10 Essential Tips for Choosing the Right Weld Mesh for Your Project?

Choosing the right weld mesh for your project can significantly impact its overall success. The weld mesh market has grown substantially, with a 5% annual increase reported in 2022. Industrial applications often demand high-quality materials that meet stringent standards. Renowned industry expert Dr. Andrew Miller once stated, "Selecting the right weld mesh is crucial; the quality directly affects safety and durability."

In terms of specifications, various types of weld mesh serve different needs. For instance, galvanized mesh offers corrosion resistance, while stainless steel mesh provides strength. Factors such as the size of the openings, wire diameter, and material type play a vital role in project outcomes. It's essential to consider the application context to avoid costly mistakes.

Many projects overlook critical details. Working with inappropriate mesh can lead to structural failures and increased costs. By understanding the specific requirements of your project, you can make informed decisions. The right weld mesh not only enhances durability but also ensures compliance with industry standards. Choose wisely; your project’s future may depend on it.

Understanding Different Types of Weld Mesh and Their Applications

Weld mesh comes in various types, each suited for different applications. Common types include square, rectangular, and hexagonal mesh. Square weld mesh is ideal for fencing and partitions. Rectangular mesh is often used for industrial purposes. Hexagonal mesh is popular in agricultural settings.

When selecting the right weld mesh, consider its strength and durability. How will it be used? Will it face extreme weather? For light applications, a thinner wire may suffice. However, heavy-duty projects need robust mesh. Ensure you assess your project requirements thoroughly.

Another tip involves the size of the openings. Larger openings allow for better airflow but may compromise security. Smaller openings enhance safety but could limit visibility. Balance these factors according to your project needs. Remember, choosing a weld mesh is not just about looks; functionality plays a crucial role.

Assessing Material Options for Weld Mesh: Steel, Stainless Steel, and More

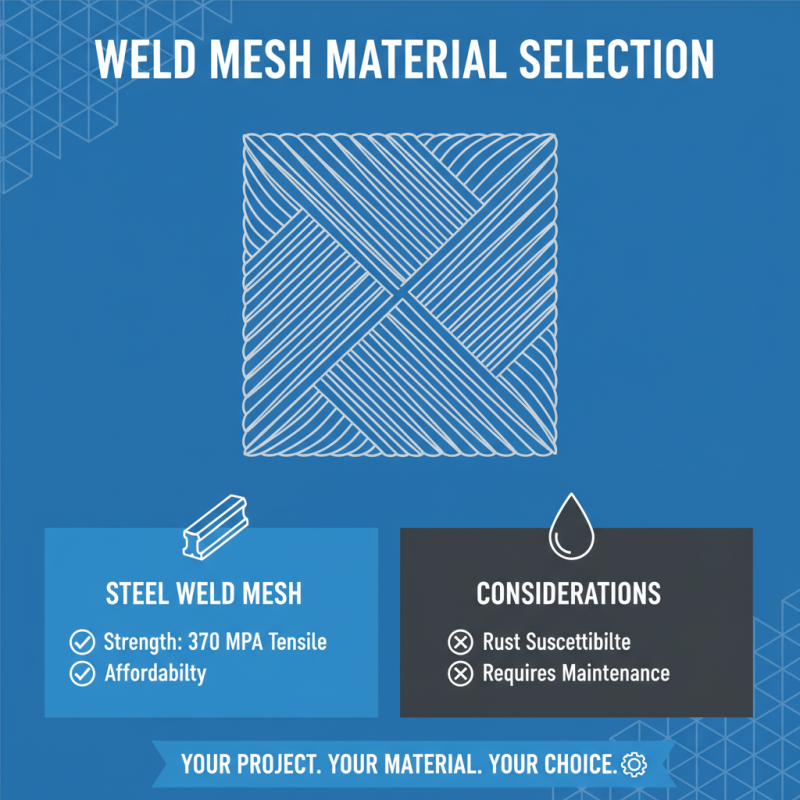

When selecting the right weld mesh for your project, material choice plays a crucial role. Steel is a popular option due to its strength and affordability. According to industry data, it has a tensile strength around 370 MPa, making it suitable for structural applications. However, its susceptibility to rust can be a concern in certain environments. Regular maintenance is essential if you choose steel.

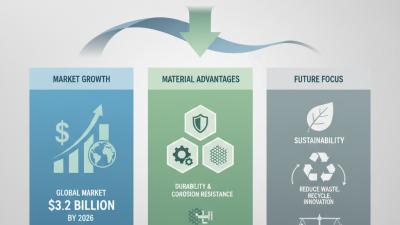

Stainless steel offers an excellent alternative. With a tensile strength of approximately 520 MPa, it withstands harsher conditions much better. Its corrosion resistance is a major advantage, especially in outdoor or food processing applications. However, the cost can be a limiting factor for some projects. You'll often find that stainless steel mesh is about 30% more expensive than its steel counterpart.

Other options, such as fiberglass or plastic, may work well for less demanding projects. They are lighter and resistant to chemicals. However, their load-bearing capacity is significantly lower. Ultimately, the decision should reflect the specific requirements of your project, considering factors like environmental conditions and budget constraints. Remember that choosing the wrong type can lead to unexpected failures.

Mesh Size and Wire Diameter: What to Consider for Your Project

When selecting weld mesh, mesh size and wire diameter are crucial. The mesh size determines how tightly the material can retain objects or substances. A smaller mesh will provide better containment for small items. For instance, if you're working on a garden project, consider using a mesh size that keeps out pests while allowing air and water circulation. Each project needs careful assessment to ensure the chosen mesh will serve its purpose effectively.

Wire diameter also plays a significant role. Thicker wires can withstand higher loads and offer improved durability. However, they might limit flexibility in various installations. A balance is necessary. Using a thinner wire might seem cost-effective but could lead to early wear or breakage. Visualizing your project's demands can clarify whether strength or flexibility is more critical. Reflecting on past projects might reveal lessons learned about the right mesh specifications.

Evaluating Corrosion Resistance and Durability of Weld Mesh

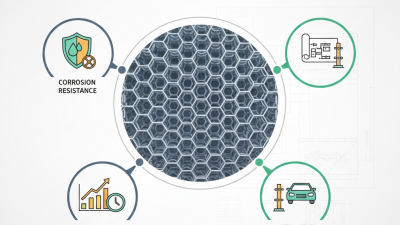

When selecting weld mesh for your project, corrosion resistance and durability should be key considerations. Corrosion can severely compromise the integrity of weld mesh, especially in harsh environments. Look for materials with a protective coating or those made from stainless steel. These options often resist rust and provide longer-lasting performance.

However, not all coatings are created equal. Some may wear off over time, leading to rust formation underneath. It’s crucial to examine product specifications closely. Consider the environment where the mesh will be used. Factors like humidity, exposure to chemicals, and temperature fluctuations can all impact durability. The right choice will balance initial cost with long-term effectiveness.

Testing is another aspect that can’t be overlooked. Ask about the corrosion resistance ratings and durability tests conducted. Real-world performance can sometimes differ from laboratory results. A good weld mesh should withstand challenges over time, but it’s wise to keep an eye on its condition regularly. Knowing when to replace the mesh can prevent greater issues down the line.

Cost Considerations: Budgeting for Your Weld Mesh Needs

When budgeting for weld mesh, every detail matters. Begin by determining the size and type of mesh you need. Consider the gauge and spacing of the wires, as these factors influence the overall cost. A finer mesh might be more expensive but can provide better support. Balance your project requirements with your budget constraints.

Another important aspect is the quantity needed. Bulk purchasing often leads to discounts, but do you really need that much? Overestimating can inflate your costs unnecessarily. Additionally, factor in shipping and handling fees, as they can significantly impact your budget. Take time to compare prices from various suppliers. Just ensure you're not compromising quality for a mere discount.

Don't forget about the long-term implications of your choice. Cheaper options may seem appealing, but poor quality can lead to frequent replacements. Reflect on whether the lower upfront cost is worth the potential future expenses. Investing in better-quality weld mesh may offer more value in the long run.

10 Essential Tips for Choosing the Right Weld Mesh for Your Project

| Dimension | Material | Mesh Size (mm) | Cost per Square Meter ($) | Recommended Use |

|---|---|---|---|---|

| 1m x 2m | Steel | 25 | 30 | Fencing |

| 1m x 1m | Stainless Steel | 15 | 50 | Food Industry |

| 2m x 3m | Aluminum | 20 | 40 | Construction |

| 4m x 2m | Coated Steel | 30 | 35 | Agriculture |

| 3m x 1m | Galvanized Steel | 10 | 25 | Industrial Use |

Related Posts

-

Why You Should Choose Galvanized Wire Mesh for Your Next Project

-

Top 10 Best Stainless Steel Wire Mesh Options for Your Projects?

-

Why is Welded Wire Mesh Essential for Construction and Agriculture?

-

2026 Top Trends in Stainless Steel Wire Mesh Applications?

-

How to Choose the Right MIG Wire for Your Welding Projects

-

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects