2026 Best Welded Wire Mesh Applications and Benefits Explained?

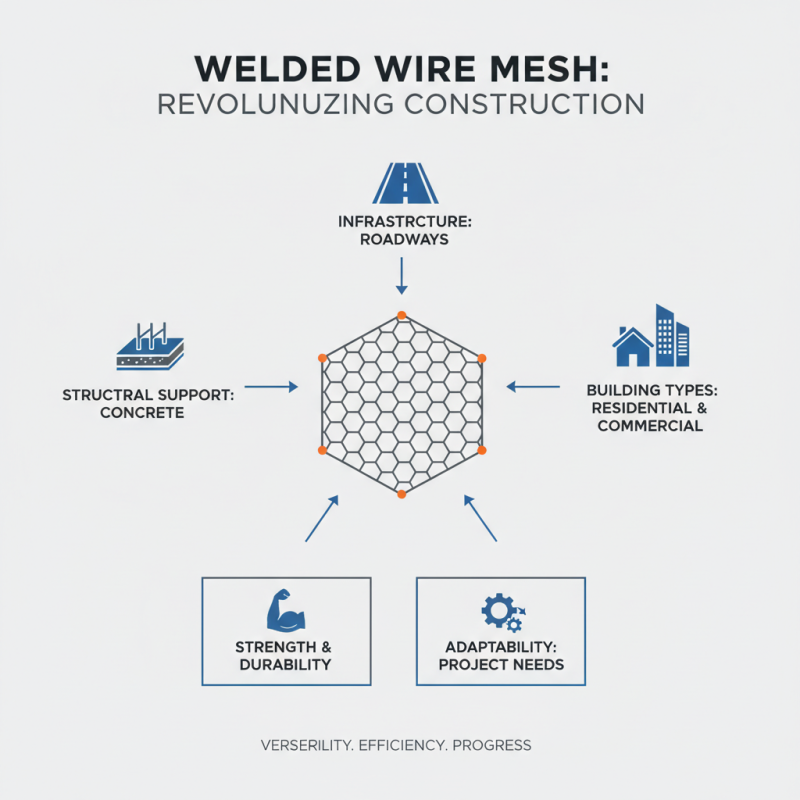

Welded wire mesh is a versatile material used in various industries. Its popularity stems from its strength and durability. In 2026, the applications of welded wire mesh continue to grow, showcasing its importance in construction, agriculture, and industrial sectors.

One significant advantage of welded wire mesh is its ease of installation. Builders appreciate how quickly it can be set up. Additionally, it offers excellent support for concrete structures. The precision in its manufacturing ensures reliable performance over time.

However, not all projects benefit from welded wire mesh. Certain applications may require alternatives. It's essential to assess the specific needs of a project. Understanding the limits of welded wire mesh can lead to better choices and desired outcomes. Evaluating its benefits helps in making informed decisions in practical scenarios.

2026 Trends in Welded Wire Mesh Applications

Welded wire mesh is gaining momentum across various industries in 2026. The construction sector is a primary user, with demand expected to grow by approximately 22% as urbanization escalates. This mesh provides essential support in concrete structures, enhancing stability and longevity. The integration of welded wire mesh in residential and commercial projects is becoming a standard practice.

In agriculture, welded wire mesh has proven invaluable, particularly in livestock fencing. A report indicates that installations are rising, contributing to a projected 15% increase in mesh sales. Interestingly, some farmers find it challenging to select the right gauge for their specific needs, leading to potential issues in durability. Meanwhile, the push towards sustainability encourages using recycled materials in welded wire mesh production, which could reduce the ecological footprint.

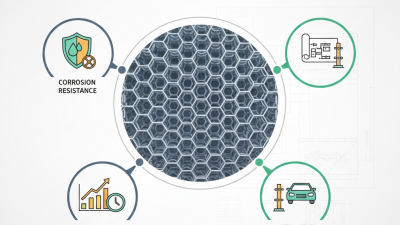

Robustness is a key benefit, yet not all types of welded wire mesh hold up equally. A survey revealed that 30% of users experienced premature corrosion. This highlights the necessity for careful selection based on environment and use. As trends shift, manufacturers might need to innovate to meet these challenges, ensuring their products remain reliable and effective for diverse applications.

Key Benefits of Using Welded Wire Mesh

Welded wire mesh has gained popularity for various applications due to its unique benefits. One significant advantage is its strength. The wires are welded at intersecting points, creating a sturdy, cohesive structure. This strength makes it ideal for fencing, animal enclosures, and reinforcement in construction. For instance, using welded wire mesh in concrete adds durability and prevents cracking.

Another benefit is versatility. Welded wire mesh can be designed in different sizes and shapes. This adaptability allows for customization in projects. You can use it in road construction, landscaping, or even crafts. The lightweight nature makes it easy to handle and install. However, one must pay attention to precise measurements during installation. A slight miscalculation could lead to structural issues later on.

Moreover, welded wire mesh offers long-term cost savings. Its durable nature reduces the need for frequent replacements. Homeowners and builders find this appealing. While the initial investment may be higher than other materials, the longevity can justify the cost. Yet, some may overlook the importance of maintenance. Regular checks for rust or damage are essential in ensuring its lifespan remains intact.

Common Industries Utilizing Welded Wire Mesh

Welded wire mesh finds extensive applications across various industries. It is a versatile solution, particularly valued in construction and agriculture. The global welded wire mesh market size was valued at approximately $5.3 billion in 2022, expected to grow steadily in the coming years. This growth underscores its importance for building infrastructure and securing crops.

In the construction industry, welded wire mesh serves multiple purposes. It reinforces concrete structures, improving their strength and durability. Many architects specify it for slabs, walls, and even foundations. In agriculture, it plays a crucial role in animal enclosures and garden fencing. Farmers appreciate its durability and cost-effectiveness, especially when protecting livestock and crops from pests.

Tips: When choosing welded wire mesh, consider the gauge and size of openings according to your project’s needs. Visit suppliers to see samples, as quality can vary significantly. Not all mesh meets safety standards, so verifying certifications is wise. While welded wire mesh is reliable, monitoring its condition regularly is essential. Over time, rust can weaken it, leading to potential failures.

Innovative Applications of Welded Wire Mesh in Construction

Welded wire mesh has transformed construction practices significantly. Its versatility is one of its greatest advantages. From supporting concrete structures to reinforcing roadways, it is seen in various applications. Builders often choose it for strength and durability. The mesh can adapt to different project needs, providing essential support in both residential and commercial buildings.

In innovative applications, welded wire mesh is also used for creating partitions. This allows for space division without sacrificing visibility. It is lightweight yet robust. Additionally, its application in landscaping enhances aesthetics and adds functionality. The installation process can be straightforward, but quality is crucial for long-term success. Some projects may overlook the details, leading to structural issues later.

Considering sustainability, using welded wire mesh can be beneficial. It reduces waste and minimizes resource use. However, it requires proper planning. Miscalculations can lead to increased costs. Understanding how to implement welded wire mesh effectively is important. Many still grapple with its best uses in complex designs.

Maintenance and Durability of Welded Wire Mesh Products

Welded wire mesh products are known for their durability. They resist corrosion and wear, making them ideal for various applications. However, one must recognize that maintenance is essential to prolong their lifespan. Regular inspections can identify signs of damage or rust. Ignoring these can lead to larger issues over time.

Cleaning welded wire mesh is straightforward but often overlooked. A simple wash can remove dirt and debris. In areas with extreme weather, more frequent maintenance is crucial. Don’t underestimate the impact of harsh elements. It’s important to be proactive rather than reactive. Relying solely on the mesh’s durability may lead to unexpected failures.

Proper storage is also significant. When not in use, keep the mesh in a dry place. This helps prevent moisture accumulation. Unfortunately, many users neglect this part. It’s a reminder that every element needs considerate handling. Reflecting on our practices helps ensure long-lasting performance in welded wire mesh.

2026 Best Welded Wire Mesh Applications and Benefits Explained

| Application | Benefits | Maintenance Level | Durability Rating (Years) |

|---|---|---|---|

| Garden Fencing | High visibility, secure barrier for pets and plants. | Low | 10 |

| Commercial Construction | Structural reinforcement, cost-effective. | Medium | 15 |

| Animal Enclosures | Safety for animals, easy visibility for monitoring. | Low | 12 |

| Construction Site Safety | Prevents unauthorized access, enhances site security. | Medium | 10 |

| HVAC Systems | Durability against corrosion and weather elements. | High | 20 |

Related Posts

-

Why You Should Choose Wire Cloth for Your Industrial Filter Needs

-

What is a Metal Mesh Screen and How is it Used in Different Applications

-

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects

-

2025 Top 5 Stainless Steel Wire Rope Trends You Need to Know

-

Why You Should Choose Galvanized Wire Mesh for Your Next Project

-

2025 How to Choose the Best MIG Wire for Optimal Welding Performance