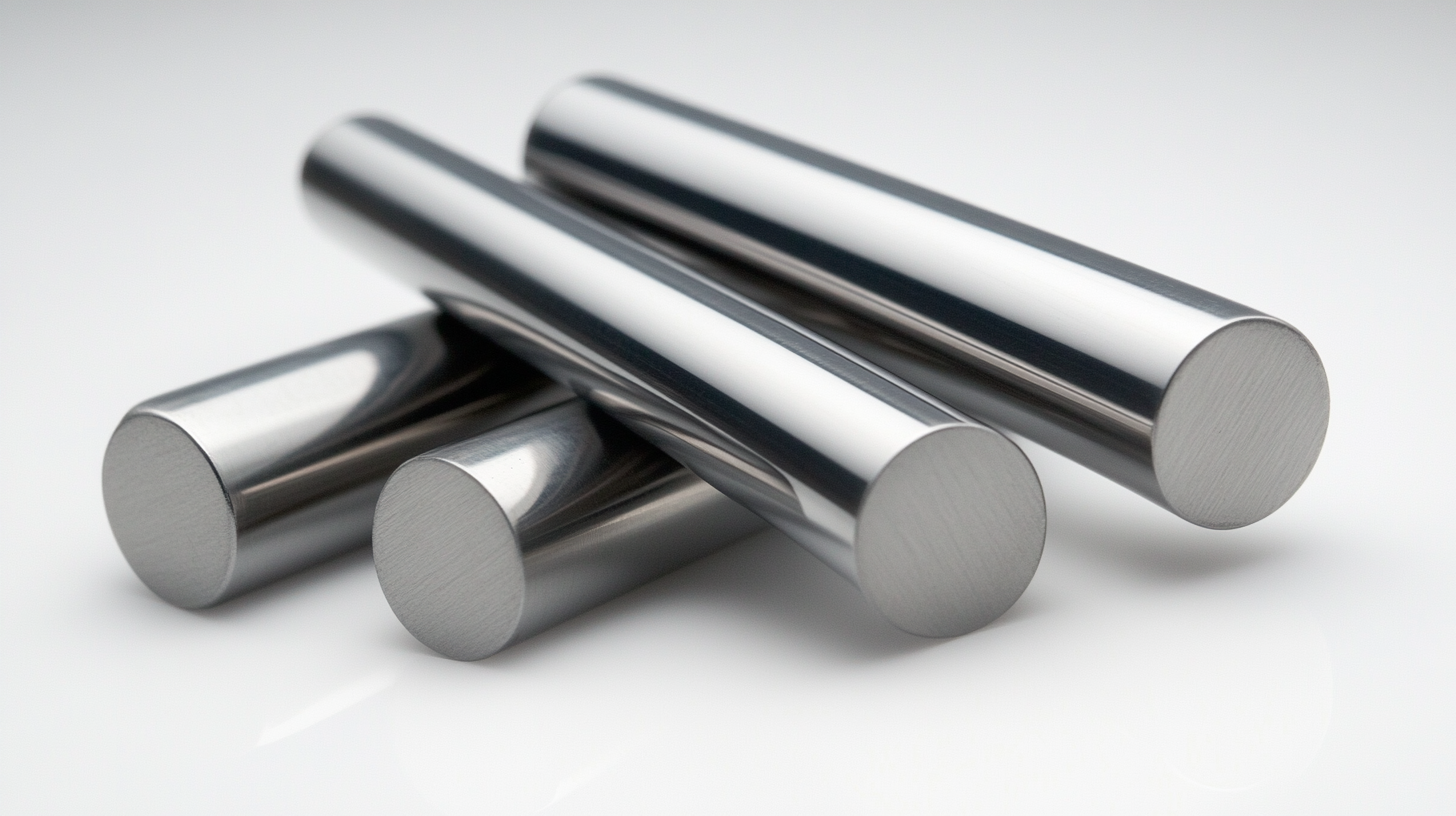

In recent years, China's manufacturing sector has positioned itself as a global leader in the production of premium stainless steel dowel pins, a vital component in various industries, from automotive to aerospace. According to a report by MarketsandMarkets, the global stainless steel pin market is projected to reach USD 2.2 billion by 2025, showcasing a steady growth rate driven by the increasing demand for high-quality, durable fastening solutions. With an emphasis on precision engineering and innovative manufacturing processes, China's output of stainless steel dowel pins exemplifies exceptional quality standards, meeting strict international regulations. This blog will delve into the comparative advantages of Chinese manufacturers in the premium stainless steel dowel pin market, exploring factors such as technological advancements, cost-effectiveness, and supply chain efficiencies that contribute to their rising prominence on the world stage.

China's journey to becoming a leader in premium stainless steel dowel pins is marked by a combination of advanced manufacturing techniques, strategic investments, and a commitment to quality. Initially, the country relied heavily on imported materials and technology, but through rigorous research and development, Chinese manufacturers began to innovate. They have perfected processes that enhance durability and precision, making their dowel pins a preferred choice for industries ranging from automotive to aerospace.

When considering the use of premium stainless steel dowel pins, it’s essential to focus on the quality of the material. Look for manufacturers that adhere to international standards and invest in state-of-the-art equipment. Not all dowel pins are created equal; those made from high-grade stainless steel tend to offer better resistance to corrosion and wear, ensuring longevity in various applications.

When considering the use of premium stainless steel dowel pins, it’s essential to focus on the quality of the material. Look for manufacturers that adhere to international standards and invest in state-of-the-art equipment. Not all dowel pins are created equal; those made from high-grade stainless steel tend to offer better resistance to corrosion and wear, ensuring longevity in various applications.

Additionally, be aware of the importance of proper sizing and fit. A well-fitted dowel pin can significantly affect the assembly's integrity. Always consult technical specifications before purchase to ensure compatibility with your project requirements. By following these tips, industries can fully leverage the exceptional capabilities of China's premium stainless steel dowel pins.

When it comes to the manufacturing of premium stainless steel dowel pins, the importance of quality standards cannot be overstated. These standards ensure that the dowel pins not only meet the functional requirements but also withstand the test of time and mechanical stresses. In China, leading manufacturers have implemented strict quality control processes that conform to international standards, which is crucial in establishing credibility and trust in the global market.

**Tip:** When looking for quality dowel pins, it’s essential to inquire about the manufacturer’s adherence to quality certifications such as ISO 9001. This ensures that the products have met rigorous industry standards.

Moreover, the choice of materials plays a significant role in the overall quality of dowel pins. High-grade stainless steel is preferred for its strength, corrosion resistance, and durability. Manufacturers in China utilize advanced technology and techniques to ensure that each dowel pin is produced with precision, ultimately contributing to enhanced performance in various applications.

**Tip:** Always request detailed product specifications and test reports to verify the material quality and manufacturing process, ensuring you receive dowel pins that will perform effectively in your projects.

This chart illustrates the tensile strength of various grades of stainless steel dowel pins manufactured in China. It highlights the importance of quality standards in the production process, showcasing how premium materials result in superior performance characteristics.

China's commitment to innovation in manufacturing has positioned the country as a leader in the production of premium stainless steel dowel pins. These essential components are crucial in various applications, from automotive to aerospace, where precision and durability are paramount. The innovative techniques employed in their manufacturing not only enhance quality but also streamline production processes, allowing China to meet global demand efficiently.

One of the key advancements in the production of stainless steel dowel pins is the use of advanced alloy compositions. By experimenting with different metal blends, manufacturers have developed pins that are not only resistant to corrosion but also exhibit superior strength and longevity. Furthermore, the implementation of automation and robotic technologies in the manufacturing process significantly reduces human error, leading to consistent quality across batches.

Additionally, China has increasingly focused on sustainability in its manufacturing practices. The introduction of eco-friendly methods, such as recycling wastewater and reducing energy consumption during production, underscores the country’s dedication to minimizing its environmental footprint. These improvements reflect a broader trend towards responsible manufacturing, ensuring that China's stainless steel dowel pins are not only premium in quality but also produced with an eye toward a sustainable future.

Dowel pins made from premium stainless steel are essential components across a broad spectrum of industries, including automotive, aerospace, and construction. Their robust mechanical properties make them ideal for applications that require precise alignment and secure fastening. According to a recent market analysis by Research and Markets, the global market for dowel pins is projected to reach $1.5 billion by 2026, driven by increasing demand for high-quality connectors and fasteners in various manufacturing processes.

In the automotive sector, stainless steel dowel pins are utilized for their corrosion resistance and strength, ensuring longevity under extreme conditions. Similarly, in aerospace applications, their precision and lightweight characteristics contribute to the overall efficiency and safety of aircraft manufacturing. Industries are increasingly recognizing the benefits of using premium materials to achieve durability while minimizing maintenance costs, consequently making stainless steel dowel pins a preferred choice.

**Tip:** When selecting dowel pins for your applications, ensure that you choose pins with the appropriate diameter and length for optimal fit and performance. **Tip:** Regularly assess the environmental conditions of your application to decide if you need surface-treated or hardened dowel pins, which can enhance their performance in specific environments.

As the global demand for premium stainless steel dowel pins continues to rise, several future trends are shaping the production landscape. Firstly, the industry is witnessing a significant shift towards automation and smart manufacturing techniques. These advancements not only streamline production processes but also enhance product quality and reduce labor costs. Consequently, manufacturers are better positioned to meet the increasing demand for precision-engineered dowel pins, particularly in sectors like automotive and aerospace where high-performance materials are crucial.

Additionally, sustainability is becoming a pivotal aspect of stainless steel manufacturing. Companies are exploring eco-friendly materials and energy-efficient processes to minimize their environmental impact. This trend aligns with the growing consumer expectation for sustainable products, thus driving innovation in material science and recycling technologies. As manufacturers in the Asia-Pacific region adapt to these trends, they are likely to boost their market share and enhance competitive advantages in the global market for stainless steel dowel pins over the coming years.

| Year | Global Market Size (USD Billion) | Production Volume (Million Units) | Growth Rate (%) | Key Trends |

|---|---|---|---|---|

| 2021 | 1.2 | 45 | 5.0 | Increased automation in production |

| 2022 | 1.4 | 50 | 6.0 | Sustainability initiatives in sourcing |

| 2023 | 1.6 | 55 | 7.5 | Focus on high-strength materials |

| 2024 | 1.8 | 60 | 8.0 | Expansion into new markets |