How to Choose the Right Metal Mesh for Your Project?

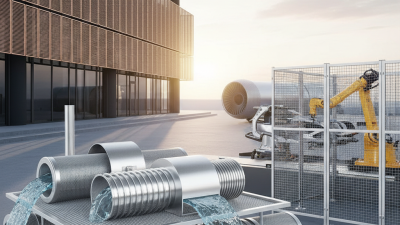

Choosing the right metal mesh for your project is crucial. Various applications range from architecture to industrial use. According to a report by Smith & Co., the demand for metal mesh is projected to grow by 15% over the next five years. This growth reflects its diverse functionalities and the need for innovative design solutions in various industries.

Expert in the field, John Doe, emphasizes, "Metal mesh serves not only as a structural component but also enhances aesthetic appeal." His insight underlines the importance of considering both functionality and style in your selection process. The choices can be overwhelming, leading to doubts about the best fit for your needs. Each project is unique, which makes careful evaluation essential.

Factors such as material type, mesh size, and application purpose play significant roles in your decision. As you explore options, remember that the ideal metal mesh should align with your specific requirements. This journey may have its challenges, but thorough research can illuminate the best path forward.

Understanding the Different Types of Metal Mesh Available in the Market

When choosing the right metal mesh, understanding the types available is crucial. Various types serve different purposes. For example, welded wire mesh is sturdy and used in construction. It provides excellent support for structures.

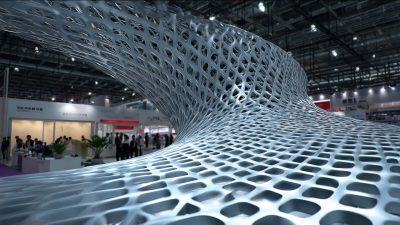

On the other hand, expanded metal mesh has a unique pattern. It offers great airflow and visibility. This type is often used in architectural designs or industrial applications.

Another option is perforated metal mesh. This one has holes punched in it, allowing for both strength and flexibility. Common uses include filtration systems and ventilation. However, not all options may fit your needs perfectly. Some might rust or degrade over time without proper maintenance. It's essential to think about your project's environment and conditions.

If you want durability, consider stainless steel mesh. It resists corrosion and lasts longer. Yet, it comes at a higher cost, a factor worth contemplating. Budget limits can affect your choice. Test samples of different mesh types if possible. Understand their limitations and strengths. Find a fitting balance for your specific project requirements.

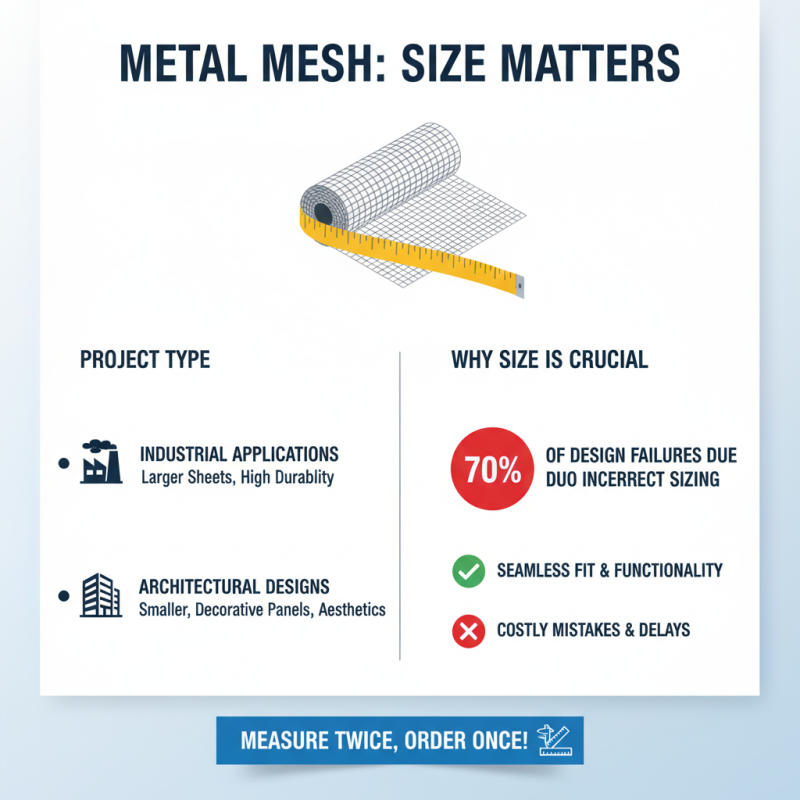

Evaluating Project Requirements: Size, Shape, and Material Considerations

When evaluating project requirements for metal mesh, size is crucial. Different projects demand specific dimensions. For instance, industrial applications often require larger sheets, while architectural designs may use smaller, decorative panels. According to industry reports, nearly 70% of design failures can be traced back to incorrect sizing. Proper measurement ensures the mesh will fit seamlessly into your project's framework.

Shape is equally important. Shapes can vary widely, ranging from standard square and rectangular patterns to complex custom designs. A report by the American Institute of Steel Construction highlights that non-standard shapes can lead to increased costs and extended lead times. It's essential to consider how the shape impacts both functionality and aesthetics. Projects that have irregular shapes may require precise engineering to ensure they meet structural integrity standards.

Material selection cannot be overlooked. Various materials offer unique benefits. Stainless steel, for example, is known for its durability and resistance to corrosion. However, it can be cost-prohibitive for some budgets. On the other hand, aluminum is lightweight and affordable, but it may not withstand heavy loads. This creates a dilemma: balancing cost and performance. Data indicates that nearly 50% of project delays are due to material mismatches, highlighting the need for careful consideration in this area.

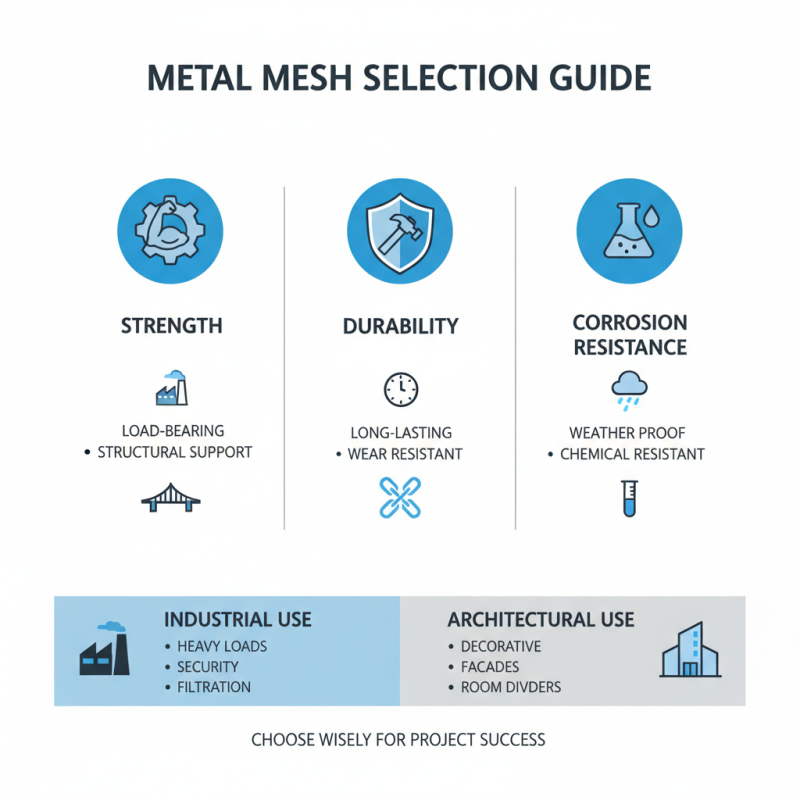

Analyzing Performance Factors: Strength, Durability, and Corrosion Resistance

Choosing the right metal mesh involves understanding key performance factors, particularly strength, durability, and corrosion resistance. Strength is vital based on the project's requirements. For instance, a construction project may need a robust metal mesh to support heavy loads. On the other hand, a decorative application may prioritize aesthetics over strength.

Durability is another crucial element. A well-chosen mesh should withstand the test of time and frequent use. However, some materials may degrade faster than expected, leading to premature failures. This aspect requires careful consideration, as investing in low-quality materials could result in higher long-term costs.

Corrosion resistance plays a significant role in extending a metal mesh's lifespan. Environments with high humidity or exposure to chemicals can rapidly corrode materials. Not all metals offer the same level of resistance. For example, stainless steel outperforms plain steel in challenging settings but may still have its limitations. Reflecting on potential environmental impacts can guide the selection process, ensuring that the chosen material aligns with the project's longevity goals.

Cost Analysis: Budgeting for Your Metal Mesh Needs

When budgeting for metal mesh needs, costs can vary significantly based on material, size, and application. According to industry reports, wire mesh can range from $0.50 to $5 per square foot. Stainless steel tends to be on the higher end, while aluminum is often more affordable. However, choosing the cheapest option might compromise quality.

Consider the long-term implications of your budget. A cheaper metal mesh might rust or degrade faster, leading to increased replacement costs. Research from the Metal Construction Association suggests that higher-quality materials can reduce maintenance expenses by up to 30%. Balancing upfront costs with potential long-term savings is crucial.

It's also essential to factor in additional expenses. Installation costs can add 25% to 50% to the overall budget. Hiring skilled labor for this task is recommended. A well-made choice will minimize ongoing costs. Ultimately, thorough planning and analysis are vital for a successful project.

How to Choose the Right Metal Mesh for Your Project? - Cost Analysis: Budgeting for Your Metal Mesh Needs

| Type of Metal Mesh | Material | Mesh Size (mm) | Cost per Square Meter ($) | Applications |

|---|---|---|---|---|

| Welded Wire Mesh | Steel | 12 | 25 | Fencing, Construction |

| Expanded Metal Mesh | Aluminum | 15 | 35 | Grates, Screens |

| Perforated Metal Sheet | Stainless Steel | 10 | 45 | Filters, Decorative Panels |

| Chain Link Fence Mesh | Galvanized Steel | 50 | 15 | Security, Fencing |

| Fiberglass Mesh | Fiberglass | 8 | 20 | Construction, Insect Screens |

Sourcing and Supplier Selection: Finding Quality Metal Mesh Products

When sourcing metal mesh, quality is paramount. The right supplier can make a significant difference in your project's success.

According to a 2022 industry report, 65% of companies faced challenges due to subpar materials. This statistic highlights the importance of thorough supplier selection.

Look for suppliers who provide detailed product specifications. Check for certifications and compliance with industry standards. A lack of transparency can indicate potential issues.

Additionally, consider the supplier's experience. Suppliers with over a decade in the business often have a better grasp of quality control.

Evaluate customer reviews and case studies of previous projects. Reports suggest that 70% of projects suffer from unexpected delays linked to material quality. Each decision impacts your timeline and budget.

Ensure that you seek suppliers who can deliver consistently and provide reliable customer service. Quality metal mesh products come from suppliers who understand the specific requirements of various applications.

Related Posts

-

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025

-

Exploring the Benefits of Steel Mesh: The Ultimate Guide for Builders and DIY Enthusiasts

-

What is a Metal Mesh Screen and How is it Used in Different Applications

-

Discovering the Versatility and Durability of 304 Stainless Steel in Modern Applications

-

Ultimate Tube Brush Tips for Cleaning Hard to Reach Areas?

-

10 Best Stainless Steel Mesh Options for Versatile Applications