2025 How to Choose the Best Stainless Steel Mesh Screen for Your Needs

When it comes to selecting the ideal stainless steel mesh screen for your specific requirements, understanding the key factors involved in the decision-making process is crucial. Stainless steel mesh screens are widely recognized for their durability, versatility, and resistance to corrosion, making them an excellent choice for various applications, from industrial use to home improvement projects. In 2025, the market offers a plethora of options, each tailored to different needs and specifications.

In this guide, we will explore the essential considerations for choosing the best stainless steel mesh screen for your needs. From assessing the mesh size to understanding the different grades of stainless steel, we will provide valuable insights that will empower you to make an informed decision. Furthermore, we will address factors like the intended use, environmental conditions, and budget constraints, ensuring that you select a product that not only meets but exceeds expectations. By the end of this article, you will be equipped with the knowledge to confidently choose a stainless steel mesh screen that aligns perfectly with your project requirements.

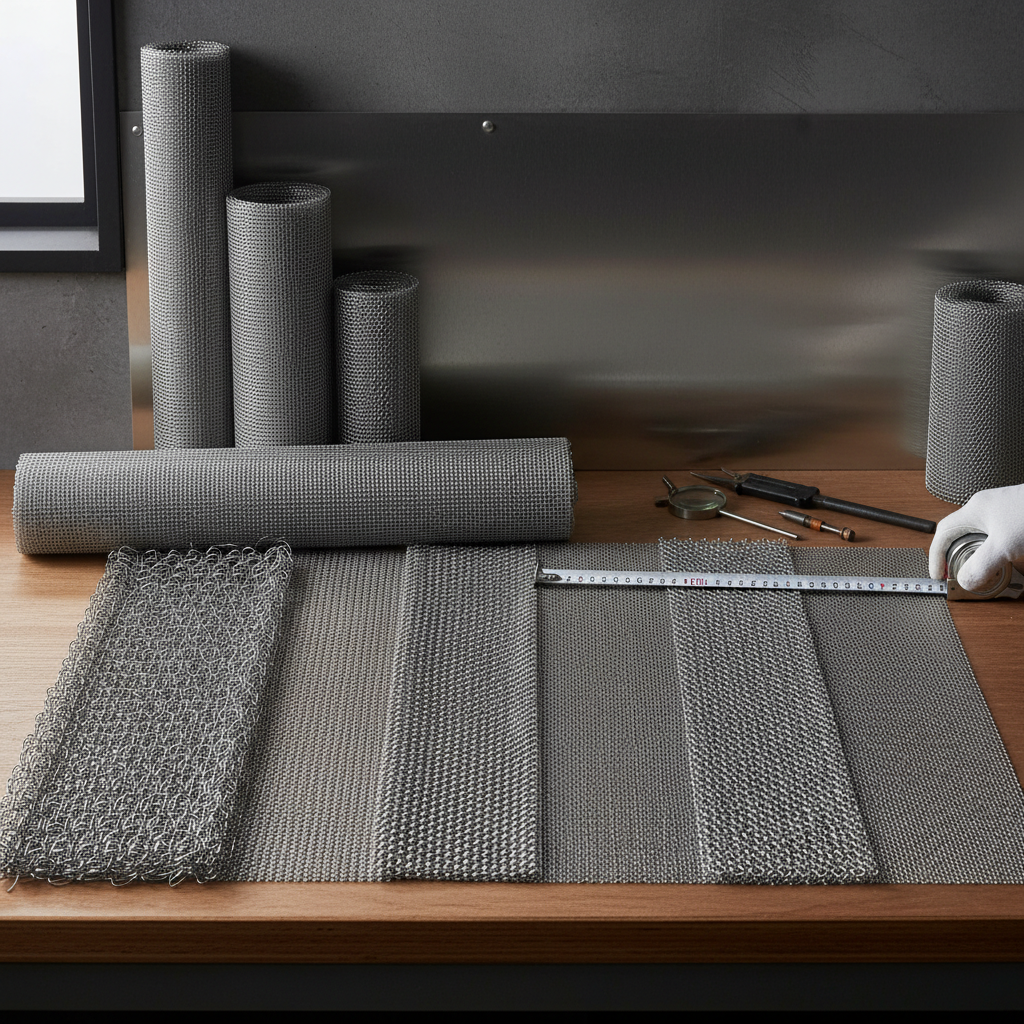

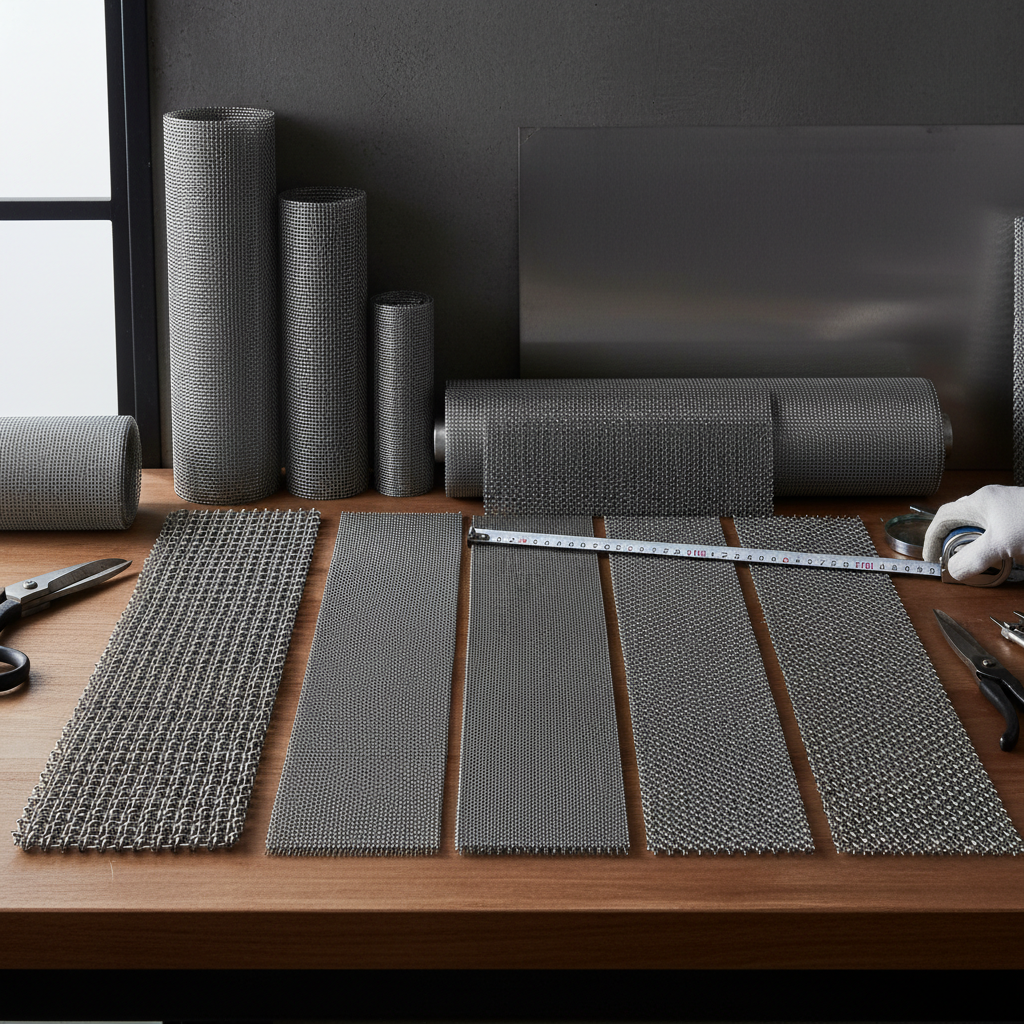

Understanding the Types of Stainless Steel Mesh Screens Available on the Market

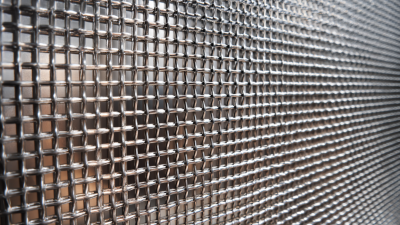

When considering the types of stainless steel mesh screens available on the market, it's essential to understand their classifications and applications. Stainless steel mesh screens are typically categorized based on wire diameter, mesh count, and weave type. The most common weave types include plain weave, twill weave, and Dutch weave. Each weave type serves different purposes; for instance, plain weave is versatile and commonly used for filtration, while twill weave provides higher strength and flexibility, making it suitable for more demanding applications.

Further classification can be made based on the size of the openings in the mesh. Coarse mesh screens are ideal for larger particles, making them perfect for industrial applications, while fine mesh screens are better suited for applications requiring precise filtration, such as medical or food processing industries. Additionally, the corrosion resistance and temperature tolerance of stainless steel mesh screens can vary depending on the specific stainless steel grade used, influencing their suitability for different environments. Understanding these distinctions is crucial in selecting the best stainless steel mesh screen to meet your specific needs.

Key Factors to Consider When Selecting Stainless Steel Mesh for Specific Applications

When selecting a stainless steel mesh screen, understanding the specific requirements of your application is crucial. Key factors to consider include the mesh size, wire diameter, and material grade. For instance, applications requiring filtration or separation will benefit from a finer mesh size, while those focused on structural integrity may prioritize a thicker wire diameter. According to a recent industry report by MarketsandMarkets, the demand for stainless steel mesh is projected to grow at a CAGR of 5.2% from 2023 to 2028, highlighting the increasing necessity for tailored solutions across various sectors.

Tip: Always check the corrosion resistance of the specific stainless steel grade. For example, 304 stainless steel is suitable for general purposes, but 316 stainless steel offers enhanced resistance to saltwater environments, making it ideal for marine applications.

Another crucial aspect is the mesh's weave pattern, which influences both strength and flexibility. A dutch weave is often recommended for high-pressure applications due to its durability, as indicated by research from the American Society for Testing and Materials (ASTM). Thus, carefully assessing these factors according to your unique needs will ensure you choose the best stainless steel mesh for optimal performance.

Comparative Analysis of Wire Diameter and Open Area in Stainless Steel Mesh Screens

When selecting the best stainless steel mesh screen for your needs, the wire diameter and open area are critical factors to consider. Wire diameter influences both the strength and the filtration capabilities of the mesh. Thicker wires provide enhanced durability and resistance to wear, making them ideal for heavy-duty applications. However, a larger wire diameter can reduce the open area, affecting the mesh’s ability to allow fluid or air passage. Therefore, finding the right balance between wire thickness and open area is essential for optimal performance.

On the other hand, the open area, which is defined as the percentage of the mesh that is not covered by wire, directly impacts flow rates and filtration efficiency. A higher open area facilitates better circulation while still maintaining the necessary filtration qualities. For applications requiring high flow rates without compromising on filtration, screens with a smaller wire diameter and larger open area are preferable. Conversely, for applications where structural integrity and robust filtration are paramount, a thicker wire mesh with a smaller open area may be the better choice. Understanding these elements will guide you in making an informed decision tailored to your specific requirements.

2025 How to Choose the Best Stainless Steel Mesh Screen for Your Needs - Comparative Analysis of Wire Diameter and Open Area in Stainless Steel Mesh Screens

| Mesh Type | Wire Diameter (mm) | Open Area (%) | Application |

|---|---|---|---|

| Standard Mesh | 0.5 | 50 | Filtration |

| Fine Mesh | 0.25 | 40 | Chemical Processing |

| Heavy Duty Mesh | 1.0 | 30 | Heavy Filtration |

| Ultra-Fine Mesh | 0.1 | 60 | Micro Filtration |

| Woven Wire Mesh | 0.35 | 45 | Screening |

Durability and Corrosion Resistance: How to Evaluate Stainless Steel Mesh Materials

When choosing a stainless steel mesh screen, evaluating its durability and corrosion resistance is crucial to ensure it meets your specific needs.

Stainless steel is renowned for its strength, but not all grades offer the same level of protection against environmental factors.

Look for high-quality alloys like 304 or 316 stainless steel. Type 316, for instance, contains molybdenum, which provides heightened corrosion resistance, particularly in marine or industrial settings where exposure to saltwater or chemicals is prevalent.

When choosing a stainless steel mesh screen, evaluating its durability and corrosion resistance is crucial to ensure it meets your specific needs.

Stainless steel is renowned for its strength, but not all grades offer the same level of protection against environmental factors.

Look for high-quality alloys like 304 or 316 stainless steel. Type 316, for instance, contains molybdenum, which provides heightened corrosion resistance, particularly in marine or industrial settings where exposure to saltwater or chemicals is prevalent.

Tips for evaluating stainless steel mesh materials: First, consider the application of the screen. If it will be used outdoors or in harsh conditions, prioritize corrosion-resistant grades. Additionally, check the wire diameter and mesh density; thicker wires and a tighter weave typically contribute to durability. Investigate the manufacturing process too, as welds and coatings can influence the overall lifespan of the mesh screen.

Ultimately, choosing the right stainless steel mesh screen is about balancing the material's strength with its resistance to corrosion. By understanding these factors and selecting the appropriate grade, you can ensure that your mesh screen will perform effectively for years to come.

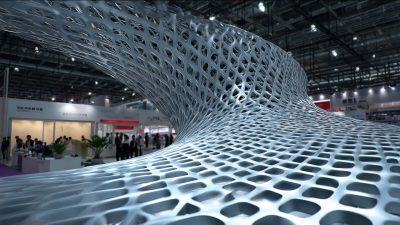

Industry Trends: Innovations in Stainless Steel Mesh Screen Technology for 2025

The stainless steel mesh screen industry is witnessing significant advancements as we approach 2025. One of the most notable trends is the introduction of eco-friendly production methods, which aim to reduce carbon footprints. According to a report from Grand View Research, the global stainless steel mesh market is projected to grow at a CAGR of 6.3% from 2022 to 2030. This growth is largely driven by the increasing demand for corrosion-resistant materials across various sectors, including construction, automotive, and food processing.

Moreover, innovations in filtration technology are enhancing the functionality of stainless steel mesh screens. The development of finer mesh sizes is enabling better filtration efficiency, which is increasingly crucial in industries focusing on food and beverage safety and pharmaceuticals. A recent study by MarketsandMarkets indicates that advanced filtration materials will dominate the market, leading to a shift in how manufacturers design their products. As companies invest in R&D, the market is likely to see specialized meshes that cater to specific applications, optimizing performance and productivity across diverse industrial needs.

Related Posts

-

Why Stainless Steel Mesh Screens Are Essential for Your Home and Industry Needs

-

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025

-

What is a Stainless Steel Supplier and How to Choose the Right One

-

Exploring the Versatility of Stainless Steel Wire: Applications in Everyday Life and Industry

-

Innovative Trends and Market Insights for Welded Wire Mesh at the 2025 China Import and Export Fair

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability