What is a Stainless Steel Supplier and How to Choose the Right One

When it comes to sourcing high-quality materials for construction, manufacturing, and various industrial applications, selecting the right stainless steel supplier is crucial. Stainless steel has become a preferred choice across multiple sectors due to its durability, corrosion resistance, and aesthetic appeal. However, with a multitude of suppliers available, understanding how to identify the best one that aligns with your specific needs is essential.

In this guide, we will explore what constitutes a reliable stainless steel supplier. We will delve into key factors such as product quality, range of services, customer support, and pricing that can significantly influence your decision-making process. By breaking down these aspects, we aim to equip you with the knowledge necessary to make informed choices, ensuring that your investment in stainless steel products meets both your operational requirements and quality standards. Ultimately, choosing the right stainless steel supplier plays a pivotal role in the success of your projects and the maintenance of your business's efficiency.

Understanding the Role of a Stainless Steel Supplier in the Industry

Understanding the role of a stainless steel supplier in the industry is crucial for businesses seeking reliable materials for their manufacturing processes. Suppliers act as intermediaries between raw material producers and end-users, offering not only the steel itself but also valuable market insights and guidance. They play a vital role in navigating the complexities of the global supply chain, which can be affected by factors such as geopolitical tensions and trade tariffs. As seen with recent disruptions, these influences can significantly impact pricing and availability, which makes it essential for businesses to choose suppliers who can effectively manage these challenges.

When selecting a stainless steel supplier, it is important to assess their capacity to provide consistent quality and timely delivery. A reputable supplier should possess a deep understanding of market trends and pricing benchmarks, helping clients make informed decisions. Additionally, suppliers that actively engage in monitoring regulatory developments, such as anti-dumping investigations and tariffs, can better protect their clients from sudden price fluctuations and ensure a stable supply of materials. Ultimately, the right supplier will not only meet material needs but also contribute to the resilience and sustainability of a business's supply chain in a competitive landscape.

Key Specifications and Standards to Consider When Choosing a Supplier

When selecting a stainless steel supplier, it is crucial to consider key specifications and industry standards that ensure the quality and reliability of the materials. One primary factor is compliance with ASTM (American Society for Testing and Materials) standards, which dictate the mechanical and chemical properties of stainless steel. For example, a reputable supplier should provide materials that meet ASTM A240 for stainless steel sheets and plates, ensuring a minimum level of corrosion resistance and mechanical integrity. Additionally, certifications such as ISO 9001 can signal a supplier's commitment to consistent quality management processes, which is vital for long-term partnerships.

Another critical consideration is sustainability in sourcing practices. Recent research highlights the importance of integrating sustainability criteria into supplier selection, particularly in industries such as pharmaceuticals, where supply chain transparency can significantly impact inventory management. Suppliers that utilize an integrated decision-making framework, such as fuzzy TOPSIS and GRA, can provide clearer evaluations based on sustainability metrics. This approach not only addresses environmental concerns but also improves supplier reliability and performance. As the market shifts towards more ethical sourcing, stainless steel suppliers that prioritize these criteria are likely to remain competitive and meet the evolving demands of industries around the world.

Stainless Steel Supplier Comparison: Key Specifications

Evaluating Supplier Credentials: Certifications, Experience, and Reputation

When selecting a stainless steel supplier, evaluating their credentials is crucial. Key factors to consider include

certifications, experience, and reputation. Certifications are indicators of quality and compliance with industry standards.

Suppliers with recognized certifications, such as ISO 9001, demonstrate a commitment to maintaining high-quality processes and products.

It's essential to verify these certifications and understand what they entail to ensure the supplier meets the necessary requirements for your specific applications.

Experience in the industry also plays a significant role in supplier selection. A supplier with a long-standing presence in the market is likely to have gained valuable insights and expertise.

They will be better equipped to provide reliable advice, tailored solutions, and handle any potential challenges effectively. Furthermore, examining a supplier's reputation through customer reviews and case studies

can provide a clearer picture of their reliability and service quality. Engaging with current or past clients can reveal how the supplier performs under different circumstances,

helping you make an informed decision.

Analyzing Pricing Structures: Cost-Effectiveness and Value for Stainless Steel Materials

When choosing a stainless steel supplier, understanding pricing structures is crucial to assess cost-effectiveness and value. The global stainless steel market is evolving, with major production centers in Asia and varying trade barriers affecting accessibility. The demand for stainless steel is expected to grow significantly, with projections indicating a market value increase from USD 134.3 billion in 2025 to USD 173.6 billion by 2035. This growth can influence pricing strategies and supply chain dynamics based on raw material availability, especially Nickel Pig Iron (NPI), which is essential in stainless steel production.

Tips: When evaluating suppliers, consider the total cost of ownership, which includes transportation, quality assurance, and potential tariffs. A deeper understanding of the supplier's sourcing strategies—especially regarding NPI and chrome ore—can also provide insights into their pricing flexibility. Additionally, always compare quotes from multiple suppliers to ensure you're receiving a competitive rate that reflects current market trends.

Logistics and Supply Chain Management: Ensuring Timely Delivery of Products

Logistics and supply chain management play a crucial role in ensuring the timely delivery of products, especially in industries such as food, e-commerce, and chemicals. A staggering 30% of food produced for human use is wasted or lost along the supply chain annually, highlighting the urgent need for effective supply chain strategies. In 2025, optimizing supply chains, particularly in critical sectors like food and chemicals, will be essential for minimizing waste and enhancing overall efficiency.

E-commerce logistics is revolutionizing how goods are delivered from manufacturers to consumers, with a focus on streamlining the fulfillment of online orders. The complexity of these logistics requires robust management to address challenges such as inventory control, order accuracy, and speed of delivery. Real-time monitoring enabled by IoT technology can significantly enhance supply chain efficiency, offering predictive analytics and automation that are critical for meeting customer demands rapidly. As companies continue to adapt to changes and challenges within supply chains, integrating advanced solutions will be key in navigating the complexities of modern logistics.

Related Posts

-

The Ultimate Guide to Choosing the Right Stainless Steel Supplier for Your Projects

-

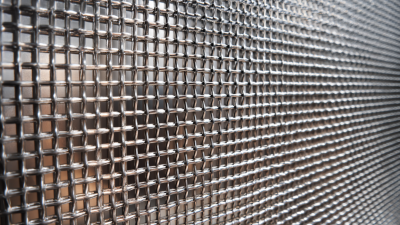

Why Stainless Steel Mesh Screens Are Essential for Your Home and Industry Needs

-

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

Discovering the Versatility and Durability of 304 Stainless Steel in Modern Applications

-

Understanding the Essential Role of Steel Rope in Everyday Applications