Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

The importance of mastering stainless steel welding techniques cannot be overstated in today’s manufacturing and construction industries. According to a report by the American Welding Society, stainless steel accounts for approximately 40% of all fabricated metal products, highlighting its significance across various applications. Effective stainless steel welding ensures superior joint integrity and enhanced durability, which are critical factors in industries such as aerospace, automotive, and marine engineering. With the demand for durable and high-performance materials on the rise, developing advanced welding skills is essential for professionals to meet the stringent quality standards and corrosion resistance required in modern applications. Furthermore, studies have shown that improper welding techniques can lead to significant increases in maintenance costs and project delays, making it imperative for welders to continuously refine their skills and stay updated with the latest methodologies in stainless steel welding.

Fundamentals of Stainless Steel Welding: Essential Techniques Explained

Welding stainless steel requires a thorough understanding of its unique properties and the techniques that enhance joint integrity and durability. One essential technique is maintaining the right heat input; excessive heat can lead to warping or corrosion, while insufficient heat can result in inadequate fusion. According to the American Welding Society, proper heat control during welding can improve the weld quality and reduce post-weld treatment, which is crucial for maintaining the aesthetic and functional qualities of stainless steel components.

Another critical aspect is the selection of filler materials. Using the appropriate filler that matches the base stainless steel can significantly impact the joint strength and corrosion resistance. The Stainless Steel World journal highlights that using incompatible filler can reduce the overall corrosion resistance of the joint by up to 30%. Additionally, techniques such as TIG (Tungsten Inert Gas) welding are recommended for achieving superior results in stainless steel projects, due to their ability to provide a clean and controlled arc. Mastering these essential techniques not only enhances the quality of the welds but also ensures longevity and reliability in the finished products.

5 Key Tips for Preparing Stainless Steel Surfaces Before Welding

Effective welding of stainless steel requires meticulous surface preparation to ensure strong and durable joints. According to a report by the American Welding Society, nearly 70% of welding failures are attributed to improper surface preparation. Therefore, starting with clean, properly prepared surfaces is crucial for achieving superior results.

One key tip is to thoroughly clean the stainless steel surfaces before welding. This can be achieved using solvents or industrial-grade cleaners to remove any grease, oil, or dirt. Another effective method is mechanical cleaning, which involves grinding or brushing the surface to eliminate any contaminants. By ensuring a clean surface, welders can significantly reduce the risk of defects.

Additionally, it’s important to ensure proper alignment and fit-up of the pieces to be welded. Misalignment can lead to stress concentrations and potential failures. Employing fixtures or clamps can help maintain proper alignment during the welding process. According to the Stainless Steel Council, proper surface preparation along with alignment can enhance the overall strength of the weld joint by up to 25%. Investing time in these preparatory steps will not only improve the quality of the welds but also extend the life of the stainless steel structure.

Mastering Stainless Steel Welding Techniques: Surface Preparation Impact

7 Common Stainless Steel Welding Mistakes and How to Avoid Them

When it comes to stainless steel welding, avoiding common mistakes is crucial for achieving superior joints and durability. One major pitfall is poor surface preparation. Not cleaning the base metal properly can lead to contaminants affecting the weld quality. It is essential to remove any grease, dirt, or oxidation from the surface to promote better fusion and ensure optimal strength in the finished joint.

Another frequent error is incorrect electrode choice. Using an unsuitable filler material can result in weak welds and susceptibility to corrosion. Welders must select the right type of stainless steel filler that matches the base materials to improve joint integrity. Additionally, temperature control during the welding process is vital. Overheating can cause warping or distortion, while insufficient heat promotes incomplete fusion. Therefore, understanding the appropriate heat settings and techniques is imperative in achieving quality welds and avoiding these common mistakes.

The Best Welding Equipment for Stainless Steel Projects: A Comprehensive Guide

When embarking on stainless steel welding projects, choosing the right equipment is paramount to achieving superior joints and ensuring durability. The market offers various options, but equipment like the Titanium 140 Welder stands out as an exceptional choice for both amateurs and seasoned welders. This welder enhances the welding experience with its advanced features, making it suitable for significant upgrades, whether in automotive or industrial applications. Its reliability and efficiency lead to high-quality welds, proving to be a worthwhile investment for those looking to elevate their craft.

Additionally, the trend among farms and ranches reflects a shift towards modern welding techniques, such as wire welding. Products like the newest wire welders provide a shop-quality experience, which is particularly beneficial for large-scale or precision projects. As more welders transition from traditional stick methods to these advanced technologies, understanding the tools available, such as quality welding electrodes and hand-held systems, becomes crucial. This evolution in welding equipment not only improves outcomes but also enhances overall project efficiency and safety.

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

| Welding Technique | Key Features | Ideal Applications | Best Equipment |

|---|---|---|---|

| TIG Welding | High precision, excellent control, clean finish | Thin sections, piping, artistic projects | TIG torch, Argon gas, stainless steel filler rod |

| MIG Welding | Speedy operation, less skill required, versatile | Heavy sections, automotive work, general fabrication | MIG welder, solid wire, shielding gas |

| Stick Welding | Good penetration, portable, outdoor use | Construction, maintenance, thick materials | Stick welder, electrodes (E308), flux |

| Submerged Arc Welding | High deposition rate, minimal smoke, deep penetration | Heavy fabrication, shipbuilding, pressure vessels | SAW equipment, granular flux, wire electrode |

Innovative Welding Methods for Enhanced Durability of Stainless Steel Joints

Innovative welding methods play a crucial role in enhancing the durability of stainless steel joints, which are essential in numerous industries, from construction to manufacturing. Techniques such as laser welding and friction stir welding have emerged as game changers in this domain.

Laser welding uses concentrated light to join materials, resulting in extremely precise and high-quality welds with minimal distortion. This method not only improves the aesthetic appeal of welded joints but also increases their strength, making them suitable for high-stress applications.

Laser welding uses concentrated light to join materials, resulting in extremely precise and high-quality welds with minimal distortion. This method not only improves the aesthetic appeal of welded joints but also increases their strength, making them suitable for high-stress applications.

Friction stir welding, on the other hand, introduces a unique approach by using a rotating tool to generate heat through friction, softening the material without melting it. This process produces joints with superior mechanical properties and resistance to corrosion, a hallmark of stainless steel. By adopting these innovative techniques, fabricators can achieve joints that not only withstand the rigors of their environments but also improve overall structural integrity. As industries continue to demand more from their materials, mastering such advanced methods becomes essential for engineers and welders aiming for excellence in stainless steel fabrication.

Related Posts

-

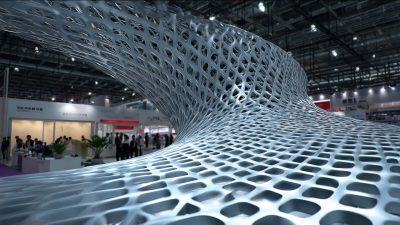

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025

-

Innovative Trends and Market Insights for Welded Wire Mesh at the 2025 China Import and Export Fair

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects