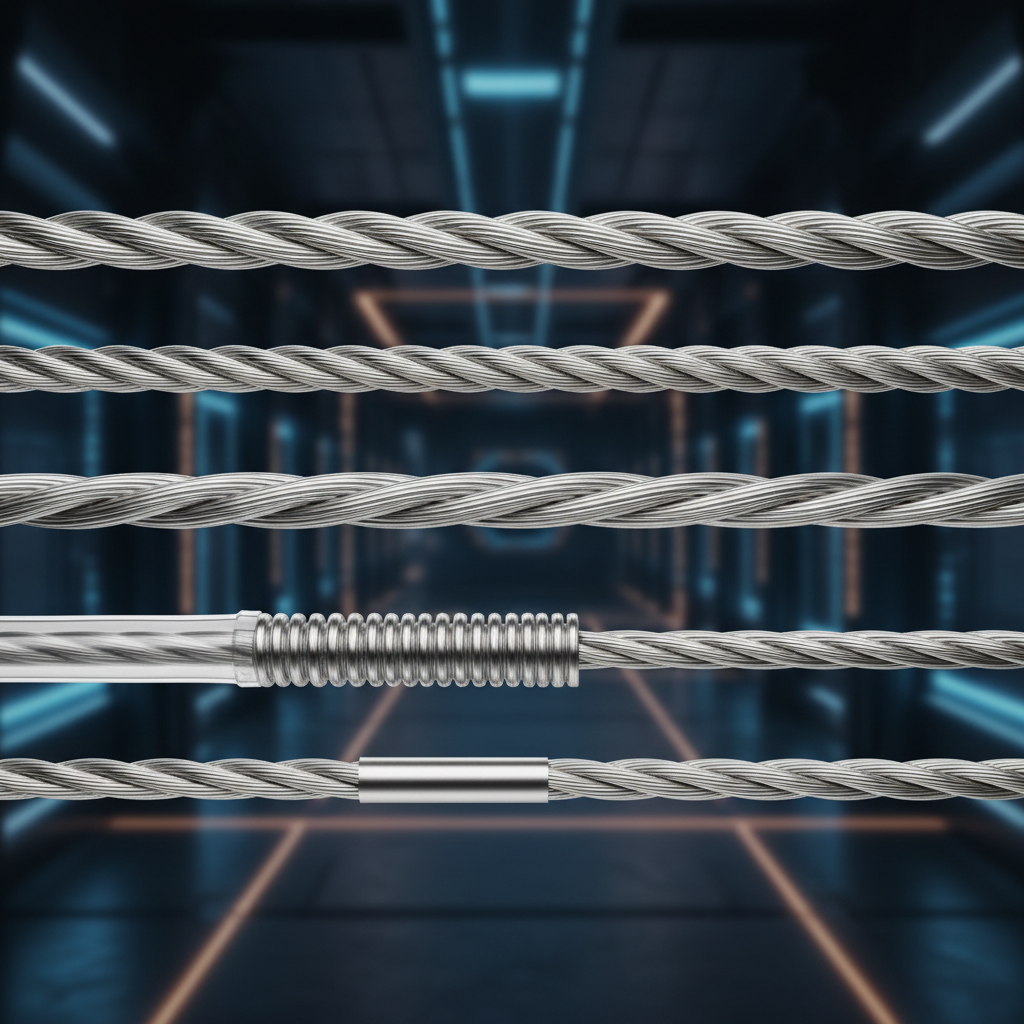

2025 Top 5 Stainless Steel Wire Rope Trends You Need to Know

As the demand for durable and versatile materials continues to rise across various industries, the stainless steel wire rope sector is poised for significant advancements in 2025. According to a recent market analysis by Research and Markets, the global stainless steel wire rope market is expected to grow at a compound annual growth rate (CAGR) of 5% from 2023 to 2030, driven by increased applications in construction, marine, and automotive sectors. This trend highlights the critical role that stainless steel wire ropes play in ensuring safety and efficiency in heavy-duty operations.

Industry expert Dr. John Blanchard, a noted authority in the wire rope manufacturing field, emphasizes the importance of innovation in this sector. He states, "The future of stainless steel wire rope lies in technological advancements that enhance its strength-to-weight ratio and corrosion resistance, making it an indispensable material for modern engineering solutions."

As we approach 2025, it is essential to understand the top trends shaping the future of stainless steel wire ropes, which not only reflect technological improvements but also align with sustainability goals and the evolving needs of various industries.

The Rise of Eco-Friendly Stainless Steel Wire Rope Production Techniques

The rise of eco-friendly stainless steel wire rope production techniques is becoming a defining trend in the industry. As global environmental awareness increases, manufacturers are seeking sustainable methods to reduce their carbon footprint. The global stainless steel wire market was valued at $54.6 billion in 2023, with projections indicating it will reach $173.1 billion by 2040, growing at a CAGR of 7.1% from 2024 onwards. This growth not only reflects increasing demand for stainless steel products but also highlights the industry's shift towards eco-friendly practices.

Innovative production techniques, such as recycling and optimizing resource use, are transforming how stainless steel wire ropes are manufactured. For instance, the adoption of naturally ventilated manufacturing facilities, like those proposed by Jakob Factory in Vietnam, represents a significant step towards sustainability. Such initiatives not only enhance energy efficiency but also minimize environmental impact. With the U.S. hot-dip galvanized steel market projected to grow from $17.36 billion in 2024 to $20.12 billion by 2026, the emphasis on sustainable production methods is likely to shape the future trajectory of the stainless steel wire rope sector.

Innovations in Coating Technologies for Enhanced Durability of Wire Ropes

The advancements in coating technologies have become crucial for enhancing the durability of stainless steel wire ropes. With the global plastic-coated wire ropes market projected to grow from USD 1.32 billion in 2025 to USD 1.78 billion by 2030, the demand for innovative coatings is apparent.

Various materials such as PVC, PE, and PP are being explored to improve the lifespan and performance of wire ropes, making them indispensable in sectors like automotive and aviation maintenance.

Research into electrical conductivity and durability has provided further insights into alternative coatings. For instance, the replacement of traditional insulating coatings, such as polyvinylpyrrolidone, showcases progress in material science that could also impact wire rope technology. As market reports indicate a CAGR of 6.2% for plastic-coated wire ropes, ongoing innovations promise to enhance not only the durability but also the performance of these essential components in extreme conditions. This trend marks an important evolution in ensuring the resilience and efficacy of steel wire ropes across diverse industries.

The Impact of Smart Technology on Stainless Steel Wire Rope Applications

The integration of smart technology into stainless steel wire rope applications is revolutionizing the industry, driving innovation and efficiency. As manufacturers seek to optimize production processes, intelligent welding techniques, such as laser welding with dynamic beam-shaping, are reducing waste and enhancing the quality of the ropes. This advancement not only minimizes the need for filler materials but also allows for more precise and versatile manufacturing methods.

Moreover, the incorporation of artificial intelligence is paving the way for improved safety and monitoring systems in wire rope applications. AI-powered vision systems can detect human movements within areas where wire ropes are utilized, significantly reducing the risk of accidents. These technologies transform traditional practices, enabling the industry to meet increasing demand while maintaining higher standards of safety and performance. The ongoing trends indicate that the future of stainless steel wire rope will be closely intertwined with advancements in smart technology, leading to a more efficient and safer operational landscape.

Trends in Stainless Steel Wire Rope Sizing and Customization for Industrial Needs

As industries advance, the demand for customized stainless steel wire ropes is on the rise, driven by specific industrial needs and innovative sizing trends. Businesses are increasingly recognizing the importance of tailoring wire ropes to fit unique operational requirements, whether for construction, marine applications, or telecommunications. This customization extends beyond mere sizing; it encompasses the type of coating, flexibility, and strength specifications that can significantly impact performance and durability.

Additionally, advancements in manufacturing processes have enabled fine-tuning of wire rope dimensions to adhere to stricter industry standards. Enhanced production techniques allow for greater precision in diameter and lay type, ensuring that the ropes can withstand the rigors of their respective environments while maintaining efficiency. With the ongoing evolution in the stainless steel wire rope market, industries can expect more robust, versatile, and tailored solutions that meet their specific operational challenges, ensuring safety and effectiveness in their applications.

2025 Top 5 Stainless Steel Wire Rope Trends You Need to Know

This chart illustrates the anticipated trends in stainless steel wire rope sizing and customization for industrial needs in 2025.

Market Demand Shifts: Key Sectors Driving Growth for Stainless Steel Wire Ropes in 2025

The demand for stainless steel wire ropes is anticipated to shift significantly in 2025, driven by various key sectors poised for growth. Industries such as construction, energy, and transportation are increasingly recognizing the advantages of stainless steel wire ropes, including their corrosion resistance and superior strength. This trend highlights a broader move towards durable and sustainable materials, which aligns with global efforts to improve infrastructure and enhance safety in engineering applications.

Additionally, the plastic-coated wire ropes segment is also gaining traction, attributed to their versatility and enhanced protective qualities. As sectors like automotive and marine transportation expand, the need for specialized wire rope solutions is intensifying. Companies are focusing on new innovations in coating types and material combinations to meet these changing demands. This multi-sectoral upswing indicates a robust market evolution, revealing significant opportunities for manufacturers and suppliers in the stainless steel wire rope industry.

2025 Top 5 Stainless Steel Wire Rope Trends You Need to Know

| Trend | Market Demand Driver | Key Sector | Projected Growth (%) | Notes |

|---|---|---|---|---|

| Increased Use in Construction | Infrastructure Development | Construction | 15% | Enhanced safety standards drive demand |

| Growth in Marine Applications | Rising Maritime Activities | Marine | 10% | Corrosion resistance is crucial in this sector |

| Adoption of Automation and Robotics | Technological Advancements | Manufacturing | 12% | Increased efficiency and precision required |

| Rising Demand in Renewable Energy | Shift Towards Sustainable Solutions | Energy | 20% | Wind and solar installations need durable materials |

| Focus on Maintenance-Free Solutions | Cost Reduction Initiatives | General Industry | 8% | Maintenance-free products attract cost-sensitive sectors |

Related Posts

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

Understanding the Essential Role of Steel Rope in Everyday Applications

-

Discovering the Versatility and Durability of 304 Stainless Steel in Modern Applications

-

Revitalize Your Cleaning Routine: Discover the Power of Steel Brushes for Every Task

-

Innovative Trends and Market Insights for Welded Wire Mesh at the 2025 China Import and Export Fair

-

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects