppliers are increasingly providing smaller dimensions and custom cut pieces at competitive prices, allowing for greater flexibility in project budgets. This affordability combined with the material's longevity ensures that stainless steel mesh remains a favorable choice among various industries.

Related Posts

-

Why Stainless Steel Mesh Screens Are Essential for Your Home and Industry Needs

-

2025 How to Choose the Best Stainless Steel Mesh Screen for Your Needs

-

Discovering the Versatility and Durability of 304 Stainless Steel in Modern Applications

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Discovering the Versatility of 316 Stainless Steel: Applications You Never Knew About

-

Top 10 Stainless Steel Supplier Factors Influencing Market Growth and Demand in 2023