Why Choose Stainless Steel Wire Mesh for Your Projects?

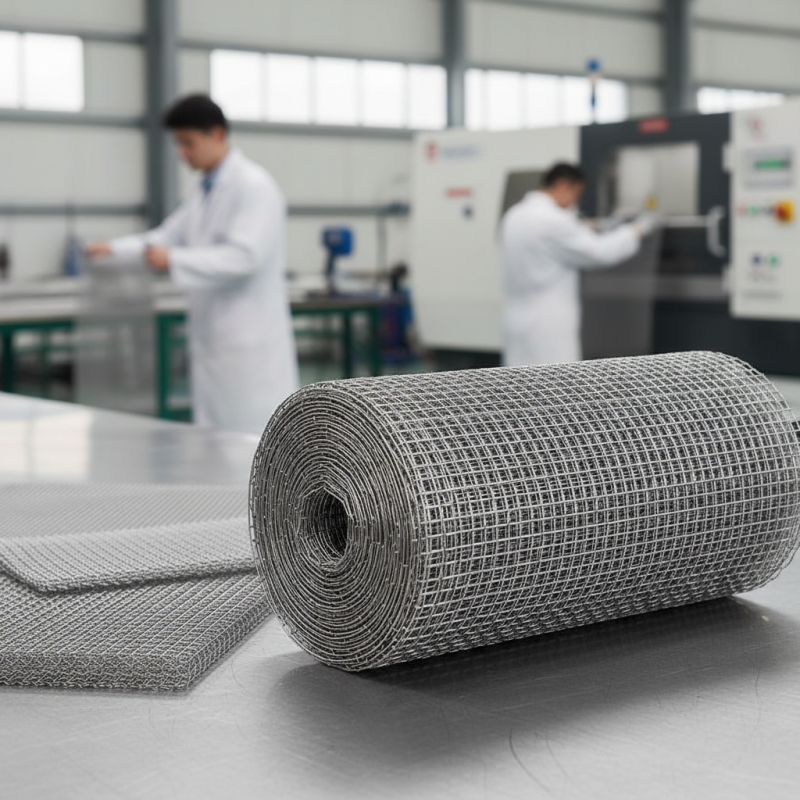

When considering materials for various projects, stainless steel wire mesh stands out as a top choice. Its durability, resistance to corrosion, and versatility make it suitable for a range of applications. According to a report by Global Industry Analysts, the global market for stainless steel wire mesh is expected to exceed $3 billion by 2026. These figures illustrate the growing demand and importance of using quality materials in diverse industries.

Expert David Smith, a well-respected specialist in materials science, emphasizes the practical benefits of stainless steel wire mesh. He states, "The reliability and strength of stainless steel wire mesh are unmatched in the construction and manufacturing sectors." This insight highlights the key reasons why it is favored in environments where durability is crucial.

Despite its advantages, choosing the right type of stainless steel wire mesh can be challenging. Variations in wire thickness, mesh size, and finish affect performance. It’s important to reflect on specific project needs and how different types of stainless steel wire mesh can achieve them. Understanding these nuances can lead to enhanced project outcomes.

Advantages of Stainless Steel Wire Mesh in Various Applications

Stainless steel wire mesh is widely recognized for its strength and versatility. Industries leverage it for various applications, including construction, filtration, and security. According to a market research report, the demand for stainless steel mesh is projected to grow by 5% annually. This trend is fueled by its durability and resistance to corrosion.

In construction, stainless steel wire mesh offers unmatched support and reinforcement. It withstands harsh environmental conditions, which reduces maintenance costs significantly. In filtration systems, it ensures high levels of purity. A recent study noted that stainless steel mesh filters can improve efficiency by nearly 30% compared to traditional materials. This efficiency can be critical in industries such as food processing and pharmaceuticals.

Security applications also benefit from stainless steel wire mesh. It provides a reliable barrier without sacrificing visibility. However, some users find it challenging to work with. The material can be stiff, and cutting it requires specialized tools. This might lead to inefficiencies if not properly managed. Nonetheless, its advantages often outweigh these challenges, making it an essential choice in many projects.

Why Choose Stainless Steel Wire Mesh for Your Projects? - Advantages of Stainless Steel Wire Mesh in Various Applications

| Application | Advantages | Material Grade | Typical Uses | Wire Diameter (mm) |

|---|---|---|---|---|

| Construction | Corrosion resistance, durability | 304 | Reinforcement, fencing | 2.0 - 5.0 |

| Food Industry | Non-reactive, easy to clean | 316 | Food processing, storage | 0.8 - 2.0 |

| Filtration | High strength, precise openings | 304 | Air, liquid filtration | 0.1 - 1.0 |

| Automotive | Durability, heat resistance | 430 | Exhaust systems, grills | 1.0 - 3.0 |

| Architecture | Aesthetic appeal, rust resistance | 304 | Decorative elements, partitions | 2.5 - 4.0 |

Comparison of Stainless Steel Wire Mesh with Other Materials

When comparing stainless steel wire mesh with other materials, its advantages become clear. Unlike plastic mesh, stainless steel won't deform under heat or pressure. It remains strong in extreme conditions. This durability is crucial for demanding environments. With plastic, the risk of breakage is much higher. This can lead to project failures, which can be costly.

Another notable comparison is with aluminum wire mesh. Aluminum is lighter, but it lacks the same corrosion resistance. In wet or humid conditions, aluminum can corrode quickly. Stainless steel, however, resists rust, making it ideal for outdoor projects. Using stainless steel may initially seem more expensive, but its longevity often justifies the cost. We need to rethink short-term savings versus long-term reliability.

However, stainless steel wire mesh does have its drawbacks. It can be heavier and more challenging to work with than lighter materials. Some projects may require frequent adjustments, potentially complicating installation. As you weigh the choices, consider your project's specific needs. Balancing strength and flexibility is essential in material selection.

Durability and Corrosion Resistance of Stainless Steel Wire Mesh

Stainless steel wire mesh is a popular choice for various projects, particularly due to its exceptional durability and corrosion resistance. Reports show that stainless steel can withstand harsh environments, making it ideal for construction and industrial applications. According to industry studies, stainless steel has a lifespan of over 50 years in most applications, significantly reducing maintenance costs.

Corrosion resistance is another critical advantage. The chromium content in stainless steel creates a protective layer against rust and deterioration. This property is particularly beneficial in coastal areas where salt and humidity can damage other materials. Research indicates that stainless steel, even in extreme conditions, maintains a 70% effectiveness in structural performance after years of exposure.

**Tip:** When selecting stainless steel wire mesh, consider the specific grade for your project. Different grades offer varying levels of corrosion resistance and strength.

It's important to note that while stainless steel is robust, it can still experience pitting corrosion. This occurs due to localized environmental factors. Regular inspections and maintenance of the mesh can help identify potential issues early.

**Tip:** Conduct routine checks on the mesh to spot any signs of wear or corrosion, especially in high-stress environments.

Applications of Stainless Steel Wire Mesh in Industrial and Commercial Settings

Stainless steel wire mesh is a versatile material in various industrial and commercial applications. It is widely used in construction, filtration, automotive, and manufacturing sectors. According to a report by MarketsandMarkets, the global stainless steel wire mesh market is expected to reach over $2 billion by 2025, demonstrating its growing significance.

In industrial settings, stainless steel wire mesh often functions as a barrier or filter. For instance, it is utilized in the food processing industry to ensure product safety. Mesh screens can prevent contaminants from entering food products during processing. Additionally, in the oil and gas sector, this wire mesh serves as a crucial component for filtration systems. Filters made from stainless steel wire mesh can withstand high pressures and temperatures.

Commercially, stainless steel wire mesh finds applications in architectural designs and security systems. It is often used in building facades, enhancing aesthetics while providing safety. However, not all installations are flawless. Issues like corrosion and wear over time can impact performance. Professionals must constantly evaluate conditions and adapt mesh to specific environments to ensure optimal use.

Maintenance Tips for Stainless Steel Wire Mesh Products

Stainless steel wire mesh is popular in many industries. It is strong, durable, and resistant to corrosion. However, proper maintenance is essential for maximizing its lifespan. Regular inspections can help identify wear and tear early. This is crucial for maintaining performance, as neglect can lead to costly replacements. Data from industry reports indicate that regular upkeep can extend the lifespan of stainless steel products by up to 50%.

Cleaning stainless steel wire mesh is straightforward. Use a mild detergent and warm water to clean it, avoiding harsh chemicals. A soft brush can help remove stubborn debris without scratching the surface. Despite its durability, stainless steel can still accumulate dirt and grime. Ignoring this can lead to corrosion over time. It's important to remember that regular maintenance can prevent this deterioration.

Storage is another important factor. If not used, store the wire mesh in a dry area to avoid moisture build-up. This can cause rust and other issues. While stainless steel is designed to withstand harsh conditions, it is not invincible. Be mindful that exposure to certain substances can weaken its integrity. Regularly review storage practices and assess environmental factors. These steps will ensure that your stainless steel wire mesh remains in optimal condition for years to come.

Why Choose Stainless Steel Wire Mesh for Your Projects?

Stainless steel wire mesh offers various advantages including high durability and corrosion resistance, making it an excellent choice for multiple applications. This chart illustrates the key benefits and their perceived effectiveness based on user feedback.