Why You Should Choose Wire Cloth for Your Industrial Filter Needs

In the realm of industrial filtration, the choice of materials plays a pivotal role in determining the efficacy and durability of filters. Wire cloth has emerged as a standout choice for various filtration applications, thanks to its unparalleled strength, versatility, and resistance to wear and tear. As industry expert Dr. Sarah Thompson, a leading figure in filtration technology, aptly puts it: "Wire cloth is not just a material; it is the backbone of efficient filtration systems, providing optimal performance and longevity."

Selecting wire cloth as a filtration medium not only ensures superior particle retention but also enhances operational efficiency, reducing maintenance costs in the long run. With its customizable design options, wire cloth can be tailored to meet specific filtration requirements, making it ideal for diverse industries ranging from food processing to chemical manufacturing. This adaptability, coupled with its superior mechanical properties, underscores why wire cloth should be at the forefront of any industrial filter selection process.

With the growing need for sustainable and efficient filtration solutions, understanding the advantages of wire cloth becomes essential. As we delve deeper into its benefits, it becomes clear that choosing wire cloth for your industrial filter needs is not just a decision; it’s a strategic move towards enhanced performance and reliability.

Benefits of Wire Cloth in Industrial Filtration Applications

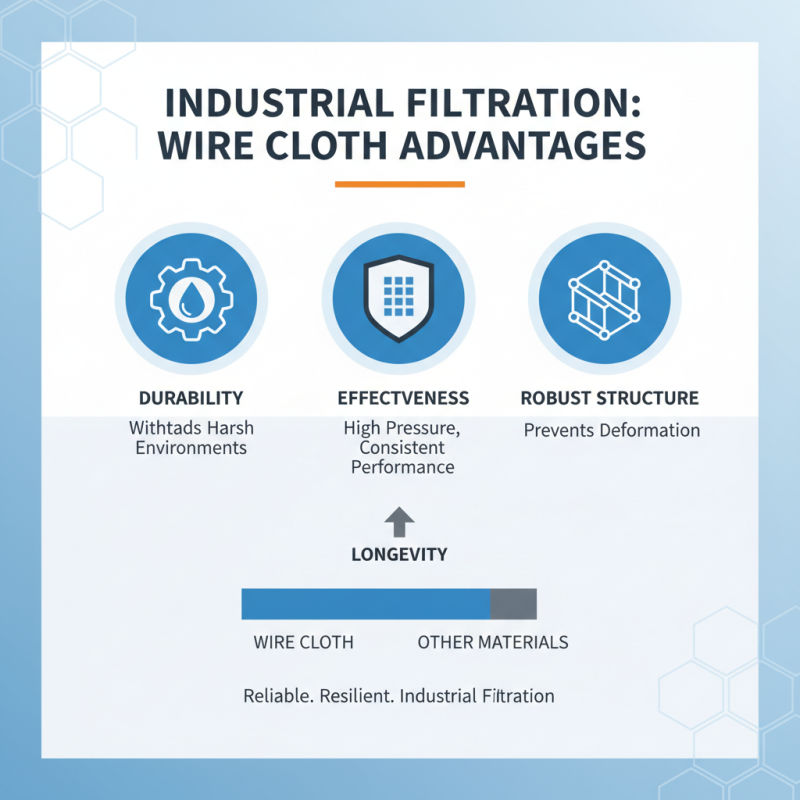

When it comes to industrial filtration applications, wire cloth stands out for its durability and effectiveness. Unlike other filtering materials, wire cloth is designed to withstand harsh environments and high pressures, making it an excellent choice for a variety of industries. Its robust structure prevents deformation and maintains its filtration integrity over time, ensuring consistent performance.

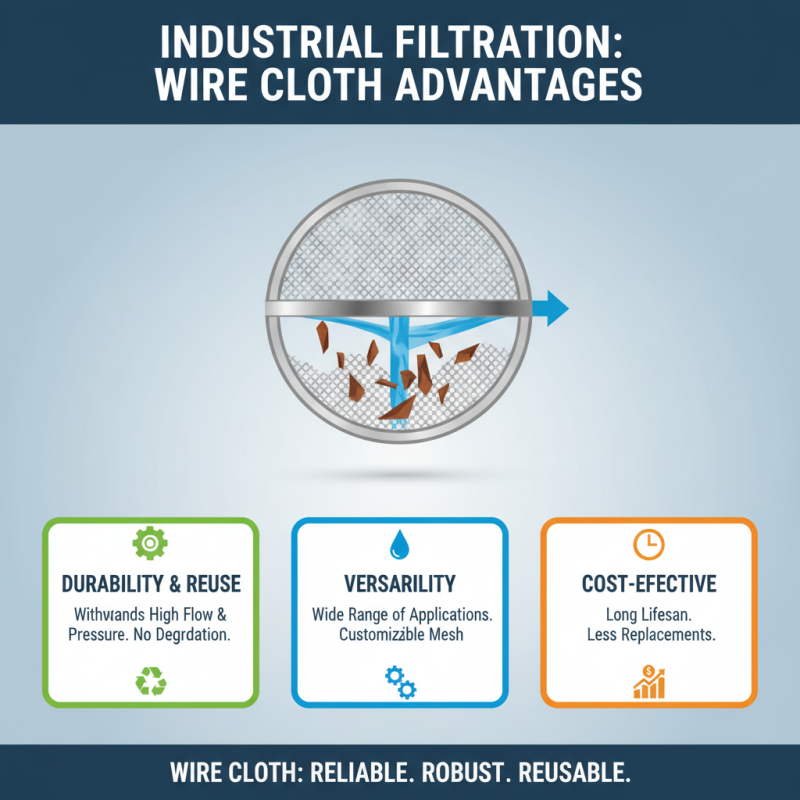

One of the key benefits of wire cloth is its versatility. Available in various mesh sizes and materials, it can be tailored to meet specific filtration requirements. This adaptability allows businesses to optimize their filtration systems for different processes, whether they require fine filtration or coarse screening. Additionally, wire cloth is reusable and easy to clean, reducing long-term operational costs and environmental impact.

Tips: When choosing wire cloth for your filtration needs, consider factors such as the wire gauge, mesh size, and the type of material best suited for the substances being filtered. Always assess the chemical compatibility of the wire cloth with the liquids or gases to be filtered to ensure long-lasting performance. Regular maintenance and cleaning can also extend the lifespan of your wire cloth, helping you achieve better filtration results efficiently.

Types of Wire Cloth Materials Suitable for Industrial Filters

When it comes to selecting the right materials for industrial filters,

wire cloth stands out for its durability and versatility. There are various types of wire cloth materials available, each with unique characteristics that cater to different filtering needs. For instance,

stainless steel wire cloth is a popular choice due to its high resistance to corrosion and ability to withstand high temperatures. This makes it ideal for industries dealing with harsh environments, such as

chemical manufacturing or

food processing.

Another excellent option is

polyester wire cloth, which is lightweight and resistant to a range of chemicals, making it suitable for applications that involve mild chemicals or moisture. Its flexibility allows for easier installation and maintenance. Additionally,

brass wire cloth offers a balance between cost-effectiveness and performance, with suitable applications in lower-pressure environments, such as in the

automotive and

electronics industries.

Ultimately, the choice of wire cloth material depends on the specific requirements of the industrial application, including factors such as the type of contaminants to be filtered, the operating conditions, and the longevity needed from the filter. Each material brings unique advantages that can greatly enhance the efficiency and effectiveness of the filtration process.

Factors to Consider When Selecting Wire Cloth for Filtration

When selecting wire cloth for your industrial filtration needs, several factors should be considered to ensure optimal performance. First and foremost, assess the material type; stainless steel, for instance, is known for its durability and resistance to corrosion, making it ideal for demanding environments. Additionally, the mesh size plays a crucial role in determining what particulates will be filtered out. A finer mesh can trap smaller particles, while a coarser mesh allows for greater flow rates.

**Tips:** Consider the working environment of your filter. High temperatures or exposure to harsh chemicals may necessitate specialized wire cloth materials. Also, keep in mind the ease of cleaning and maintenance, as some wire cloths may require more frequent upkeep than others.

While operational needs are essential, don't overlook the importance of the support structure. A well-designed frame can enhance the efficiency of the wire cloth by providing stability and reducing the chances of sagging or tearing during use. Proper framing ensures that the wire cloth maintains its shape and function over time, thus extending its service life.

**Tips:** Always consider the weight and strength of your wire cloth in relation to its intended application. Heavy-duty options may be required for high-pressure applications, while lighter options can be sufficient for less demanding environments.

Why You Should Choose Wire Cloth for Your Industrial Filter Needs - Factors to Consider When Selecting Wire Cloth for Filtration

| Factor | Description | Material | Applications |

|---|---|---|---|

| Mesh Size | Refers to the number of openings per inch. A higher mesh size means finer filtration. | Stainless Steel | Oil filtration, beverage processing |

| Wire Diameter | Influences the strength and flow rate of the filtration. | Monel | Chemical processing, marine applications |

| Opening Shape | Can be square or rectangular, affecting filtration properties. | Copper | Pharmaceuticals, food processing |

| Corrosion Resistance | Essential for longevity in harsh environments. | Aluminum | Wastewater treatment, desalination |

| Temperature Tolerance | Ability to maintain structural integrity at high temperatures. | Steel | Gas filtration, engine cooling systems |

Comparison of Wire Cloth and Alternative Filtration Methods

When evaluating filtration options for industrial applications, wire cloth stands out when compared to alternative methods such as paper filters, membrane filters, or synthetic filters. Wire cloth offers a combination of durability and versatility that many alternatives cannot match. Unlike paper filters, which can clog quickly and need frequent replacement, wire cloth allows for continuous use without the risk of degradation. Its robust construction means it can withstand high flow rates and variable pressure levels, making it ideal for demanding environments.

In contrast to membrane filters, which often require precise operating conditions and can be prone to fouling, wire cloth provides a more forgiving filtration solution. It maintains its structural integrity even under challenging conditions, reducing the likelihood of operational downtime. Furthermore, synthetic filters, while effective, can sometimes introduce issues related to chemical compatibility and environmental impact. Wire cloth, being made from metals, is not only long-lasting but also recyclable, making it a more sustainable choice for industries looking to improve their ecological footprint. Thus, for those seeking an effective, reliable, and environmentally-friendly filtration method, wire cloth presents itself as a superior option.

Maintenance and Longevity of Wire Cloth Filters in Industry

Wire cloth filters are increasingly favored in industrial settings due to their outstanding durability and ease of maintenance. The design of wire cloth allows for a high flow rate while effectively capturing particulates, making them an ideal choice for various applications. One of the primary advantages of wire cloth filters is their longevity. Unlike traditional filter media that may degrade or clog quickly, wire cloth can withstand harsh environments and extended use, ultimately reducing the need for frequent replacements.

Maintenance of wire cloth filters is straightforward. Regular cleaning can prolong their lifespan significantly, ensuring efficient operation without the need for costly replacements. Unlike disposable filters that can produce waste and require special disposal procedures, wire cloth filters can often be rinsed or backwashed, making them not only economical but also environmentally friendly. This ease of maintenance contributes to less downtime in industrial processes, allowing for continuous operation and improved productivity over time. Additionally, wire cloth's robustness means it can be used in various applications, from water treatment to food processing, making it a versatile solution for industrial filtration needs.

Related Posts

-

Exploring the Benefits of Steel Mesh: The Ultimate Guide for Builders and DIY Enthusiasts

-

Top Wire Brush Types to Choose for Effective Cleaning in 2025

-

Discovering the Versatility and Durability of 304 Stainless Steel in Modern Applications

-

The Versatility of Stainless Steel Cable: Applications, Benefits, and Innovations

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Why Choosing the Right Stainless Steel Manufacturers Matters for Your Projects