The Best Steel Wire Types for Your Projects and Applications?

Steel wire plays a crucial role in various industries, including construction, automotive, and manufacturing. According to a report by the International Wire and Cable Association, the global steel wire market is projected to grow steadily, reaching $30 billion by 2025. This growth is driven by increasing demand for durable and high-strength materials.

Expert John T. Smith, a recognized authority in the wire production industry, emphasizes, “Choosing the right type of steel wire can significantly impact the performance and longevity of a project.” This statement highlights the importance of understanding the different types of steel wire available. Not all wires are created equal; they vary in tensile strength, corrosion resistance, and flexibility.

Mistaking one type for another could lead to failures in critical applications. For instance, using low-strength wire in high-stress situations can cause structural failures. As industries evolve, the need for specialized steel wire becomes even more apparent. Therefore, careful consideration of steel wire types is essential for successful outcomes in any project.

Understanding Different Types of Steel Wire Used in Construction Projects

When it comes to construction projects, choosing the right type of steel wire is crucial. Different steel wire types serve specific purposes. For example, mild steel wire is often used for general construction tasks. It is flexible and easy to handle. On the other hand, high-carbon steel wire is stronger but can be more challenging to work with. Knowing the properties and applications of each type can make a significant difference in your project's success.

Tips: Always consider the tensile strength of the wire. It affects its performance under stress. A wire that is too weak may fail. Use wire with the right coating to prevent rust. This can increase longevity.

Galvanized steel wire offers good corrosion resistance, making it ideal for outdoor applications. However, its rigidity can be a drawback in some projects. Another option is stainless steel wire. It’s more expensive but offers superior strength and durability. Be cautious; not all projects may require such high-end materials. Assess your needs carefully.

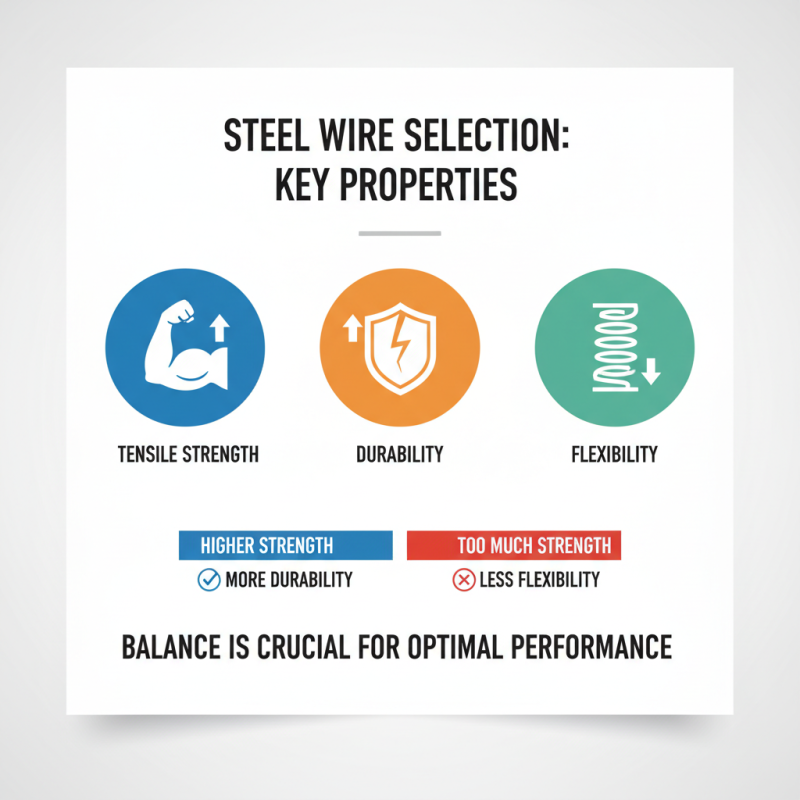

Key Properties to Consider When Choosing Steel Wire for Applications

When choosing steel wire for your projects, consider key properties. The wire's tensile strength is crucial. It determines how well the wire can withstand tension without breaking. A higher tensile strength often means more durability. However, too much strength can make the wire rigid and less flexible for certain applications.

Next, the wire's corrosion resistance matters. Some environments can lead to rust and deterioration. Protective coatings can help, but they might not always be practical. Remember, working with coated wire can mean losing some grip. So, think about what you need: flexibility or durability?

Diameter and weight also play roles. Thicker wires offer more strength but add weight. Lightweight wires are easier to handle but may not support heavy loads. The balance between these factors can be tricky. Each project demands different specifications, which is why reflection on your needs is vital.

Comparative Analysis of Carbon Steel, Stainless Steel, and Alloy Wire

When choosing the right steel wire, it's crucial to compare carbon steel, stainless steel, and alloy wire. Each type has unique qualities that affect performance in different projects. Carbon steel is known for its strength and affordability but can rust if not protected. This limitation can be a drawback in environments with moisture. However, it remains a favorite for structural applications.

On the other hand, stainless steel offers excellent corrosion resistance. This makes it suitable for outdoor projects or harsh environments. It's often more expensive than carbon steel, which can be a hurdle for budget-conscious individuals. Additionally, while stainless steel is strong, it may not always provide the same toughness as carbon steel in certain applications. As for alloy wire, it blends various elements to enhance specific properties. Yet, finding the right balance in an alloy can be tricky, requiring careful consideration.

In practice, selecting the right wire type involves challenges. For instance, understanding how environmental factors will affect wire performance is not always straightforward. Moreover, the specific requirements of a project may lead to unexpected choices. Sometimes, less expensive options yield better results than anticipated. Reflecting on these decisions can improve future projects.

Common Applications for Various Types of Steel Wire in Industry

When working with steel wire, it's essential to consider the specific applications within various industries.

Construction often relies on high-tensile steel wire, known for its

strength and durability. This wire is frequently used in reinforced concrete and as cables in bridges. The ability

to handle heavy loads makes it perfect for structural support.

In the automotive industry, low-carbon steel wire is widely used.

This flexible material can be easily bent and shaped into various components. It’s commonly found in springs,

wire forms, and even in the production of tires. While it performs well, some may find it less effective

for high-stress applications.

Additionally, stainless steel wire has gained popularity in the manufacturing

of kitchenware and medical devices. Its corrosion resistance is a key advantage. However,

challenges arise in terms of cost and fabrication difficulties.

Each type of steel wire has its strengths and weaknesses. Choosing the right type requires careful consideration

of the project's specific needs and goals.

Best Practices for Working with Steel Wire in DIY Projects and Repairs

Working with steel wire can elevate your DIY projects. However, using it correctly requires some know-how. When cutting steel wire, always wear gloves. The sharp ends can easily cause injuries. A wire cutter is essential, yet the size matters. Choose a cutter that suits the thickness. Using the wrong tool may lead to frustration and wasted materials.

Twisting and bending steel wire often results in strong connections. For making intricate shapes, a pair of pliers helps. But, if you overbend it, you might create weak points. Repeated stress on these weak areas can lead to failure in your project. Take breaks to rethink your design. If it does not feel right, do not proceed.

The final step is securing your steel wire. Using twists or knots can enhance strength. Ensure your knots are tight, yet be cautious. Too tight can cause the wire to snap. Reflect on what went well and what didn’t. Learning from mistakes is part of the crafting journey. Each project teaches you something new.

The Best Steel Wire Types for Your Projects and Applications

| Wire Type | Diameter (mm) | Tensile Strength (MPa) | Applications | Best Practices |

|---|---|---|---|---|

| Mild Steel Wire | 1.0 | 400 | Fencing, general repairs | Use corrosion-resistant coating for outdoor use |

| Stainless Steel Wire | 1.5 | 600 | Kitchen applications, surgical tools | Ensure proper welding techniques for strong joints |

| High Carbon Steel Wire | 1.2 | 1000 | Industrial applications, springs | Use protective gear when cutting or bending |

| Galvanized Steel Wire | 2.0 | 500 | Sewing, wire cages | Choose appropriate gauge for durability |

| Spring Steel Wire | 0.8 | 800 | Making springs, clips | Heat treat for maximum elasticity |

Related Posts

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

Top 10 Applications and Benefits of Steel Wire You Need to Know!

-

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects

-

Innovative Trends and Market Insights for Welded Wire Mesh at the 2025 China Import and Export Fair

-

Why You Should Choose Galvanized Wire Mesh for Your Next Project

-

The Versatility of Stainless Steel Cable: Applications, Benefits, and Innovations