Why You Should Choose Galvanized Wire Mesh for Your Next Project

When it comes to selecting materials for construction and DIY projects, the choice of wire mesh can significantly impact durability, safety, and overall functionality. Among the various types available, galvanized wire mesh stands out as an exceptional choice due to its superior corrosion resistance and long-lasting performance. According to a recent industry report by MarketsandMarkets, the global wire mesh market is projected to reach USD 6.8 billion by 2026, fueled by the growing demand across construction, agriculture, and automotive sectors.

Galvanized wire mesh, specifically, is coated with zinc to enhance its durability, making it an ideal solution for various applications including fencing, enclosures, and support structures. A study by Research and Markets indicates that galvanized products experience a significantly reduced rate of oxidation compared to non-galvanized options, thereby ensuring a lifespan up to three times longer in many environments. This resilience against environmental factors makes galvanized wire mesh a preferred material choice for projects aimed at achieving both quality and longevity. As we explore the benefits of galvanized wire mesh, it becomes clear that it not only meets industry standards but also provides an innovative solution for your next project.

Benefits of Galvanized Wire Mesh for Structural Integrity and Durability

Galvanized wire mesh is a top choice for various construction projects due to its structural integrity and enhanced durability. When steel wire is galvanized, it undergoes a protective coating process that shields it from rust, oxidation, and corrosion. This feature makes it an ideal material for environments exposed to moisture and harsh weather conditions, ultimately prolonging the lifespan of structures. The strength of galvanized wire mesh also ensures that it can withstand significant weight and stress, making it essential for reinforcing concrete, fencing, and other applications.

Tips: When selecting galvanized wire mesh for your project, consider the gauge and mesh size based on your specific needs. A finer mesh will provide better support but may require more careful handling. Additionally, always check for a reputable supplier to ensure that the galvanized coating follows industry standards, as this can greatly affect the material's longevity.

Another factor to consider is the ease of installation. Galvanized wire mesh is lightweight and flexible, enabling quick and efficient setup, especially for large projects. Furthermore, its resistance to wear and tear reduces maintenance costs down the line, offering excellent value over time. Building a solid foundation with galvanized wire mesh can raise the overall quality and durability of your project, making it a wise investment.

Cost-Effectiveness of Galvanized Wire Mesh in Construction Projects

Galvanized wire mesh is increasingly becoming the preferred choice in construction projects due to its cost-effectiveness and durability. According to a report by MarketsandMarkets, the global market for wire mesh is projected to reach USD 23.4 billion by 2025, driven significantly by the rising demand for durable construction materials. Galvanized wire mesh provides a robust solution that doesn't just meet industry standards but often surpasses them. The galvanization process offers excellent resistance to corrosion, ensuring a longer lifespan compared to traditional materials, which often require costly replacements.

Tips: When considering galvanized wire mesh for your project, ensure that you evaluate the thickness and gauge appropriately for your specific application. Using appropriately sized wire mesh can enhance structural integrity while minimizing costs in the long run.

Furthermore, the initial investment in galvanized wire mesh can significantly save costs over time. Research indicates that projects utilizing galvanized materials can prevent up to 30% in maintenance costs due to their corrosion-resistant properties. This cost-effectiveness extends beyond material expenses; fewer repairs mean less downtime, which translates to increased efficiency and reduced labor costs.

Environmental Resistance: The Impact of Galvanization on Material Longevity

When considering materials for your next project, galvanized wire mesh stands out primarily due to its exceptional environmental resistance, a direct result of the galvanization process. In 2023, the U.S. hot-dip galvanized steel market was valued at approximately $16.88 billion, with projections indicating a rise to $20.12 billion by 2033. This significant market growth reflects the increasing recognition of galvanized steel's durability and resistance to corrosion, which are crucial for longevity in various applications, from construction to automotive parts.

One key advantage of galvanized wire mesh is its extensive lifespan. The galvanization process coats the steel with zinc, creating a barrier that protects against moisture and environmental factors. This is particularly important in regions with extreme weather conditions. As the global galvanized steel market is expected to grow from USD 241.87 billion in 2024 to USD 353.51 billion by 2030, it’s evident that this material is becoming a preferred choice among builders and manufacturers.

**Tips for Choosing Galvanized Wire Mesh:**

1. **Assess the Environment:** Consider the environmental conditions your project will face; if corrosion is a concern, galvanized wire mesh provides reliable protection.

2. **Evaluate Long-Term Costs:** While upfront costs may be higher, the long-term savings on maintenance and replacement due to the material's durability make galvanized wire mesh a cost-effective choice.

Why You Should Choose Galvanized Wire Mesh for Your Next Project - Environmental Resistance: The Impact of Galvanization on Material Longevity

| Property | Galvanized Wire Mesh | Non-Galvanized Wire Mesh |

|---|---|---|

| Corrosion Resistance | High | Low |

| Longevity (Years) | 20+ | 5-10 |

| Maintenance Required | Minimal | Frequent |

| Environmental Impact | Low | Moderate |

| UV Resistance | Excellent | Poor |

| Cost (per meter) | $1.50 | $1.00 |

Applications of Galvanized Wire Mesh Across Various Industries

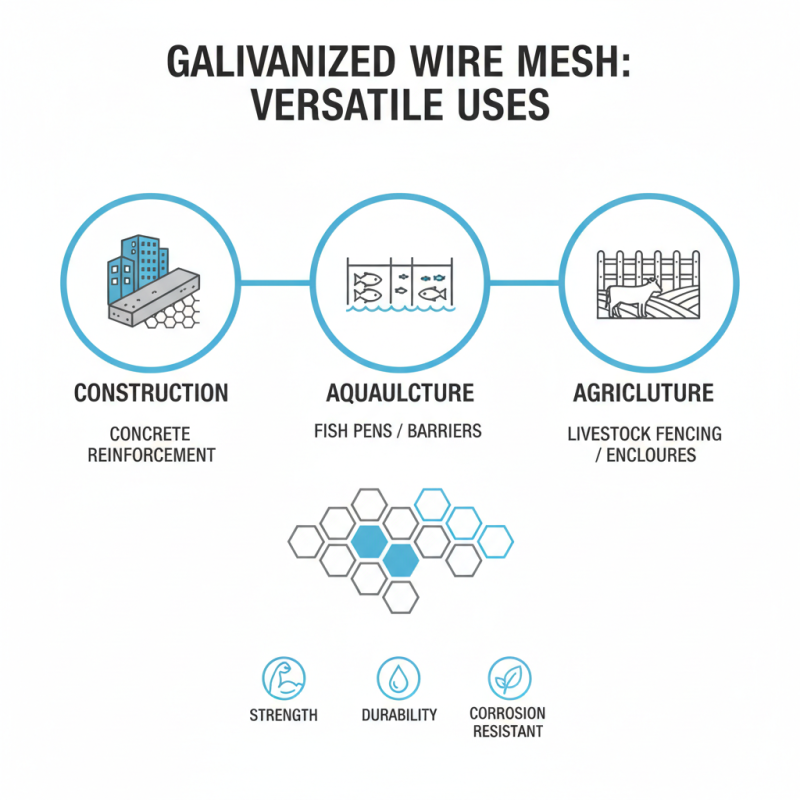

Galvanized wire mesh is a versatile material widely used across various industries due to its strength, durability, and resistance to corrosion. In construction, it provides essential support for concrete structures, acting as a reliable reinforcement element. Aquaculture also benefits from galvanized wire mesh, where it serves as an effective barrier for fish farming pens, ensuring the security and health of the aquatic life. In agriculture, it is frequently used for fencing, keeping livestock secure while allowing air and light to pass through.

When considering galvanized wire mesh for your project, keep in mind a few tips. First, always assess the gauge of the wire: thicker mesh generally offers better strength and durability. Second, consider the mesh size; a finer mesh may be necessary for smaller animals or plants to prevent escape or intrusion. Lastly, factor in the environment—if you are working in areas with high humidity or exposure to harsh chemicals, ensure that you select a mesh with an appropriate coating for added longevity.

In addition to its structural applications, galvanized wire mesh is also indispensable in landscaping. It can be used as a trellis for climbing plants or as a decorative feature in garden design. The mesh allows for creativity while ensuring structural support, making it a staple in many outdoor projects.

Comparative Analysis of Galvanized and Non-Galvanized Wire Mesh Options

When it comes to selecting wire mesh for construction and DIY projects, understanding the differences between galvanized and non-galvanized options is crucial. Galvanized wire mesh is coated with a layer of zinc, which provides an exceptional barrier against rust and corrosion. This makes it ideal for outdoor applications or environments that are exposed to moisture. On the other hand, non-galvanized wire mesh, while often cheaper, lacks this protective layer and is more susceptible to degradation over time, particularly in humid conditions.

In addition to durability, galvanized wire mesh offers better longevity and maintenance benefits. Projects that require structural integrity and long-term performance, such as fencing, roofing, or concrete reinforcement, greatly benefit from the enhanced lifespan of galvanized materials. Non-galvanized wire can be suitable for short-term or indoor applications but may require routine inspections and replacements due to its corrosive tendencies. Therefore, for projects demanding reliability and less frequent maintenance, choosing galvanized wire mesh proves to be a more sensible investment in the long run.

Comparison of Galvanized vs Non-Galvanized Wire Mesh Durability

The chart below illustrates the relative durability ratings of galvanized and non-galvanized wire mesh options over a period of time. Galvanized wire mesh generally offers superior resistance to rust and corrosion, making it a preferred choice for outdoor projects.

Related Posts

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

Revitalize Your Cleaning Routine: Discover the Power of Steel Brushes for Every Task

-

2025 How to Choose the Best MIG Wire for Optimal Welding Performance

-

What is a Stainless Steel Supplier and How to Choose the Right One

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Discover the Best Wire Brush Drill Attachments of 2025 for Efficient Cleaning and Rust Removal