2025 How to Choose the Best MIG Wire for Optimal Welding Performance

In the world of welding, selecting the right MIG wire is crucial for achieving optimal performance and results. As the renowned welding expert, Dr. Emily Parker, once stated, “The quality of your MIG wire can make all the difference between a strong, reliable weld and a project fraught with issues.” With a plethora of options available on the market, making an informed choice can be daunting for both seasoned welders and beginners alike.

This article delves into the top ten MIG wires available in 2025, examining their characteristics, applications, and the performance they offer. From stainless steel to aluminum, understanding the specific advantages of each type of MIG wire plays a critical role in ensuring the success of your welding projects. By analyzing these options, we aim to equip welders with the knowledge necessary to choose the best MIG wire, ultimately enhancing their performance and satisfaction.

Whether you are fabricating automotive parts, constructing art pieces, or undertaking home repairs, the right MIG wire is essential to elevate your welding endeavors to the highest standard.

Factors to Consider When Selecting MIG Wire for Welding Projects

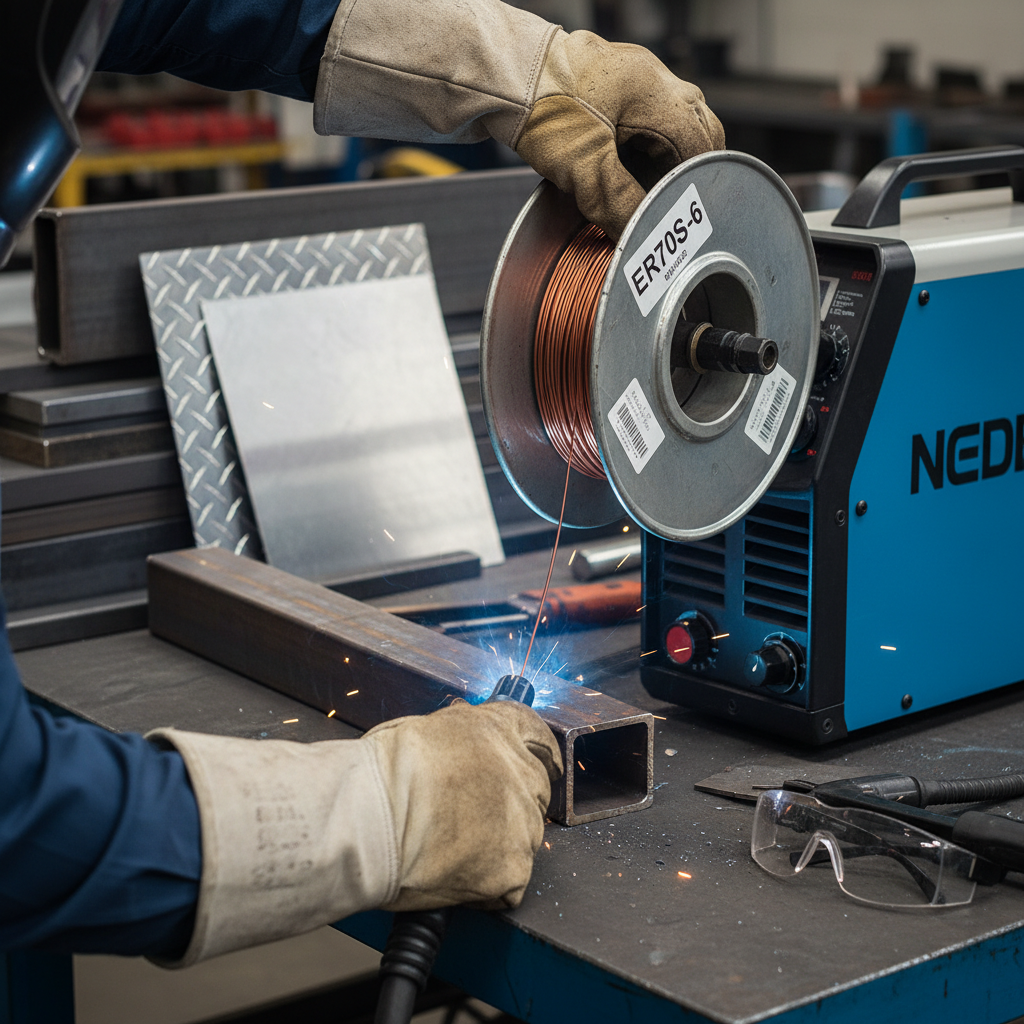

When selecting the best MIG wire for welding projects, several key factors should be considered to ensure optimal performance. First and foremost, understanding the type of material being welded is crucial. Different metals, such as mild steel, stainless steel, or aluminum, require specific wire compositions. For instance, ER70S-6 is highly suitable for mild steel due to its excellent deoxidizing properties, which help produce high-quality welds. Thus, knowing the base material helps in choosing the right wire to achieve strong and clean welds.

Another important factor is the wire diameter, which significantly influences the heat input and penetration of the weld. Typically, a thicker wire is better for producing deeper welds, while a thinner wire is suited for more delicate applications. Additionally, the shielding gas used in combination with MIG wire can impact the outcome of the welding process. The selection of the appropriate gas mixture, such as Argon-CO2 for steel or pure Argon for aluminum, can enhance arc stability and minimize spatter. By considering these elements, welders can effectively choose the MIG wire that will yield the best results for their specific projects.

Understanding Different Types of MIG Wire Materials and Their Applications

When it comes to choosing the best MIG wire for optimal welding performance, understanding the different types of MIG wire materials is essential. The most common types include

carbon steel, stainless steel, and aluminum wires. Carbon steel MIG wire is ideal for general fabrication and structural projects due to its excellent strength and affordability.

Stainless steel wire, with its outstanding corrosion resistance, is better suited for applications requiring enhanced durability, such as in the food and medical industries. For lightweight projects or applications demanding excellent weldability,

aluminum MIG wire is a top choice.

Tips: When selecting MIG wire, consider the specific application and positional welding required. For thicker materials, a higher wire diameter may be necessary to ensure thorough penetration and strong welds. Additionally, always match the wire type with the appropriate shielding gas for optimal arc stability and weld quality.

In addition to material types, pay attention to the coating and diameter of the MIG wire. A flux-cored wire may be beneficial in outdoor conditions as it provides a protective layer, whereas solid wire works well in controlled environments. Ultimately, your choice in MIG wire will significantly impact the final quality and durability of your welds.

Evaluating MIG Wire Diameter for Optimal Welding Results

When it comes to achieving optimal welding results, the diameter of your MIG wire plays a crucial role in determining the quality and efficiency of your welds. Industry studies suggest that the most common MIG wire diameters—0.030 inches, 0.035 inches, and 0.045 inches—serve different applications and materials. A thinner wire, like 0.030 inches, is generally better for welding thin materials (under 1/8 inch) due to its ability to produce a more controlled arc. Conversely, a thicker wire, such as 0.045 inches, is ideal for heavy-duty applications and thicker materials, as it can provide increased deposition rates and better penetration.

Tips: Consider the material thickness and type when selecting your MIG wire diameter. For instance, E71T-11 is often used for general-purpose welding on mild steel, with a diameter of 0.035 inches being the sweet spot for versatility. According to the American Welding Society, using the proper wire diameter can reduce defects such as undercutting or lack of fusion, significantly enhancing weld quality.

Furthermore, the welding position should also be factored into your decision. For overhead welding, a smaller diameter wire might be advantageous because it reduces the weight and prevents the molten metal from sagging. By accurately assessing these factors, welders can optimize their performance and achieve superior results in their projects.

Comparing Solid vs. Flux-Cored MIG Wire for Specific Welding Needs

When it comes to selecting the optimal MIG wire for your welding projects, understanding the differences between solid and flux-cored wires is crucial. Solid wires are typically used with a shielding gas, making them ideal for clean and thin materials. They provide a strong, high-quality weld but may not be suitable for outdoor or windy conditions. In contrast, flux-cored wires don’t require an external shielding gas, offering greater versatility for working in less-than-ideal environments. This makes them an excellent choice for outdoor applications or welding in challenging positions.

According to recent market analysis, the U.S. welding consumables market is projected to experience significant growth, driven by demand for varied welding products. Solid wires and flux-cored wires are critical components of this market, which also includes stick electrodes and submerged arc welding wires. As the construction and manufacturing industries evolve, knowing when to utilize solid versus flux-cored wires can enhance welding performance. For example, flux-cored wires accounted for 20% of the welding wire market share in 2022, reflecting their growing popularity among welders needing flexibility and ease of use. This trend indicates a shift towards more adaptable welding solutions, catering to specific requirements and environments.

2025 How to Choose the Best MIG Wire for Optimal Welding Performance

| MIG Wire Type | Best For | Welding Position | Material Thickness | Ease of Use | Cost |

|---|---|---|---|---|---|

| Solid MIG Wire | Thin materials & automotive welding | Flat, horizontal | Up to 1/4 inch | Moderate | $$$ |

| Flux-Cored MIG Wire | Thicker materials & outdoor welding | All positions | Up to 1/2 inch | Easy | $$ |

| Gas-Shielded Solid Wire | Precision welding | Flat, horizontal, vertical | Thin to medium | Moderate | $$$$ |

| Self-Shielded Flux-Cored Wire | Field and construction applications | All positions | Medium to heavy | Very easy | $ |

Tips for Matching MIG Wire with Various Welding Machines and Techniques

When selecting the best MIG wire for optimal welding performance, it’s essential to consider the compatibility with different welding machines and techniques. Different welding machines require specific types of MIG wires to achieve the best results. For instance, machines designed for gas-shielded welding generally work best with ER70S-6 wires, which provide excellent arc stability and versatility with a range of materials. Conversely, if you’re using a flux-cored welding machine, opting for self-shielded wires can eliminate the need for external gas and enhance convenience in outdoor environments.

Additionally, understanding the materials and thicknesses you intend to weld is crucial. For thin materials, a 0.023-inch wire diameter is ideal as it minimizes burn-through and offers fine control. On heavier sections, larger diameters like 0.035-inch or 0.045-inch are more suitable, ensuring deeper penetration. Matching the MIG wire with the appropriate technique, such as spray transfer for thicker materials or short-circuit transfer for thinner ones, further enhances the quality and strength of the weld, leading to successful outcomes across various welding projects.

2025 MIG Wire Types and Their Optimal Usage

Related Posts

-

Understanding the Essential Role of Steel Rope in Everyday Applications

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

10 Best Stainless Steel Mesh Options for Versatile Applications

-

Exploring the Benefits of Steel Mesh: The Ultimate Guide for Builders and DIY Enthusiasts

-

Exploring the Versatility of Stainless Steel Wire: Applications in Everyday Life and Industry

-

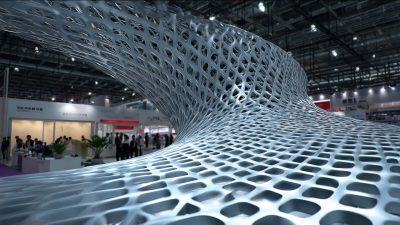

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025