2026 Best Stainless Steel Woven Wire Mesh Options Explained?

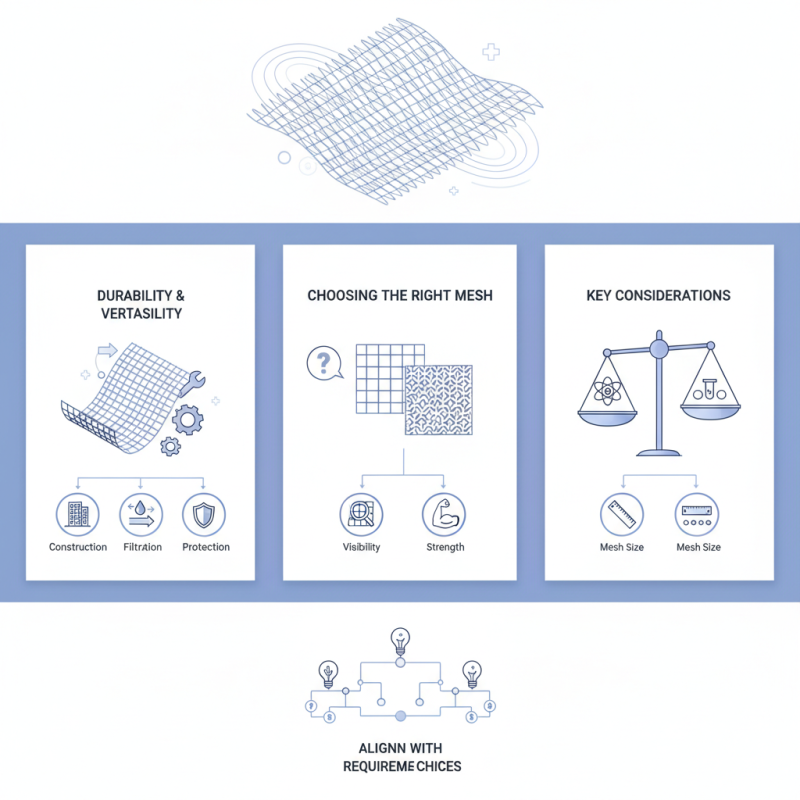

When it comes to durable materials, stainless steel woven wire mesh stands out. This versatile product offers strength and flexibility. Many industries rely on it for various applications. From construction to filtration, its utility is evident.

Choosing the best stainless steel woven wire mesh can be challenging. There are numerous options available, each serving specific needs. Quality matters, but so does the choice of weave. Some designs provide greater visibility, while others prioritize strength.

Evaluating the best choices involves more than just specifications. One must consider factors like corrosion resistance and mesh size. It’s crucial to reflect on how these elements align with your particular requirements. Despite the wealth of options, making the right choice can often be unclear. This guide aims to clarify those choices and highlight key aspects of stainless steel woven wire mesh.

Overview of Stainless Steel Woven Wire Mesh Types

Stainless steel woven wire mesh comes in various types, each serving unique purposes. One common type is the plain weave mesh. It features a grid pattern where the warp and weft wires are of equal diameter. This design provides strength and a good level of filtration. Often used in architectural applications, it allows for visibility while retaining structural integrity.

Another type is the twill weave mesh, which offers enhanced flexibility. The wires pass over two and under two others, creating a diagonal pattern. This type is ideal for applications needing greater durability and resistance to abrasion. When examining mesh options, consider the specific needs of your project. Some types provide better filtration, while others excel in strength.

It's important to reflect on your choice of mesh type. Sometimes, decisions are guided more by appearance than functionality. Understanding the application is crucial. A visually appealing mesh may not always meet practical needs. Design and utility should go hand in hand, leading to a more effective selection process.

Key Applications of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is widely used in various industries due to its strength and versatility. This material excels in applications like filtration, where its durability and corrosion resistance ensure long-lasting performance. According to a recent industry report, the global market for stainless steel mesh is projected to reach $1.7 billion by 2026. This value indicates a growing demand across sectors including food processing, pharmaceuticals, and construction.

In construction, stainless steel wire mesh is essential for reinforcing concrete, preventing cracking and increasing structural integrity. It's also commonly used in architectural designs, providing both aesthetic appeal and functional benefits. The mesh allows for natural light while maintaining security. For filtration purposes, industries use this mesh to separate particles from liquids and gases, highlighting its versatility.

Tip: When selecting stainless steel woven wire mesh, consider the mesh size and wire gauge for your specific application. Incorrect choices can lead to inefficiencies, requiring costly adjustments later. Remember, regular maintenance is crucial in environments with high exposure to corrosive elements. It’s not just about installation; ongoing care will ensure optimal performance and longevity.

2026 Best Stainless Steel Woven Wire Mesh Options

Factors to Consider When Choosing Woven Wire Mesh

When selecting woven wire mesh, consider its intended use. Different applications demand different specifications. For example, screens for food processing require strict hygiene standards. In industrial settings, durability is key. The stronger the material, the longer it lasts. This choice impacts safety and efficiency profoundly.

Material types are crucial. Stainless steel is popular for its resistance to corrosion. But not all stainless steel is created equal. Know the grades. Some might be more suitable for specific environments than others. Evaluate environmental factors like exposure to chemicals or extreme temperatures. This can alter the performance of the mesh over time.

**Tips:** Always sample materials if possible. Testing can reveal flaws before larger investments. Also, reflect on your specific needs. Sometimes, a less common wire gauge might be more beneficial. Be open to adjusting initial choices. Continuous improvement is essential in mesh selections.

2026 Best Stainless Steel Woven Wire Mesh Options Explained

| Mesh Type | Wire Diameter (mm) | Opening Size (mm) | Weave Pattern | Applications |

|---|---|---|---|---|

| Plain Woven | 0.5 | 1.0 | Plain | Filtration, Food Processing |

| Twill Woven | 0.8 | 1.2 | Twill | Industrial Filters, Architectural |

| Dutch Weave | 0.6 | 0.8 | Dutch | High-Pressure Applications, Oil & Gas |

| Safety Mesh | 1.0 | 1.5 | Welded | Guard Rails, Window Screens |

| Electroformed Mesh | 0.2 | 0.3 | Electroformed | Precision Filtration, Laboratory Use |

Top Brands and Products for Stainless Steel Woven Wire Mesh in 2026

In 2026, choosing the right stainless steel woven wire mesh can be overwhelming. Various options are available, each with unique features. This type of mesh is known for its durability. It's used in a wide range of applications, from industrial to domestic. The choice often depends on specific needs.

Some products stand out in terms of versatility and strength. Heavy-duty options offer excellent resistance to corrosion. Lightweight choices can be ideal for less demanding uses. Many consumers appreciate the aesthetic appeal of fine weaves. They are often used in decorative screens or partitions. Performance, however, can vary significantly.

Quality is another essential factor to consider. Not all products deliver the expected results. Some may not hold up as advertised over time. It’s crucial to research and compare different options. Reviews often highlight both positives and negatives. Finding the perfect fit might take time and patience. Testing small samples can lead to better decisions in the long run.

Maintenance and Durability of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is renowned for its durability and resistance to corrosion. This mesh type is widely used across various industries, including construction, food processing, and mining. In a recent industry report, it was noted that stainless steel mesh can last over 30 years under optimal conditions. However, environmental factors can diminish its lifespan.

Regular maintenance is crucial for maximizing the longevity of woven wire mesh. Simple cleaning routines can prevent buildup of dirt, debris, and corrosion. Proper storage is also vital; leaving mesh exposed to harsh weather can lead to premature wear. Neglecting these practices can result in significant repair costs.

Some users overlook the importance of regular inspections. Even minor damage can compromise the entire structure's integrity. Detecting issues early can save both time and money. It’s essential to adopt a proactive maintenance approach. While stainless steel woven wire mesh is resilient, it requires attention to detail to maintain its superior qualities.