2026 Best Steel Wire Types for Your Needs and Applications?

Choosing the right steel wire is crucial. Different applications require specific wire types for optimal performance. For 2026, several steel wire selections stand out.

Each type delivers distinct features. Some offer exceptional strength, while others provide flexibility. When deciding, consider your specific needs. Are you focusing on durability or malleability? Each choice shapes your project’s success.

Selecting steel wire is often challenging. Not all projects follow the same requirements. This diversity makes it important to reflect on your choices. Analyze the features of each wire type. Understanding their differences can lead to better decisions.

Understanding Different Types of Steel Wire and Their Properties

When selecting the best steel wire for your projects, understanding the different types is essential. Steel wire comes in various grades and finishes, each with specific properties. For instance, carbon steel wire offers high tensile strength, making it ideal for construction. Stainless steel wire, on the other hand, resists corrosion, suitable for outdoor applications.

According to industry reports, low-carbon steel wire is commonly used in manufacturing due to its ductility. It can be easily shaped and molded. High-carbon steel wire, however, is known for its rigidity and hardness, which is beneficial for applications like springs and automotive parts. It’s crucial to evaluate the intended use to determine the right wire type.

Tip: Always test the wire's tensile strength before use. Not all wires perform the same under pressure, which can lead to safety concerns. Another tip: consider the environmental conditions the wire will face. Moist environments require more resistant materials.

Understanding the properties of steel wire helps in making informed decisions. You'll want wires that align well with your specific application needs. Experiment with different types and observe their performance. This reflection can help improve future projects significantly.

Factors to Consider When Choosing Steel Wire for Specific Applications

When selecting steel wire, various factors come into play. Diameter is crucial; it affects the wire's strength and flexibility. A thicker wire can handle more weight but may be less pliable. Conversely, a thinner wire offers ease of handling but lacks strength. It’s essential to evaluate the balance between these attributes based on your project needs.

Material composition is another key consideration. Different alloys can enhance corrosion resistance or tensile strength. For applications exposed to harsh environments, choosing the right alloy can significantly prolong the wire's life. It’s easy to overlook this, but a poor choice here could lead to premature failure and costly replacements.

Finally, the intended application should guide your decision-making. For instance, wire used in construction requires different properties than wire for crafting. Assessing load requirements and environmental factors is indispensable. Ignoring these specifics may result in underperforming materials. Remember, taking the time to reflect on all aspects ensures a better fit for your needs.

2026 Best Steel Wire Types for Your Needs and Applications

| Steel Wire Type | Material Composition | Tensile Strength (MPa) | Common Applications | Corrosion Resistance |

|---|---|---|---|---|

| High Carbon Steel Wire | 0.6%-1.0% Carbon | 600-1200 | Manufacturing Springs, Tire Reinforcement | Low |

| Stainless Steel Wire | 18% Chromium, 8% Nickel | 500-1500 | Marine Applications, Medical Devices | High |

| Galvanized Steel Wire | Low Carbon Steel with Zinc Coating | 400-600 | Fencing, Wire Ropes | Moderate |

| Spring Steel Wire | 0.5%-0.9% Carbon with Manganese | 1000-2300 | Automotive Components, Industrial Springs | Low |

| Pre-Stressed Steel Wire | High Carbon with Special Coatings | 1500-2000 | Concrete Reinforcement | Moderate |

Common Applications of Steel Wire Across Various Industries

Steel wire is versatile and essential in various industries. Its applications range from construction to automotive. According to a 2022 report by Global Steel Wire Market, construction accounts for nearly 45% of steel wire usage. Steel wire is prominent in reinforcing concrete structures. This method enhances durability while ensuring structural integrity.

In the automotive sector, steel wire plays a crucial role in manufacturing components like springs and cables. Approximately 20% of steel wire is utilized here. These components demand high tensile strength. For instance, wire used in suspension systems must endure significant stress. Yet, the challenge lies in ensuring that the wire meets safety and performance standards.

The telecommunications industry also relies heavily on steel wire. Over 15% of steel wire is applied in communication lines. Its strength and conductivity make it ideal for supporting data transmission. However, the industry faces issues related to corrosion and degradation over time. The need for continuous innovation in wire treatments is evident. Balancing cost and performance remains a critical challenge.

Comparative Analysis of Steel Wire Types for Strength and Durability

When choosing steel wire types, understanding their strength and durability is crucial. Wire made from carbon steel is common. It offers excellent tensile strength. However, it is also prone to corrosion without proper treatment. For applications in hostile environments, stainless steel wire becomes a better option. It resists rust and performs well over time.

Another type to consider is galvanized steel wire. This wire is coated to enhance durability. It retains strength while providing additional protection from the elements. However, the coating can wear off, especially in abrasive settings. Coated wires may need more frequent replacements. In contrast, high-carbon wire may excel in strength but can be brittle. Finding a balance between strength and flexibility is essential.

Ultimately, each wire type serves different needs. Industries need to evaluate their specific requirements. The working environment plays a significant role in the decision-making process. Each choice has its challenges and benefits. Rethinking the application and maintenance of these wires can lead to better performance and longevity.

Maintenance Tips for Longevity of Steel Wire Products in Use

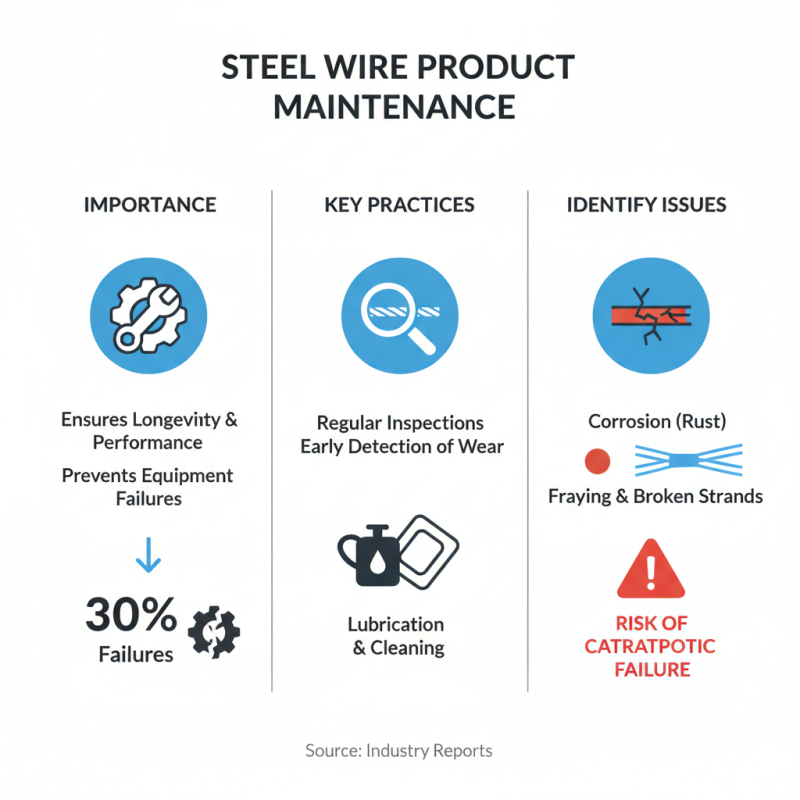

Proper maintenance of steel wire products is essential for ensuring their longevity and performance. According to industry reports, nearly 30% of equipment failures are linked to inadequate maintenance. Regular inspections can help identify wear and damage early. Look for signs of corrosion or fraying. These issues can lead to catastrophic failures if neglected.

Cleaning steel wire regularly is crucial. Dirt and debris can cause surface wear over time. Use a stiff brush or cloth for cleaning. Lubrication is often overlooked, but it prevents rust and eases operation. Choose lubricants that are appropriate for the specific environment in which the wire operates. Wet environments require different protection than dry ones.

Storing steel wire correctly also plays a vital role in its lifespan. Ideally, it should be kept in a dry place, protected from moisture. Humidity can accelerate corrosion. A maintained environment can increase the lifespan by 20%. Neglecting storage can lead to unexpected costs and shrink the lifespan significantly. Regular checks and proper handling of steel wire products can help avoid these pitfalls.

Related Posts

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

Top 10 Applications and Benefits of Steel Wire You Need to Know!

-

The Best Steel Wire Types for Your Projects and Applications?

-

Understanding the Essential Role of Steel Rope in Everyday Applications

-

Top Uses of Steel Cable in Everyday Applications How Does It Work?

-

10 Essential Tips for Choosing the Right Weld Mesh for Your Project?