Essential Tips for Choosing the Right Stainless Steel Mesh for Your Project

When embarking on a project that requires the right materials, selecting the appropriate stainless steel mesh can be pivotal to its success. As industry expert Dr. James Holloway, a leading figure in material engineering, wisely states, “The choice of stainless steel mesh can significantly influence both the durability and efficiency of your project.” This insight highlights the importance of understanding the various types and applications of stainless steel mesh before making a decision.

Stainless steel mesh is not merely a functional component; it is an integral part of diverse projects, ranging from architectural designs to industrial applications. Choosing the right type involves evaluating factors such as mesh size, material grade, and the specific environmental conditions it will face. By considering these elements, you can ensure that your project not only meets aesthetic and functional requirements but also stands the test of time.

In this guide, we will explore essential tips to help you navigate the selection process effectively, ensuring that you find the perfect stainless steel mesh tailored to your project’s specific needs. Understanding these critical aspects will empower you to make informed decisions that enhance the overall quality and durability of your work.

Understanding the Basics of Stainless Steel Mesh Types

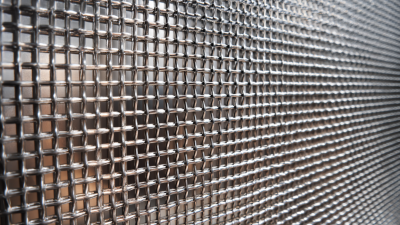

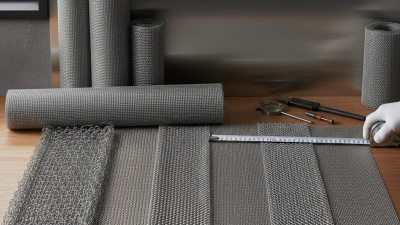

Understanding the basics of stainless steel mesh types is crucial for selecting the right material for your project. Stainless steel mesh comes in various configurations, the most common being welded, woven, and expanded types. According to the International Stainless Steel Forum, the unique properties of stainless steel—such as its corrosion resistance and strength—make it a versatile choice for diverse applications, ranging from construction to food processing.

Woven stainless steel mesh is often preferred in applications requiring high cleanliness standards, such as filtration systems, due to its uniform openings and ease of cleaning. On the other hand, welded mesh is known for its structural integrity and is typically utilized in industrial settings for structural support and safety barriers. Reports show that the global stainless steel mesh market is anticipated to reach approximately $1.3 billion by 2027, growing at a CAGR of 3.5% from 2021. This growth is driven by the increasing demand across various sectors, emphasizing the importance of selecting the correct mesh type to meet specific project requirements.

Key Factors to Consider When Selecting Stainless Steel Mesh

When selecting stainless steel mesh for your project, several key factors should guide your decision-making process. Firstly, consider the mesh wire diameter and opening size. A finer mesh with smaller openings may be more suitable for applications requiring filtration or separation of small particles, while a coarser mesh is ideal for structural support and larger debris containment. Assessing the appropriate thickness and width will also ensure that the mesh meets the strength demands of your specific project.

Another crucial factor is the type of stainless steel used in the mesh. Different grades of stainless steel offer varying levels of corrosion resistance, strength, and durability. Selecting a higher grade, such as 316 stainless steel, can be beneficial for environments exposed to harsh weather conditions or chemicals. Always ensure that the stainless steel mesh aligns with the environmental conditions it will encounter to prolong its lifespan.

Tips for choosing the right stainless steel mesh include evaluating your project's specific requirements, such as load-bearing capacities and environmental exposure. Additionally, consulting with experts in materials can provide insights into the most suitable options based on your project’s needs. Finally, consider the manufacturing method of the mesh, as different techniques can influence its structural integrity and performance, ensuring you make a well-informed choice.

Essential Tips for Choosing the Right Stainless Steel Mesh for Your Project

| Mesh Type | Wire Diameter (mm) | Aperture Size (mm) | Material Grade | Corrosion Resistance |

|---|---|---|---|---|

| Woven Mesh | 0.8 | 1.0 | 304 | Good |

| welded Mesh | 1.0 | 2.0 | 316 | Excellent |

| Expanded Metal | 1.5 | 3.0 | 304 | Good |

| Perforated Sheet | 1.2 | 1.5 | 430 | Moderate |

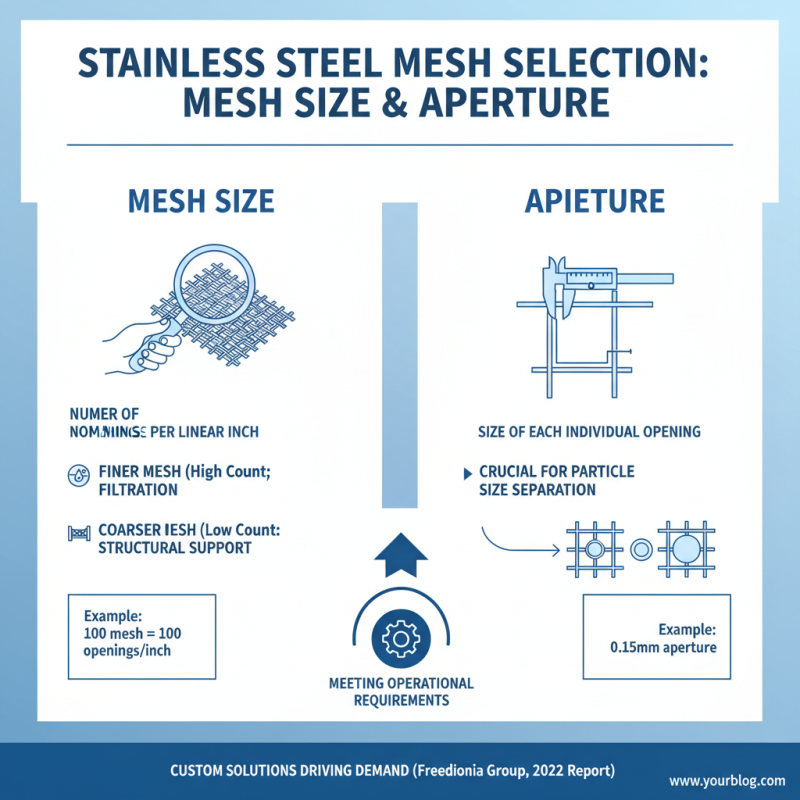

Evaluating Mesh Size and Aperture for Your Specific Needs

When selecting stainless steel mesh for a project, the evaluation of mesh size and aperture is crucial in meeting specific operational requirements. Mesh size refers to the number of openings per linear inch, while aperture indicates the size of each opening. According to a 2022 market analysis report by Freedonia Group, the demand for custom mesh solutions, tailored to the specific applications, has been on the rise, particularly in industries such as construction, agriculture, and food processing. The mesh size must align with the intended use; for instance, finer meshes with a higher number of openings are suitable for filtration purposes, while coarser meshes are more appropriate for structural support.

Moreover, understanding the aperture size is essential in achieving desired functionality. The aperture must be large enough to allow necessary materials to pass through without clogging, yet small enough to retain unwanted debris. According to the latest data from Research and Markets, the stainless steel mesh sector is projected to grow by 5.9% annually from 2023 to 2028, driven by advancements in manufacturing processes that allow for the production of more precise aperatures. Therefore, assessing the ideal mesh size and aperture based on detailed project specifications will enhance the effectiveness and longevity of the mesh installation in various applications.

Comparing Durability and Corrosion Resistance in Stainless Steel Mesh

When selecting stainless steel mesh for your project, durability and corrosion resistance are two critical factors that can significantly impact the longevity and effectiveness of the material in various applications. According to a report by the International Stainless Steel Forum, stainless steel exhibits exceptional strength and durability, with certain grades capable of withstanding extreme environments, including high temperatures and harsh chemicals. For example, grade 316 stainless steel is often recommended for marine environments due to its superior resistance to saline conditions, making it an excellent choice for applications that may be exposed to corrosive elements.

In terms of corrosion resistance, the alloy composition plays a vital role. Research indicates that stainless steel mesh with higher nickel and molybdenum content provides enhanced resistance against pitting and crevice corrosion. Data from the Nickel Institute shows that while standard 304 stainless steel offers decent corrosion resistance, in environments with high chloride exposure, opting for 316 stainless steel can reduce maintenance costs and increase the material's lifespan by up to 50%. Understanding these properties allows engineers and designers to make informed choices tailored to the specific demands of their projects, ensuring both durability and functionality in their designs.

Assessing Cost and Availability for Your Project Requirements

When it comes to selecting the right stainless steel mesh for your project, understanding the cost and availability is crucial. According to a report from the Global Stainless Steel Market, the demand for stainless steel products is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2028. This growth is not solely driven by the construction and automotive industries but also by the rising applications in food processing and industrial sectors. As such, procurement managers must keep a close eye on market fluctuations that can affect the costs of stainless steel mesh, ensuring that budgetary limits are adhered to while also fulfilling project specifications.

Availability of stainless steel mesh can vary greatly depending on the supplier and region. Based on data from industry publications, like the Stainless Steel Wire Mesh Manufacturers Association, many regions are experiencing supply chain disruptions, which can lead to extended lead times for orders. It's recommended to establish relationships with multiple suppliers to mitigate risks associated with availability. Conducting a thorough analysis of inventory levels and regional production capabilities can help in selecting the right product on time. Additionally, understanding the material grades and specifications, such as ASTM or ISO standards, ensures that the selected mesh meets project demands while remaining within cost constraints, ultimately leading to more successful project outcomes.

Cost Comparison of Various Stainless Steel Mesh Types

Related Posts

-

Why Stainless Steel Mesh Screens Are Essential for Your Home and Industry Needs

-

2025 How to Choose the Best Stainless Steel Mesh Screen for Your Needs

-

10 Best Stainless Steel Mesh Options for Versatile Applications

-

Discover the Best Wire Brush Drill Attachments of 2025 for Efficient Cleaning and Rust Removal

-

Top 10 Wire Brush Drill Attachments for Efficient Cleaning and Stripping

-

Best Small Wire Brush Options for Cleaning and Maintenance in 2025