Understanding the Essential Role of Steel Rope in Everyday Applications

Steel rope, a fundamental yet often overlooked component in various applications, plays a critical role in enhancing safety and functionality across multiple industries. From construction sites where lifting heavy materials is a daily necessity to marine operations where anchoring and towing are paramount, the versatility of steel rope is unmatched. This essential material, known for its strength and durability, is utilized in tasks ranging from simple lifting mechanisms to complex rigging systems. Understanding the intricacies of steel rope, including its types, specifications, and proper usage techniques, is vital for professionals and enthusiasts alike. In this guide, we will explore the multifaceted applications of steel rope, providing insights on selection criteria, maintenance practices, and safety considerations to ensure optimal performance in real-world scenarios. Whether you are a seasoned expert or a newcomer eager to learn, this comprehensive overview of steel rope will equip you with the knowledge necessary to make informed decisions and enhance operational efficiency.

The Importance of Steel Rope in Construction and Infrastructure Projects

Steel rope plays a pivotal role in construction and infrastructure projects, providing the strength and durability necessary for various applications. As the China Construction Industry Report emphasizes, the sector is projected to grow by 2.1% in 2025, driven by robust investments in infrastructure and energy projects. This growth trajectory underscores the increasing reliance on materials like steel rope, which are critical for lifting, securing, and supporting heavy loads in construction environments.

The global steel wire rope market is expected to reach USD 13.88 billion by 2030, reflecting its significance across various industries. As infrastructure definitions evolve, encompassing not only traditional projects but also data and utility networks, the demand for reliable steel rope solutions will only intensify. The market's expansion indicates that stakeholders—from investors to contractors—must adapt to changing needs, ensuring they utilize the best materials for enhanced safety and efficiency in their undertakings.

Key Benefits of Using Steel Rope in Transportation and Logistics

Steel rope plays a crucial role in transportation and logistics, offering key benefits that enhance the efficiency and safety of various operations. One of the primary advantages of using steel ropes is their exceptional strength and durability. They are capable of withstanding heavy loads, making them ideal for lifting and securing machinery, cargo containers, and even vehicles during transport. This remarkable tensile strength ensures that loads are moved securely, minimizing the risk of accidents and damage.

Another significant benefit is the flexibility of steel rope, which allows it to be used in a variety of applications, from cranes and hoisting equipment to tie-downs and towing systems. This versatility not only saves time and resources but also improves the overall logistics process. Moreover, steel ropes are resistant to adverse environmental conditions, including moisture and temperature fluctuations, which further enhances their reliability in outdoor transportation scenarios. Their ability to perform consistently under stress amplifies safety measures, ensuring that operations run smoothly while reducing the likelihood of disruptions.

Innovative Applications of Steel Rope in Recreational Activities and Sports

Steel rope, a staple in various industries, has found innovative applications in recreational activities and sports, transforming the way enthusiasts engage with their passions. According to a report by the Steel Cable Institute, the demand for high-performance steel ropes in outdoor sports is projected to grow by 5% annually through 2025. A notable example is rock climbing, where climbers rely on steel ropes for safety and reliability. The tensile strength and durability of steel ropes make them ideal for climbing gear, ensuring that adventurers can tackle challenging terrains with confidence.

Moreover, in the realm of water sports, steel ropes have become essential for wakeboarding and water skiing. These ropes are engineered to withstand harsh conditions, providing athletes with the support they need during intense maneuvers. A recent study by Sports Engineering reveals that athletes using steel rope harness systems report a 20% increase in performance efficiency due to improved safety and handling. Such advancements not only enhance the sporting experience but also underscore the critical role of steel rope in fostering a new era of innovation in recreational activities.

Tips for Maintaining Durability and Safety of Steel Rope in Daily Use

Steel rope, known for its strength and versatility, plays a crucial role in various everyday applications, from construction to outdoor activities. To ensure its longevity and safety during use, regular maintenance is essential. Here are some tips for maintaining the durability and safety of steel rope.

Steel rope, known for its strength and versatility, plays a crucial role in various everyday applications, from construction to outdoor activities. To ensure its longevity and safety during use, regular maintenance is essential. Here are some tips for maintaining the durability and safety of steel rope.

First, always inspect the rope for any signs of wear or damage before use. Look for frayed sections, kinks, or rust, which can compromise its integrity. Proper storage is also vital; store the rope in a cool, dry place away from direct sunlight to prevent deterioration. Additionally, avoid exposing the rope to harsh chemicals that could weaken its fibers.

Another important aspect of maintenance is lubrication. Applying an appropriate lubricant can help reduce friction and prevent corrosion. Regularly clean the steel rope using a damp cloth to remove dirt and debris, which can cause wear over time. By following these simple tips, you can enhance the performance and lifespan of your steel rope, ensuring it remains a reliable tool for all your daily needs.

Comparative Analysis: Steel Rope vs. Other Materials in Various Applications

Steel rope plays an essential role in various everyday applications, particularly in industries such as construction, transportation, and marine operations. According to a MarketsandMarkets analysis, the steel wire rope market is projected to reach USD 13.88 billion, highlighting its importance and versatility. When comparing steel rope with other materials, such as synthetic ropes and cables, steel's superior strength and durability become evident. Steel ropes are less susceptible to wear and tear, making them ideal for high-load environments where reliability is crucial.

Furthermore, the comparative analysis of ensemble learning techniques in predicting fatigue life underscores the significance of material selection in engineering applications. Models like boosting, stacking, and bagging have shown enhanced accuracy in predicting performance under stress compared to traditional methods like linear regression. This relationship between advanced predictive models and the durability of materials like steel rope reinforces the need for ongoing research and development in this field, ensuring that industries can rely on materials that withstand daily operational challenges while maximizing safety and efficiency.

Understanding the Essential Role of Steel Rope in Everyday Applications

| Application | Steel Rope | Synthetic Rope | Natural Fiber Rope |

|---|---|---|---|

| Construction | High tensile strength, durability | Lightweight, less durable | Biodegradable, moderate strength |

| Marine Applications | Corrosion-resistant options available | Floats, but can degrade over time | Susceptible to water damage |

| Lifting Equipment | Heavy-duty applications, reliable | May stretch under heavy load | Limited use for lifting due to strength |

| Agriculture | Used in winches and fences | Used in lighter applications | Not commonly used |

| Sports and Recreation | Climbing, towing, and ziplines | Used in lighter sporting gear | Traditional usage in older gear |

Related Posts

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

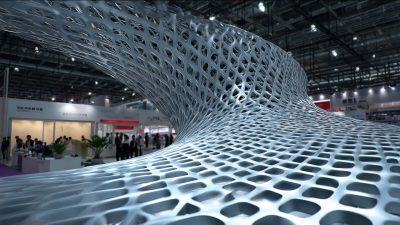

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025

-

Innovative Trends and Market Insights for Welded Wire Mesh at the 2025 China Import and Export Fair

-

Revitalize Your Cleaning Routine: Discover the Power of Steel Brushes for Every Task

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

Exploring the Benefits of Steel Mesh: The Ultimate Guide for Builders and DIY Enthusiasts