2026 How to Choose the Best Stainless Steel Screen for Your Needs?

Choosing the right stainless steel screen is crucial for various industries. With its durability and corrosion resistance, stainless steel screens are widely used in filtration and separation applications. According to a recent report from MarketsandMarkets, the global stainless steel screen market is expected to reach $2.5 billion by 2026, driven by growth in oil and gas, water treatment, and mining sectors.

Experts highlight the importance of selection. John Smith, a leading industry specialist, states, "Selecting the right stainless steel screen can significantly impact efficiency and product quality." Ensuring the right mesh size and material type is fundamental for optimal performance. Yet, choosing the wrong specifications can lead to operational inefficiencies and increased costs.

The decision-making process can be complex. Different projects have unique requirements, like temperature, pressure, and fluid type. Industrial operators often need to reflect on their specific needs. They must weigh multiple factors, which can be daunting in a crowded marketplace. A thoughtful approach can enhance the effectiveness of the chosen stainless steel screen, ultimately driving long-term success.

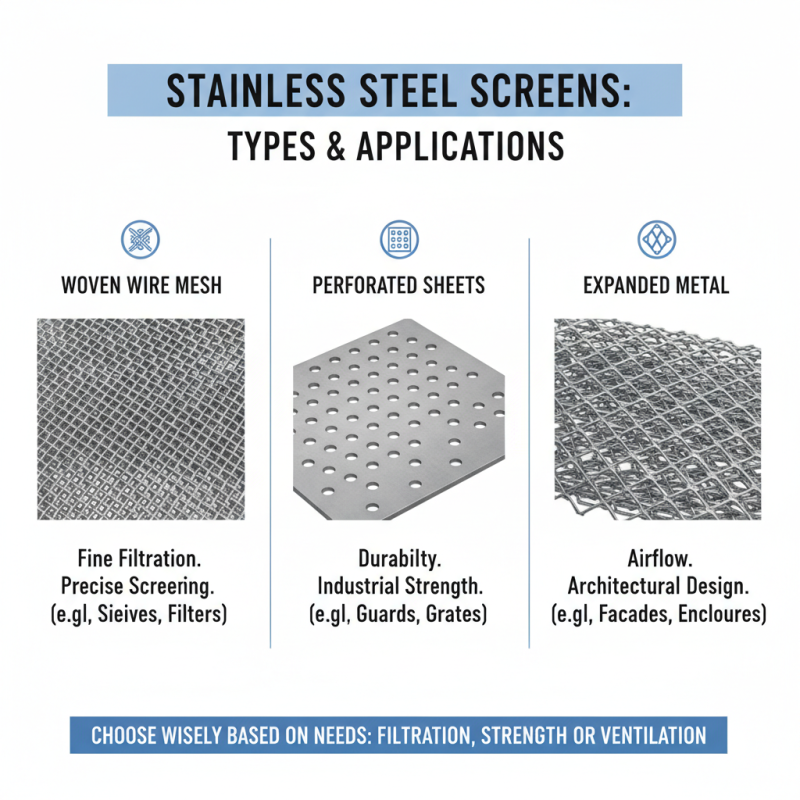

Understanding Stainless Steel Screen Types and Their Applications

When choosing a stainless steel screen, understanding its types and applications is crucial. There are several types available, including woven wire mesh, perforated sheets, and expanded metal. Woven wire mesh offers fine filtration. It is ideal for applications requiring precise screening. On the other hand, perforated sheets provide durability. They are often used in industrial settings where strength is essential. Expanded metal, with its unique design, allows for airflow. It is common in architectural applications.

Consider the specific needs of your project. If you require protection from small particles, woven wire mesh is preferable. For stronger structural integrity, perforated sheets might be the way to go. However, not every choice is perfect. Some users find that expanded metal can lack coverage for small debris. Others may struggle with the complex maintenance of woven wire. Reflecting on these factors can guide you. Ensure you choose what aligns best with your application, even if compromises are necessary.

Key Properties of Stainless Steel Screens: Strength, Corrosion Resistance, and Durability

When choosing a stainless steel screen, consider its key properties: strength, corrosion resistance, and durability. Strength is essential, especially for applications that require heavy-duty performance. Screens used in industrial settings may endure significant pressure. Selecting a product that can resist bending or breaking is critical for such uses.

Corrosion resistance plays a vital role in many environments. Stainless steel often withstands various chemicals and moisture. However, not all grades offer the same level of protection. Knowing your environment's specific conditions can help avoid costly replacements. It’s important to reflect on whether the chosen screen withstands the expected exposure levels.

Durability is another factor to consider. A durable screen lasts longer, reducing maintenance needs and costs. Yet, even the most robust materials can fail over time. Examine the wear and tear specific to your usage. Understanding these details is crucial for making an informed decision that meets your unique requirements.

Factors to Consider When Choosing Stainless Steel Screens for Specific Uses

Choosing the right stainless steel screen can be daunting. Different applications require specific features. For example, screens used in food processing need to prevent contamination while maintaining airflow. On the other hand, construction might prioritize strength and durability over aesthetics. It’s crucial to assess your specific needs.

Consider the mesh size. A finer mesh may be necessary for filtration applications. Larger meshes might be better for outdoor use, like fencing. If you are unsure, experimenting with different sizes can be helpful. Sometimes, a finer screen can prevent debris but can also clog more easily. Balance is key.

Tip: Always seek advice from experts. They can provide valuable insights tailored to your application. Assess the environment too. Will your screen face harsh weather? This can affect the material’s longevity. A less durable option might quickly fail under pressure. Testing samples can reveal unexpected weaknesses.

2026 How to Choose the Best Stainless Steel Screen for Your Needs?

Comparison of Stainless Steel Grades: Which is Best for Your Needs?

When selecting a stainless steel screen, understanding the different grades is crucial. Common grades include 304, 316, and 430. Each has unique properties that suit various applications.

Grade 304 is versatile and resistant to corrosion. It's ideal for kitchen use but may not withstand marine environments.

Grade 316 offers better protection against saltwater corrosion. This makes it suitable for coastal areas or maritime projects. However, it can be more expensive.

430, on the other hand, is a budget-friendly option. It's magnetic and less resistant to corrosion, making it fit for indoor applications.

Your choice ultimately depends on specific needs. Consider factors like environment, budget, and longevity. Sometimes, the best solution isn't straightforward. You may find that a lower grade works well in less demanding situations, while investing in a higher grade may lead to long-term savings in harsh conditions. Reflecting on these aspects can lead to a better decision.

Industry Trends: Innovations and Best Practices in Stainless Steel Screening Solutions

The stainless steel screening industry has seen notable innovations lately. Advances in materials and design have led to more durable and efficient screens. These improvements allow for enhanced filtration capabilities. Many manufacturers are prioritizing resistance to corrosion and abrasion.

Emerging technologies are making screens more versatile. New designs focus on easy installation and maintenance. Some recent screens come with self-cleaning features. These innovations save time and reduce manual labor. However, the adoption of these solutions often requires upfront investment. Some buyers hesitate to embrace these changes.

Sustainability remains a critical concern. Manufacturers are exploring eco-friendly materials and production processes. There’s a growing demand for screens that reduce environmental impact. Yet, not all companies are equipped to meet this challenge. Evaluating long-term benefits over immediate costs is essential. Balancing efficiency and sustainability could lead to better choices.

2026 How to Choose the Best Stainless Steel Screen for Your Needs?

| Screen Type | Mesh Size (Microns) | Durability Rating | Typical Applications | Cost per Square Foot |

|---|---|---|---|---|

| Woven Wire Screen | 20-500 | High | Food Processing, Water Filtration | $15 - $30 |

| Perforated Metal Screen | Varies (1mm - 10mm Holes) | Medium | Mining, Construction | $10 - $25 |

| Expanded Metal Screen | Large (1/4" - 2") | Low | Security Fencing, Ventilation | $5 - $15 |

| welded Wire Screen | 15-100 | Very High | Construction, Agriculture | $20 - $40 |

| Strainer Screen | 50-300 | High | Oil & Gas, Chemical Processing | $15 - $35 |

Related Posts

-

Why You Should Choose Wire Cloth for Your Industrial Filter Needs

-

Top 10 Best Stainless Steel Wire Mesh Options for Your Projects?

-

Discover the Best Wire Brush Drill Attachments of 2025 for Efficient Cleaning and Rust Removal

-

Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

-

2025 How to Choose the Best Stainless Steel Mesh Screen for Your Needs

-

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects