10 Essential Tips for Using a Wire Brush Effectively in Your Projects

When it comes to achieving a high level of surface preparation and finishing in various projects, the wire brush has become an essential tool across multiple industries. According to a recent report by the Machinery Tool Industry Association, over 60% of manufacturers now utilize wire brushes for tasks ranging from rust removal to surface conditioning, highlighting their effectiveness and versatility. An industry expert, James L. Carter, emphasizes that "the wire brush is not just a tool; it’s a gateway to achieving precision and quality in metalworking."

The wire brush's unique design enables users to tackle difficult cleaning jobs with ease, making it an indispensable component in workshops and construction sites alike. As the demand for intricate and clean finishes increases, understanding how to use a wire brush effectively has never been more critical. A study published in the Journal of Metal Processing indicates that improper usage of wire brushes can lead to inconsistent results and increased wear on both the tool and the workpiece. Therefore, mastering the techniques associated with wire brush applications can significantly enhance project outcomes and extend tool lifespan.

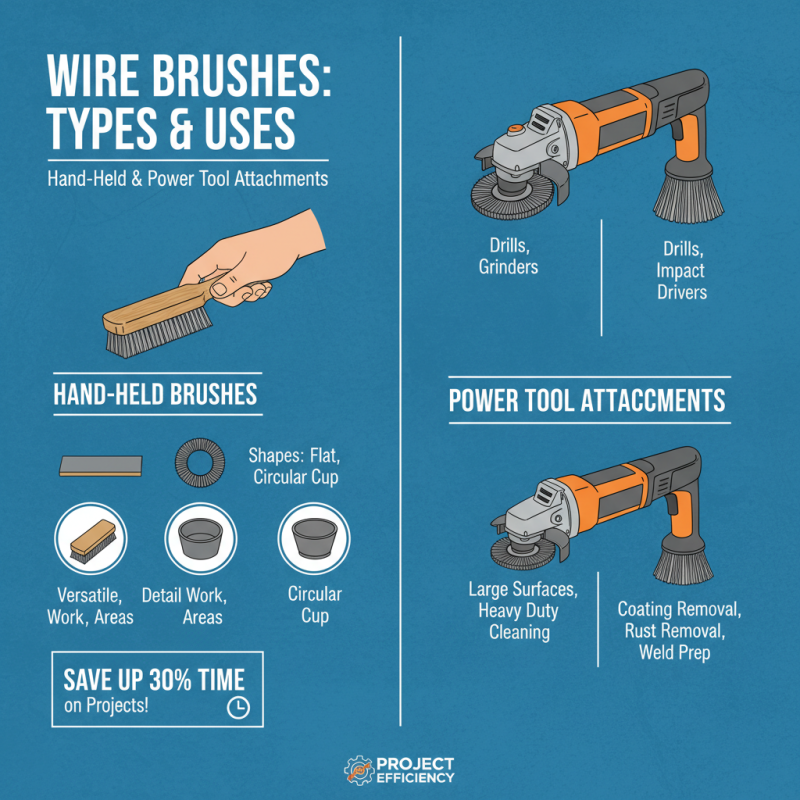

Understanding the Different Types of Wire Brushes and Their Uses

Wire brushes come in various types, each designed for specific applications, making it crucial to understand their uses for effective project execution. The two primary categories of wire brushes are hand-held brushes and power tool attachments. Hand-held brushes are versatile and ideal for detail work or small areas. They are available in various shapes, from flat to circular, and can be tailored to achieve various surface finishes. According to industry reports, effectively selecting the right hand-held wire brush can reduce work time by up to 30%, enhancing project efficiency.

Power tool attachments, including cup brushes and wheel brushes, offer accelerated cleaning and surface preparation for larger projects. These brushes are designed to withstand heavy-duty applications, making them perfect for removing rust, paint, or corrosion from metal surfaces. A recent study highlighted that using a power tool wire brush can improve performance speed by nearly 50% compared to manual methods. Understanding the materials used in wire brushes — such as steel, brass, or stainless steel — is vital, as each type offers different abrasive qualities and durability levels, ensuring that users can achieve optimal results based on their specific project needs.

Choosing the Right Wire Brush for Your Specific Project Needs

When selecting the right wire brush for your specific project needs, consider the material you will be working with, as this plays a crucial role in achieving optimal results. For instance, stainless steel brushes are great for softer materials like aluminum, as they offer a gentle approach while effectively removing oxidation and debris without damaging the surface. Conversely, if you're working with tougher surfaces or heavy rust, a harder bristle, such as those made from carbon steel, will provide the aggressive scrubbing action required to prepare the surface for further treatment or painting.

Additionally, the size and shape of the wire brush are vital factors to contemplate. For larger, flat surfaces, a wider brush can cover more area quickly, but fine detailing may necessitate a smaller, more precise brush. Angle brushes or wheel brushes can be particularly useful for getting into tight spaces or uneven surfaces. It's essential to match the brush type to the specific contours and requirements of your project to ensure effective cleaning and surface preparation. This thoughtful selection process will not only enhance the efficiency of your work but also improve the overall quality of the results.

Techniques for Properly Holding and Maneuvering the Wire Brush

When using a wire brush, proper handling and maneuvering techniques are crucial for achieving the best results while ensuring safety. Start by gripping the brush firmly but comfortably. Hold the handle with a dominant hand, allowing your fingers to wrap around it securely. This grip provides control and minimizes the risk of slipping during use. Your other hand should rest lightly on the brush head to guide the movement, offering stability and support. Maintaining a balanced posture and keeping your elbows close to your body will help reduce strain and improve your precision.

When maneuvering the wire brush, it's essential to understand the direction of the bristles and the surface you’re working on. For effective cleaning or surface preparation, apply even pressure while moving the brush in a linear fashion. This technique minimizes the risk of damaging the surface and ensures that you effectively remove debris and rust. Additionally, adjust the angle of the brush to match the contours of the item you're working on; this will enhance your ability to reach tight spots and achieve a consistent finish. Always remember to clean the brush regularly to maintain its effectiveness and prolong its life.

Safety Precautions to Consider When Using Wire Brushes

When using wire brushes in your projects, it is crucial to prioritize safety to prevent injuries and ensure effective results. One of the primary precautions to consider is wearing appropriate personal protective equipment (PPE). This includes safety goggles to protect your eyes from flying debris, gloves to shield your hands from sharp wire bristles, and a dust mask or respirator if you are working in an environment where inhalation of particles is a risk. Ensuring that you have the right gear can significantly reduce the likelihood of accidents.

Additionally, it is important to use the wire brush correctly to minimize risks. Always inspect the brush before use to ensure that the bristles are securely attached and not damaged. Operate the brush at a safe distance from your body and work in a well-ventilated area to avoid the accumulation of dust. Keeping the workpiece stable and using the appropriate angle of approach can help maintain better control over the brush, reducing the chances of slips that could lead to injury. By adhering to these safety measures, you can effectively utilize wire brushes while protecting yourself and achieving the desired results in your projects.

Wire Brush Effectiveness in Different Applications

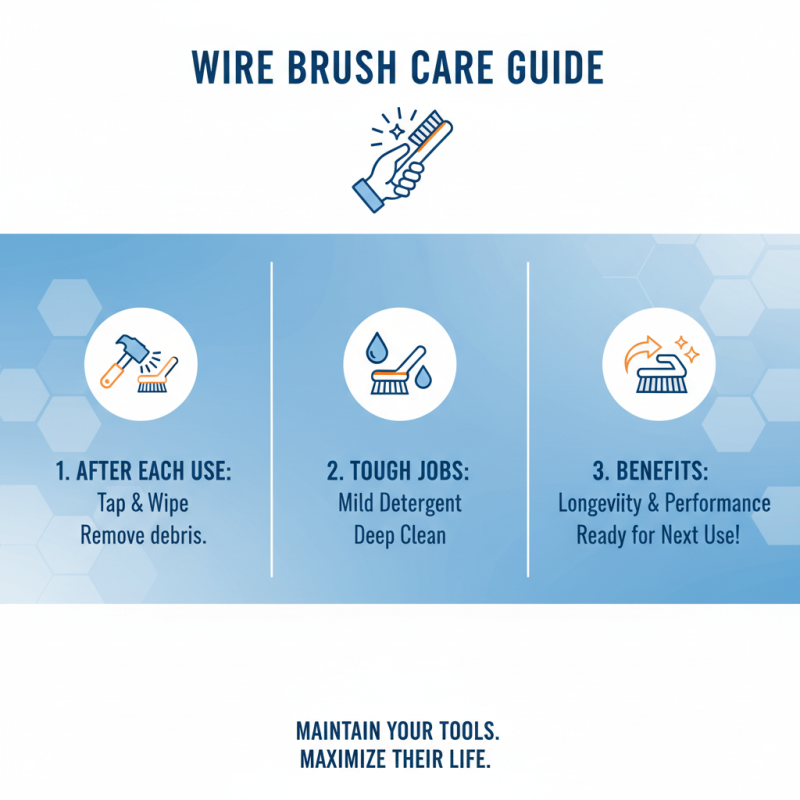

Maintaining and Caring for Your Wire Brushes to Extend Their Lifespan

To ensure that your wire brushes last as long as possible, proper maintenance and care are essential. After each use, it’s important to remove any debris or buildup from the bristles. This can be accomplished by gently tapping the brush against a hard surface or using a soft cloth to wipe away any residue. For brushes used on tougher materials, a mild detergent solution can be used to clean the bristles thoroughly. This routine not only keeps the brush clean but also helps maintain its effectiveness for future projects.

Additionally, storing wire brushes correctly can significantly extend their lifespan. They should be kept in a dry environment and away from moisture, which can lead to rusting and deterioration of the bristles. Hanging the brushes or storing them in a dedicated toolbox can prevent them from getting bent or damaged. Finally, inspecting the brushes regularly for wear and tear is crucial. If the bristles are frayed or bent, it may be time to replace the brush, as using a worn tool can compromise the quality of your work. By incorporating these maintenance practices, you can ensure that your wire brushes remain in optimal condition, ready to tackle your projects effectively.

Related Posts

-

Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

10 Best Stainless Steel Mesh Options for Versatile Applications

-

2025 How to Choose the Best MIG Wire for Optimal Welding Performance

-

How to Choose the Right MIG Wire for Your Welding Projects

-

Why Choosing the Right Stainless Steel Manufacturers Matters for Your Projects