What is a Metal Mesh Screen and How is it Used in Different Applications

Metal mesh screens have become integral components in various industries, delivering functionality and efficiency in filtration, safety, and architectural design. According to a recent industry report by Grand View Research, the global metal mesh market is projected to experience significant growth, driven by the increasing demand for superior filtration solutions across sectors such as aerospace, automotive, and food processing. Metal mesh screens not only provide durability but also flexibility in design, accommodating a wide range of applications from air and liquid filtration systems to architectural elements.

The versatility of metal mesh screens lies in their ability to be customized for specific requirements, whether it is the size of the mesh openings or the material used—ranging from stainless steel to aluminum. These characteristics make them ideal for environments that demand stringent safety and performance standards. For instance, the filtration industry alone is expected to expand, with analysts predicting a compound annual growth rate (CAGR) of over 5% from 2021 to 2028, further underscoring the pivotal role that metal mesh screens play in enhancing operational efficiency and product safety. As industries continue to evolve, understanding the diverse applications and benefits of metal mesh screens is crucial for optimizing design and functionality in various settings.

What is a Metal Mesh Screen: Definition and Composition

A metal mesh screen is a versatile material fabricated from woven or welded strands of metal, typically stainless steel, aluminum, or carbon steel. These screens consist of a grid-like structure, where the openings can vary in size and shape depending on the application requirements. The composition of a metal mesh screen not only provides strength and durability but also allows for different levels of airflow and filtration according to the specific needs of various industries.

The manufacturing process involves weaving or welding wires together to create a robust matrix. The thickness and gauge of the metal used can influence the screen's performance, including its resistance to corrosion, its weight, and its ability to withstand high temperatures. Metal mesh screens can be treated or coated with additional materials to enhance their properties, achieving desired outcomes such as increased chemical resistance or improved aesthetics. This adaptable structure enables the screens to function effectively in a range of applications, from industrial filtration systems to architectural design elements, ultimately serving critical roles in enhancing safety, efficiency, and functionality.

Applications of Metal Mesh Screens

This bar chart illustrates the various applications of metal mesh screens in different industries, showcasing their versatility and importance.

Types of Metal Mesh Screens: Material Variations and Features

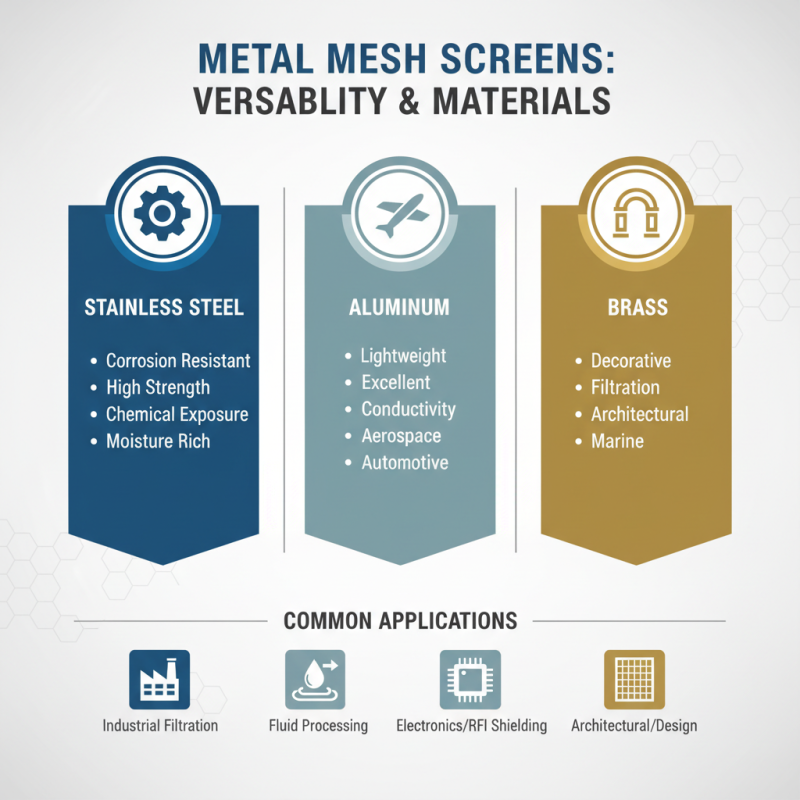

Metal mesh screens are versatile materials used across various industries, primarily distinguished by their construction material and specific features. Commonly utilized materials for these screens include stainless steel, aluminum, and brass, each of which offers unique benefits depending on the application. Stainless steel screens are favored for their corrosion resistance and strength, making them ideal for environments exposed to moisture or chemicals. Aluminum mesh, on the other hand, is lightweight and offers excellent conductivity, often being used in applications where weight is a concern, such as in aerospace and automotive industries.

Additionally, the features of metal mesh screens can vary significantly based on open area percentage and weave patterns. Screens with a high open area allow for better airflow and fluid passage, beneficial in filtration applications where efficiency is paramount. Meanwhile, certain weave types, such as plain weave, twill weave, or dutch weave, increase the screen's structural integrity or offer finer filtration capabilities. These variations allow designers and engineers to select specific metal mesh screens tailored to the performance requirements of their projects, whether for industrial machines, architectural applications, or safety barriers.

Applications of Metal Mesh Screens in Industrial Settings

Metal mesh screens are versatile components widely utilized in various industrial settings, primarily due to their strength, durability, and the ability to be customized for specific applications. In manufacturing environments, these screens serve as filters, separating fine particles from liquids or gases, thus ensuring that processes run smoothly and efficiently. For instance, in the food and beverage industry, metal mesh screens are often employed to filter out impurities during production, ensuring product quality and safety.

In construction and mining, metal mesh screens play a vital role in sifting materials. They are designed to withstand heavy loads and harsh conditions while providing effective separation of coarse from fine aggregates. This function is crucial for ensuring that the materials used in construction meet structural integrity requirements. Moreover, metal mesh screens are increasingly used in environmental applications, such as in wastewater treatment plants, where they help in removing solid contaminants from liquids, contributing to a cleaner and safer ecosystem. These applications showcase the essential role of metal mesh screens across diverse industrial sectors, enhancing efficiency and maintaining quality standards.

Advantages of Using Metal Mesh Screens in Architectural Design

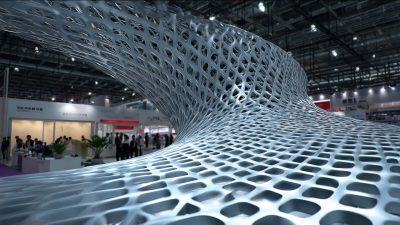

Metal mesh screens have gained significant popularity in architectural design due to their numerous advantages. One of the primary benefits is their versatility. These screens can be easily customized in terms of size, shape, and material, allowing architects to create unique designs that align with their creative visions. The ability to manipulate light and shadow through the screen also adds an aesthetic dimension to buildings, as natural light filters through while maintaining privacy and reducing glare.

In addition to their design flexibility, metal mesh screens offer durability and maintenance advantages. Made from resilient materials such as stainless steel or aluminum, they withstand various weather conditions and resist corrosion, making them ideal for both indoor and outdoor applications. This durability translates into lower maintenance costs over time, which is an appealing factor for both architects and building owners. Furthermore, metal mesh screens contribute to energy efficiency by promoting ventilation and cooling, effectively reducing reliance on artificial climate control systems. This combination of aesthetic appeal, durability, and functionality makes metal mesh screens an attractive option in modern architectural design.

What is a Metal Mesh Screen and How is it Used in Different Applications - Advantages of Using Metal Mesh Screens in Architectural Design

| Application | Type of Metal Mesh | Key Advantages | Common Materials Used |

|---|---|---|---|

| Architectural Facades | Perforated Metal Mesh | Aesthetic versatility, lightness, durability | Aluminum, Stainless Steel |

| Safety Screens | Welded Wire Mesh | High strength, impact resistance | Steel, Galvanized Steel |

| Ventilation Grilles | Expanded Metal Mesh | Excellent airflow, lightweight | Aluminum, Steel |

| Railings and Partitions | Chain Link Mesh | Lightweight, cost-effective | Galvanized Steel, Vinyl Coated Wire |

Future Trends in Metal Mesh Screen Technology and Usage

The future trends in metal mesh screen technology signal a shift toward enhanced durability, versatility, and sustainability. Advances in materials science are leading to the development of lighter yet stronger alloys, which improve performance while reducing environmental impact. This evolution allows metal mesh screens to be utilized in a broader range of applications, from architectural designs to filtration systems in various industries. As the demand for eco-friendly solutions grows, manufacturers are increasingly incorporating recyclable materials into their products, paving the way for more sustainable options in the marketplace.

Tips: When selecting a metal mesh screen for your project, consider the specific requirements such as mesh size, material strength, and resistance to corrosion. Conducting thorough research on the latest technology can help you make informed choices.

Another trend impacting metal mesh screens involves smart technology integration. The incorporation of sensors and smart monitoring systems can enhance their functionality, allowing for real-time data collection and analysis. This innovation is particularly beneficial in industries such as construction and agriculture, where monitoring conditions can lead to increased efficiency and improved safety. As innovation continues, we can expect metal mesh screens to evolve further, offering new solutions that meet the dynamic needs of various sectors.

Tips: Stay updated on industry trends and advancements in mesh technology to ensure you are utilizing the most effective materials for your specific needs, benefiting both performance and sustainability.

Related Posts

-

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025

-

Exploring the Benefits of Steel Mesh: The Ultimate Guide for Builders and DIY Enthusiasts

-

Why You Should Choose Galvanized Wire Mesh for Your Next Project

-

Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

-

Why Choosing the Right Stainless Steel Manufacturers Matters for Your Projects

-

Why You Should Choose Wire Cloth for Your Industrial Filter Needs