What is Stainless Steel Mesh and Its Applications?

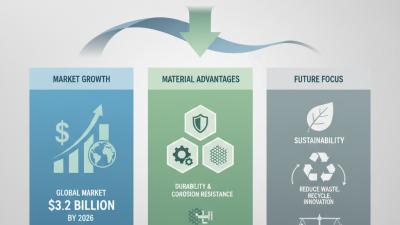

Stainless steel mesh is an essential product used across various industries. Its versatility and strength make it a popular choice. According to a 2022 market report by Smith & Associates, the stainless steel mesh industry is projected to grow by 5% annually. This growth is driven by increased demand in construction, food processing, and filtration applications.

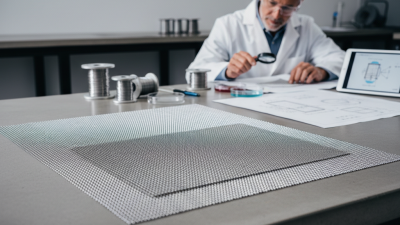

Dr. Emily Thompson, an expert in materials science, states, "Stainless steel mesh is crucial for modern engineering solutions." Her insights highlight the mesh's role in enhancing structural integrity and safety. However, this demand raises questions about sustainability. As production scales up, environmental impacts must be reviewed.

The applications of stainless steel mesh are diverse. It's often seen in architectural designs, industrial sieves, and safety barriers. Yet, there can be challenges in sourcing ethically produced materials. There's a need for a shift towards sustainable practices. Balancing industrial demand with eco-friendly methods is a critical consideration for the future of stainless steel mesh.

What is Stainless Steel Mesh?

Stainless steel mesh is a versatile material widely used across various industries. Composed of fine stainless steel wires, it forms a robust, durable screen. This type of mesh can resist rust and corrosion effectively, making it ideal for outdoor applications. Manufacturers often produce it in different sizes and weaves. This variety allows for customized solutions tailored to specific needs.

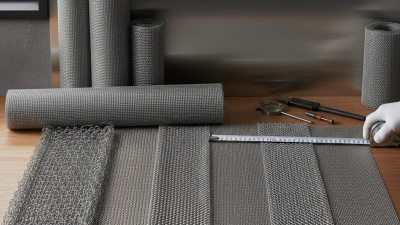

The applications of stainless steel mesh are broad. In construction, it provides support for plaster and as a reinforcement material. In the food industry, it serves as filters and screens, ensuring hygiene and quality. Additionally, it’s used in architectural designs for decorative elements or security features. However, the cost can be a factor for some businesses, limiting its adoption in small-scale projects.

When considering stainless steel mesh, reflect on your specific needs. Do the benefits outweigh the investment? Sometimes, alternatives might offer lower costs. Yet, quality and longevity are crucial in choosing the right material. Proper consideration will lead to better outcomes in your projects.

Composition and Types of Stainless Steel Mesh

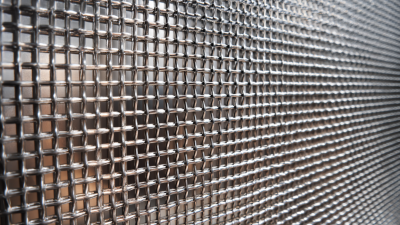

Stainless steel mesh is a versatile material used in various industries. Its composition typically includes chromium and nickel, providing excellent corrosion resistance. The mesh can come in different grades, impacting its durability and applications. Common grades include 304 and 316, each serving unique needs.

There are several types of stainless steel mesh. Woven mesh is one of the most popular. It is made by interlacing wires and is widely used in filtration and protection. Another type is welded mesh, where wires are fused at intersections. This type is commonly found in construction and security applications. Some users may find the choice overwhelming. Selecting the right type depends on specific needs and environments.

The applications of stainless steel mesh are vast. It is used in architectural design, food processing, and even medical devices. In some cases, installation may present challenges. Incorrect mesh selection can lead to problems down the line. It is essential to carefully consider your project requirements and usage.

Key Properties of Stainless Steel Mesh

Stainless steel mesh boasts excellent corrosion resistance. This property makes it suitable for various industries. Reports indicate that stainless steel mesh can endure extreme environments. For example, it resists rust when exposed to moisture and chemicals. This feature is crucial in food processing, where hygiene is paramount.

Another key property is its strength. Stainless steel mesh offers high tensile strength, allowing it to withstand significant pressure. Studies show that the tensile strength of stainless steel can range between 500 to 800 MPa. This strength makes it ideal for filtration applications. It can effectively filter out both solid and liquid contaminants.

Additionally, stainless steel mesh is versatile. It can be customized for different applications. For instance, the mesh opening size can vary from 1 mm to 100 mm, depending on the needs. This flexibility often leads to suboptimal designs. Some clients may overlook the importance of opening size in specific applications. Detailed analysis is needed to ensure the right choice.

What is Stainless Steel Mesh and Its Applications? - Key Properties of Stainless Steel Mesh

| Property | Description | Common Applications |

|---|---|---|

| Corrosion Resistance | Stainless steel mesh is highly resistant to rust and corrosion, making it suitable for harsh environments. | Food processing, chemical industries, marine applications |

| Durability | The material is strong and withstands wear and tear over time. | Construction, industrial filtration |

| Versatility | Can be manufactured in various types, sizes, and shapes for multiple uses. | Architectural applications, custom mesh designs |

| Aesthetic Appeal | Provides a sleek and modern appearance, suitable for design applications. | Interior design, decorative panels |

| Ease of Maintenance | Simple to clean and maintain, retaining its appearance over time. | Medical instruments, kitchenware |

Common Applications of Stainless Steel Mesh

Stainless steel mesh is versatile and used in various fields. One common application is in food processing. The mesh provides effective filtration. It’s used to separate solids from liquids. This ensures the purity of the food products. Additionally, stainless steel mesh is easy to clean, which is essential in maintaining hygiene.

In construction, stainless steel mesh serves multiple purposes. It acts as reinforcement in concrete. The mesh improves structural integrity and durability. Builders often use it for safety screens. It prevents debris from falling during construction. In another interesting application, it’s utilized in architectural designs. The mesh adds an aesthetic touch to facades and interiors.

Stainless steel mesh finds its place in industries like automotive and aerospace too. It is often used in air filters and strainers. These applications highlight its role in enhancing efficiency. However, it’s important to note its cost can be higher compared to other materials. Not everyone can afford it. This raises questions about its practicality in certain projects.

Advantages of Using Stainless Steel Mesh in Various Industries

Stainless steel mesh is gaining traction across various industries due to its numerous advantages. One significant benefit is its resistance to corrosion. According to a report by the International Stainless Steel Forum, stainless steel accounts for over 70% of the market for materials used in harsh environments. This durability extends the lifespan of equipment and reduces the need for frequent replacements.

In the food and beverage sector, stainless steel mesh is vital. It meets strict hygiene standards and withstands high temperatures. A study from Food Protection Trends revealed that using stainless steel nets in food processing reduces contamination risks. This is crucial for companies aiming to maintain product quality while maximizing efficiency.

Furthermore, the use of stainless steel mesh in construction provides additional benefits. It offers excellent strength-to-weight ratios. This can improve structural integrity while minimizing weight. However, some sectors still face challenges in adopting this material. Costs can be higher than traditional options. Companies must weigh these factors carefully. Ultimately, stainless steel's advantages often lead to long-term savings and enhanced performance.

Related Posts

-

10 Best Stainless Steel Mesh Options for Versatile Applications

-

Why Stainless Steel Mesh Screens Are Essential for Your Home and Industry Needs

-

2025 How to Choose the Best Stainless Steel Mesh Screen for Your Needs

-

Essential Tips for Choosing the Right Stainless Steel Mesh for Your Project

-

Top 10 Best Stainless Steel Wire Mesh Options for Your Projects?

-

2026 Top Trends in Stainless Steel Wire Mesh Applications?