Top 10 Applications and Benefits of Steel Wire You Need to Know!

In the ever-evolving world of construction and manufacturing, steel wire stands out as a vital component that has transformed various industries. According to Dr. Emily Harrison, a renowned expert in materials engineering, "Steel wire is essential not just for its strength, but for its versatility, enabling innovative applications that drive progress." This statement underlines the profound impact that steel wire has across multiple sectors, from construction and automotive to telecommunications and aerospace.

The applications of steel wire are vast and varied, demonstrating its critical role in enhancing structural integrity and performance. Its flexibility, durability, and resistance to corrosion make it an ideal choice for numerous uses, whether it's in reinforcing concrete, producing high-tension cables, or crafting intricate wire products. As we delve into the top ten applications and benefits of steel wire, it becomes clear that this seemingly simple material is a cornerstone of modern engineering, enabling solutions that are both efficient and sustainable.

Applications of Steel Wire in Construction and Infrastructure

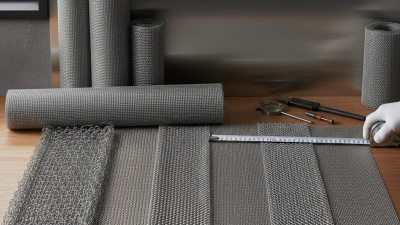

Steel wire plays a crucial role in the construction and infrastructure sectors, providing strength and durability to various applications. Its high tensile strength makes it an ideal material for reinforcing concrete, ensuring that structures can withstand significant loads and stress. In the construction of bridges, buildings, and tunnels, steel wire is often utilized in the form of rebar or wire mesh, enhancing the overall stability and longevity of these infrastructures. Additionally, steel wire is crucial in post-tensioning applications, which involves tensioning high-strength steel tendons to improve the load-carrying capacity of concrete elements.

Beyond structural reinforcement, steel wire is also employed in various other ways within the industry. It is extensively used for creating safety barriers and fencing, providing protection for construction sites and ensuring safety for workers and the public. Moreover, steel wire ropes are essential for lifting and hoisting heavy materials in construction, ensuring efficient and safe operations on site. The versatility and reliability of steel wire in such applications highlight its importance in modern construction practices, contributing significantly to the safety and efficiency of infrastructure development.

Benefits of Steel Wire in Manufacturing and Industry

Steel wire plays a crucial role in manufacturing and various industrial applications, owing to its strength, flexibility, and durability. One of the primary benefits of steel wire is its use in reinforcing concrete structures. When embedded in concrete, steel wire can significantly enhance tensile strength, ensuring that structures can withstand various stresses and loads. This composite functionality is vital for industries involved in construction and infrastructure development, where safety and longevity are paramount.

Additionally, steel wire is widely utilized in the production of diverse products such as cables, springs, and fasteners. Its ability to be drawn into thin strands without losing tensile strength makes it indispensable in these applications. In the automotive industry, for instance, steel wire components are critical for ensuring vehicle safety and performance. The versatility of steel wire also extends to its role in manufacturing wire mesh and fencing, offering security and durability for both residential and commercial properties. By integrating steel wire into their processes, manufacturers can leverage its properties to create more robust and resilient products, enhancing overall production efficiency and reliability.

Role of Steel Wire in Automotive and Aerospace Sectors

The role of steel wire in the automotive and aerospace sectors is pivotal due to its exceptional strength, flexibility, and resistance to fatigue. In the automotive industry, steel wire is used extensively in manufacturing reinforcement components such as springs, cables, and wires in safety systems. These applications not only enhance vehicle performance but also ensure passenger safety. The lightweight nature of steel wire allows for a reduction in overall vehicle weight, contributing to improved fuel efficiency and reduced emissions, which is increasingly important in today’s eco-conscious market.

In the aerospace sector, steel wire plays a critical role in the construction of aircraft and spacecraft. High-strength steel wire is utilized in rigging, hoisting systems, and various structural components that demand unparalleled tensile strength and durability under extreme conditions. The reliability of steel wire helps to maintain the integrity of structures subjected to high stress during takeoff, flight, and landing. Furthermore, advancements in alloy technology have led to the development of corrosion-resistant steel wires, enhancing longevity and safety in these applications where performance is non-negotiable.

Steel Wire in Telecommunications and Electrical Applications

Steel wire plays a crucial role in telecommunications and electrical applications, primarily due to its incredible strength, durability, and conductivity. According to a recent industry report, the demand for steel wire in telecommunications has increased by over 15% in the past five years, primarily driven by the expansion of fiber optic networks and the growing requirement for reliable infrastructure. Steel wire is used in the construction of overhead communication lines and other infrastructure, providing the necessary support for heavy loads while ensuring the integrity of the transmission.

Moreover, the electrical industry heavily relies on steel wire for its high conductivity and tensile strength. Data from the International Electrotechnical Commission indicates that more than 60% of high-voltage transmission lines are constructed using steel-reinforced aluminum wire, which combines the advantages of both materials, ensuring efficiency and safety in energy transfer. The versatility of steel wire enables it to be utilized in a variety of electrical applications, including grounding systems and electrical fencing, further enhancing its significance in maintaining reliable and safe power distribution systems.

Top 10 Applications of Steel Wire in Telecommunications and Electrical Applications

Innovations and Future Trends in Steel Wire Technology

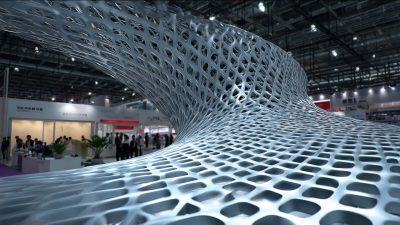

Innovations in steel wire technology are paving the way for enhanced performance and sustainability in various applications. One notable trend is the development of high-strength steel wires that offer improved durability without significantly increasing weight. This innovation is particularly beneficial in construction and automotive industries, where material efficiency is crucial. Additionally, smart steel wire technology that integrates sensors is gaining traction, allowing the monitoring of structural integrity in real-time. This not only enhances safety but also extends the lifespan of infrastructures, reducing maintenance costs.

Tips: When selecting steel wire for a project, consider the specific requirements such as tensile strength, corrosion resistance, and flexibility. Understanding the intended application can guide you in choosing the right type of wire, ultimately impacting the effectiveness and longevity of your project.

Another exciting advancement is the move towards eco-friendly steel production processes. Techniques that reduce carbon emissions and energy consumption during manufacturing are becoming more prevalent, aligning steel wire production with global sustainability goals. As industries increasingly prioritize environmental responsibility, these innovations not only support regulatory compliance but also appeal to a growing market of environmentally conscious consumers.

Tips: Stay informed about emerging technologies in steel wire production. Regularly researching and attending industry conferences can provide insights into the latest trends and best practices, ensuring your projects benefit from cutting-edge developments.

Top 10 Applications and Benefits of Steel Wire You Need to Know!

| Application | Benefits | Innovations | Future Trends |

|---|---|---|---|

| Construction | High tensile strength and durability | Usage of corrosion-resistant coatings | Increased automation in manufacturing |

| Automotive | Lightweight yet strong | Advanced welding techniques | Integration of smart materials |

| Electronics | Reliable conductivity | Thin wire technology developments | Greater miniaturization of components |

| Telecommunications | Effective transmission of signals | Stronger, lighter wire options | Fiber optic integration |

| Mining | Enhanced safety through structural support | High-strength wire ropes | Automation and robotics in mining operations |

| Aerospace | Weight reduction for fuel efficiency | Titanium wire advancements | Sustainable production methods |

| Agriculture | Durable fencing and supports | Bioresistant wire coatings | Smart farming wire solutions |

| Marine | Corrosion resistance in harsh environments | Innovative galvanization techniques | Integration with green technologies |

| Construction Supplies | Versatile applications in various structures | Recyclable and eco-friendly options | Circular economy approaches in manufacturing |

Related Posts

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

2025 How to Choose the Best Stainless Steel Mesh Screen for Your Needs

-

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025

-

Why You Should Choose Wire Cloth for Your Industrial Filter Needs

-

2025 Top 5 Stainless Steel Wire Rope Trends You Need to Know

-

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects