Finding the best manufacturers worldwide is crucial for businesses aiming to thrive in today's global marketplace. The manufacturing industry is projected to grow to approximately $5 trillion by 2030, according to a report by McKinsey & Company, highlighting the significant role of manufacturers in driving economic growth and innovation.

However, businesses often face numerous challenges in identifying reliable and efficient manufacturers that meet their specific needs. Issues such as supply chain disruptions, varying quality standards, and regional compliance regulations can complicate the sourcing process.

To navigate these challenges effectively, companies must implement strategic solutions that ensure they partner with the right manufacturers, ultimately enhancing their operational efficiency and market competitiveness. In this blog, we will explore effective strategies for finding and evaluating manufacturers worldwide, addressing the common problems businesses encounter in this critical process.

When identifying quality manufacturers, it’s essential to focus on key attributes that indicate their reliability and credibility. One major attribute to consider is the manufacturer’s compliance with industry standards. A manufacturer that adheres to recognized safety and quality regulations shows a commitment to producing high-quality products. Additionally, their ability to demonstrate transparency in their processes and supply chain can significantly enhance trust.

Another important aspect is the manufacturer's experience and expertise in specific product categories. An established manufacturer typically has refined production techniques and better problem-solving capabilities. Look for testimonials or case studies that reflect their past successes. This not only offers insights into their operational capabilities but also highlights their adaptability to market demands.

**Tips:** Assess the manufacturer's quality assurance practices, as effective quality control leads to consistent product performance. Engage with them directly to understand their production processes and ask for certifications that verify their claims. Finally, consider their approach to sustainability; manufacturers that integrate environmentally friendly practices often exhibit a higher level of commitment to quality and innovation.

| Attribute | Description | Importance Level |

|---|---|---|

| Experience | Number of years in the manufacturing industry. | High |

| Certifications | Relevant industry certifications (ISO, etc.). | Critical |

| Product Quality | Consistency and reliability of product output. | High |

| Technology | Use of modern manufacturing technologies and processes. | Medium |

| Customer Service | Responsiveness and support provided to clients. | High |

| Scalability | Ability to handle increasing production demands. | Medium |

| Reputation | Industry standing and client testimonials. | Critical |

| Cost Efficiency | Competitive pricing without compromising quality. | High |

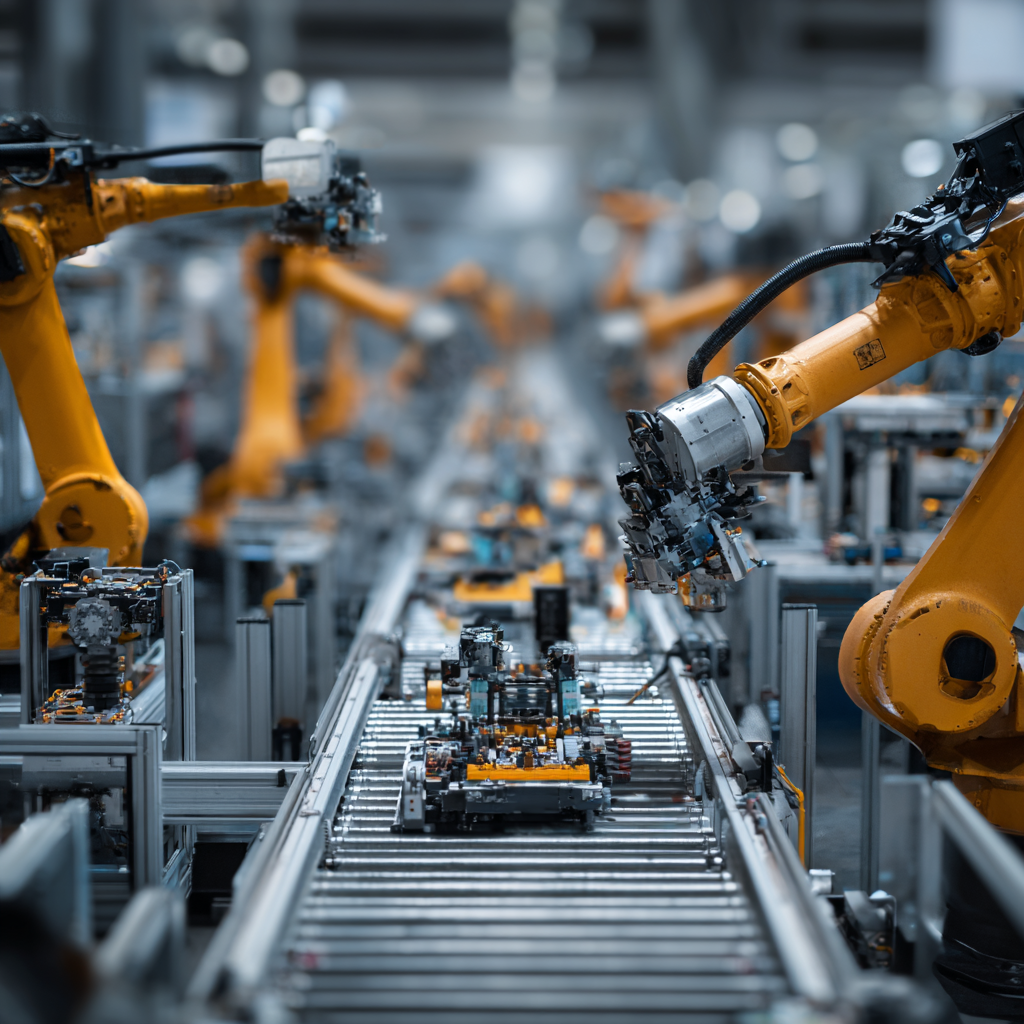

In today’s global marketplace, finding reliable manufacturers is crucial for businesses aiming to optimize their supply chains. Leveraging online platforms has transformed the way companies conduct supplier searches, making the process not only more efficient but also more transparent. Websites dedicated to connecting buyers with manufacturers, such as Alibaba, ThomasNet, and Maker’s Row, provide comprehensive databases that allow businesses to evaluate potential suppliers based on their location, specialization, and credentials.

These platforms often include user reviews and ratings, which serve as a valuable resource for assessing a manufacturer’s reliability and quality of products. Additionally, many online tools offer features like request-for-quote (RFQ) submissions, enabling businesses to compare prices and capabilities from multiple suppliers at once. With the ability to filter results by criteria such as minimum order quantity and manufacturing capabilities, companies can easily find the best fit for their needs, saving valuable time and resources along the way. By harnessing the power of digital tools, businesses can confidently navigate the complex landscape of global manufacturing and forge partnerships that enhance their competitive edge.

Building robust relationships is essential for successful partnerships with manufacturers. Networking strategies can significantly enhance these connections. According to a report by the Manufacturers Alliance for Productivity and Innovation, 70% of manufacturers believe that strong partnerships are crucial for achieving operational excellence.

Leveraging industry events, trade shows, and online platforms can provide invaluable opportunities to meet potential partners, share insights, and cultivate trust. Effective networking is not merely about exchanging business cards; it’s about fostering genuine relationships that can lead to long-term collaborations.

Building robust relationships is essential for successful partnerships with manufacturers. Networking strategies can significantly enhance these connections. According to a report by the Manufacturers Alliance for Productivity and Innovation, 70% of manufacturers believe that strong partnerships are crucial for achieving operational excellence.

Leveraging industry events, trade shows, and online platforms can provide invaluable opportunities to meet potential partners, share insights, and cultivate trust. Effective networking is not merely about exchanging business cards; it’s about fostering genuine relationships that can lead to long-term collaborations.

Furthermore, utilizing social media and professional networks like LinkedIn can amplify these relationships. A survey conducted by IndustryWeek found that over 60% of manufacturers engage in social media to find and connect with partners. By actively participating in discussions, sharing industry challenges, and showcasing expertise, manufacturers can position themselves as reliable partners. Developing a strategic approach to networking can open doors to innovative solutions and best practices that help businesses thrive in a competitive landscape. Building these connections is not just beneficial—it’s essential for navigating the complexities of global manufacturing.

Finding reliable manufacturers is crucial for businesses looking to scale their operations effectively. One of the most valuable tools in evaluating manufacturer reliability is the use of third-party audits. These audits assess various factors, including production capabilities, quality control processes, and compliance with industry standards. By engaging independent auditors, companies can gain objective insights into potential manufacturing partners, minimizing the risk of quality issues and supply chain disruptions.

In addition to audits, leveraging technology can enhance the evaluation process. Online platforms and software tools designed for supplier management offer features such as real-time performance tracking and customer reviews. These tools allow businesses to analyze historical data, monitor compliance metrics, and stay updated on any issues that may arise. Emphasizing data-driven decision-making not only streamlines the sourcing process but also builds a stronger foundation for long-term partnerships with reliable manufacturers worldwide.

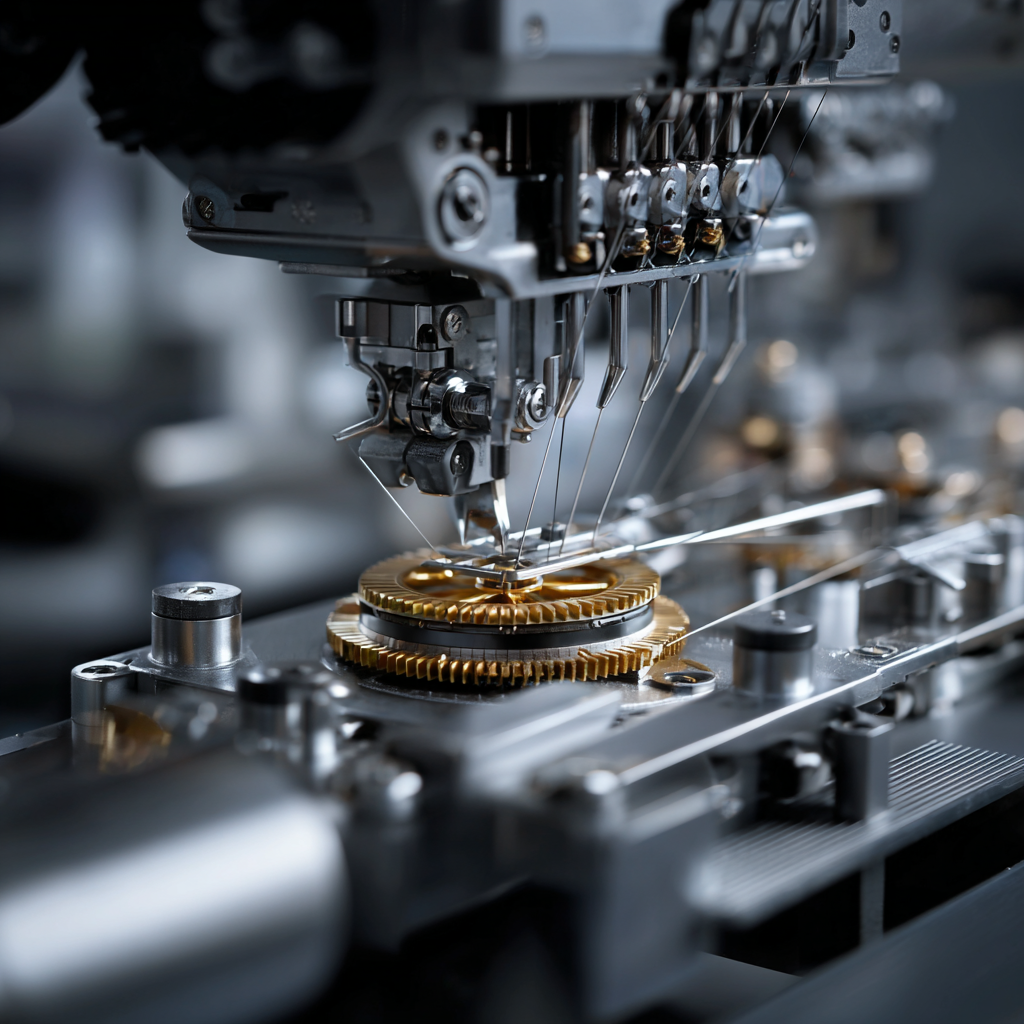

Conducting effective factory audits is crucial for ensuring quality control in manufacturing. A well-structured audit helps identify potential risks and weaknesses within the production processes. By assessing everything from compliance with safety regulations to checking the integrity of raw materials, auditors can gain insights into a manufacturer’s operational capability. This proactive approach not only safeguards product quality but also enhances the overall supply chain efficiency.

During a factory audit, it's essential to establish clear criteria for assessment. Engaging with factory personnel and understanding their workflows can reveal valuable information about their practices. Additionally, employing checklists tailored to specific industry standards ensures that all critical aspects are thoroughly examined.

By prioritizing transparency and open communication, businesses can foster a collaborative environment that encourages continuous improvement. Ultimately, effective factory audits serve as a strategic tool for businesses looking to partner with reliable manufacturers and uphold the highest standards of quality control.