How to Choose the Right MIG Wire for Your Welding Projects

Choosing the right MIG wire for your welding projects is crucial for achieving optimal performance and quality in your welds. According to the American Welding Society, the proper selection of filler materials can significantly affect the strength and durability of welds, with wrong choices leading to defects and increased rework costs, which can be as high as 30% in some industries. This emphasizes the importance of understanding the different types of MIG wire available, such as ER70S-6 or ER308L, and their specific applications.

In addition, industry trends indicate a growing demand for specialized MIG wires that cater to various materials, including stainless steel, aluminum, and high-strength steels, reflecting the increasingly complex nature of modern manufacturing. A report by MarketsandMarkets forecasts the global welding consumables market, which includes MIG wire, to reach $19.9 billion by 2025, highlighting the critical role that these materials play in sectors ranging from automotive to construction.

Therefore, knowing how to choose the right MIG wire not only ensures better weld quality but also aligns with the evolving demands of the industry, making this decision a vital aspect of any welding project.

Understanding MIG Wire Types and Their Applications

When selecting the right MIG wire for your welding projects, understanding the various types and their specific applications is crucial. MIG wires come in several types, primarily categorized by the material they are made from, including solid steel wires, copper-coated wires, and aluminum wires. According to recent market analysis, the solid welding wires sector is projected to witness substantial growth, driven by increased demand in sectors such as automotive, construction, and manufacturing. Each wire type serves different purposes; for instance, solid steel wires are excellent for general fabrication, while aluminum wires are preferred for lightweight applications.

Tips: Always consider the material of the base metal you are welding. Using the appropriate MIG wire not only enhances the quality of the weld but also ensures long-lasting joints that can withstand various stresses. For thicker materials, a larger diameter wire may be needed to provide adequate penetration.

Moreover, non-destructive testing (NDT) plays an essential role in maintaining the integrity of welds, helping detect issues that could lead to failures. The implementation of advanced technologies, like the Heterogeneous Attention Multi-Scale Network (HAMS-Net) for weld seam classification, is transforming the industry, ensuring better quality control and consistency in welding practices. Such innovations can lead to significant improvements in safety and operational efficiency on welding projects.

Factors to Consider When Selecting MIG Wire Diameter

When selecting the diameter of MIG wire for welding projects, several key factors must be considered to ensure optimal weld quality and performance. One important aspect is the compatibility of the wire diameter with the material thickness being welded. Generally, larger diameters like 0.045 inches work best for thicker materials, enabling a higher deposition rate and stronger welds. Conversely, for thinner materials, a smaller diameter, such as 0.030 inches, can provide better control and reduce the risk of burn-through, which is critical in applications involving advanced high-strength steels.

Additionally, the choice of wire diameter influences the overall welding throughput—a crucial factor for profitability in welding operations. Research indicates that adjusting wire diameter can enhance welding speed without compromising quality, allowing welders to increase productivity. According to a study on resistance spot welding, factors such as electrode force and current type significantly affect weld quality. By understanding the interplay between wire diameter and these mechanics, fabricators can optimize their processes. Thus, understanding these parameters can lead to improved weld integrity and operational efficiency in various welding applications, including structural steel fabrication and ship construction.

Choosing the Right Filler Material for Your Welding Needs

When selecting the right filler material for welding, it is essential to consider the specific requirements of your welding project. The choice of filler metal can significantly affect the quality and durability of the weld, especially in high-demand applications such as those involving ASTM A335 grade P11 Cr-Mo alloyed steels. Recent advancements have led to the introduction of modern filler metal formulations that enhance the reliability and performance of welds in high-temperature environments.

In addition to understanding the metallurgical properties of the filler material, welders should also consider factors such as compatibility with the base materials, the welding process being employed, and the intended service conditions of the weld. As modern projects increasingly involve dissimilar materials and complex geometries, choosing a filler that can withstand elevated temperatures and pressures is crucial. Therefore, staying updated on the latest product offerings and technological advancements in filler metals is vital for achieving optimal results in any welding application.

How to Choose the Right MIG Wire for Your Welding Projects - Choosing the Right Filler Material for Your Welding Needs

| Wire Type | Material | Diameter (inches) | Recommended Applications | Suggested Shielding Gas |

|---|---|---|---|---|

| ER70S-6 | Mild Steel | 0.030 | General purpose fabrication | C25 (75% Ar, 25% CO2) |

| ER308L | Stainless Steel | 0.035 | Welding thin section stainless | 100% Argon |

| ER70S-3 | Mild Steel | 0.045 | Heavy duty applications | C25 (75% Ar, 25% CO2) |

| ER5356 | Aluminum | 0.030 | High strength aluminum structures | 100% Argon |

| ER70S-2 | Mild Steel | 0.035 | General purpose welding | C25 (75% Ar, 25% CO2) |

Evaluating Wire Coating and Its Impact on Welding Quality

When selecting MIG wire for your welding projects, the type of coating on the wire plays a crucial role in determining the quality of the weld. Wire coatings such as copper or zinc can significantly influence the welding process by affecting the arc stability and reducing spatter. According to a report by the American Welding Society, using a copper-coated wire can enhance electrical conductivity by up to 20%, leading to improved arc performance. This is particularly important in high-amp applications where stable arcs yield better penetration and less distortion.

Tip: Always choose a wire coating that complements your specific welding environment to minimize contamination. For outdoor or windy conditions, a more robust coating might be necessary to maintain a stable arc despite environmental challenges.

The wire’s coating not only impacts the weld quality but also affects the wire’s feedability through the welder. A poorly coated wire may lead to inconsistent feeding and increased downtime during welding operations. Industry studies have shown that 30% of welding failures are linked to wire feed issues, emphasizing the importance of selecting the right coated wire for seamless welding.

Tip: Test different wire types and coatings on scrap material to see which yields the best results for your specific project before proceeding with actual work.

Choosing the Right MIG Wire for Your Welding Projects

Tips for Matching MIG Wire with Your Welding Equipment

When it comes to selecting the right MIG wire for your welding projects, pairing the wire with your welding equipment is crucial for achieving optimal results. According to a report by the American Welding Society, nearly 75% of weld quality issues stem from incompatibilities between the wire and the welding machine. Therefore, understanding the specifications of both your MIG welder and the wire you choose is essential.

For example, if you're using a MIG welder that's designed for mild steel, you should opt for ER70S-6 wire, which is widely recognized for its efficiency in providing excellent welds. This type of wire is suitable for various welding positions and can handle contaminants, ensuring stronger welds. Additionally, ensure that the diameter of the wire corresponds to your welder's capabilities; a 0.030" diameter wire is typically recommended for machines rated at 130 to 180 amps. Using the right gas, such as a mixture of argon and carbon dioxide, can also enhance performance and prevent issues like porosity, ensuring the integrity of your welds.

Related Posts

-

2025 How to Choose the Best MIG Wire for Optimal Welding Performance

-

Why Stainless Steel Mesh Screens Are Essential for Your Home and Industry Needs

-

Discovering the Versatility of 316 Stainless Steel: Applications You Never Knew About

-

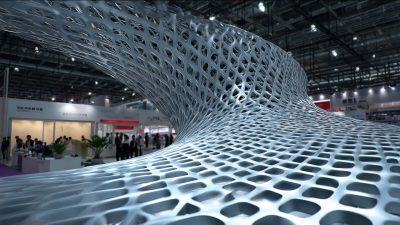

Innovative Trends and Market Insights for Welded Wire Mesh at the 2025 China Import and Export Fair

-

The Versatility of Stainless Steel Cable: Applications, Benefits, and Innovations

-

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025