2026 Top Trends in Welding Wire Selection for Optimal Performance?

The welding wire industry is evolving rapidly. In 2026, selecting the right welding wire will be crucial for optimal performance. A report from the American Welding Society highlights that improper selection can lead to 30% inefficiencies in welding projects. Clients expect superior results, necessitating advancements in material technology and application techniques.

Expert John Smith, a welding engineer with over 20 years of experience, states, "Choosing the correct welding wire can make or break a project." This emphasizes the importance of understanding wire properties and compatibility with various welding processes. As automation and digital tools enhance the welding industry, wire selection must also advance.

There are many choices, and it can be overwhelming. With so many grades and types available, mistakes happen frequently. Companies need to reflect on their processes and prioritize expertise in this area. Ignoring these evolving trends may hinder progress and affect project outcomes significantly.

Key Factors Influencing Welding Wire Selection in 2026

Welding wire selection in 2026 is influenced by several key factors. One primary concern is the material composition. Data shows that materials like carbon steel account for over 40% of all recommended welding wires. Welding professionals are prioritizing wires with enhanced chemical and mechanical properties. These wires exhibit better performance in extreme conditions, making them essential for heavy industry applications.

Another significant factor is the advancement in welding technology. The global market for welding wire is projected to reach $22 billion by 2026. This growth is driven by improvements in automation and robotics. Such technologies demand high-quality welding wires that can keep pace. A study indicated that 25% of users experienced issues with wire feed consistency. This highlights the need for careful selection to avoid costly downtimes.

Environmental regulations also play a crucial role. Sustainable options, such as low-fume wires, are gaining traction. About 35% of welders reported a shift towards eco-friendly materials. These wires help reduce emissions and ensure compliance with regulations. However, not all eco-friendly options provide optimal performance. This creates a dilemma for welders when choosing the right product. The need for balance is evident.

Emerging Materials for Enhanced Welding Wire Performance

Welding wire selection is evolving. Emerging materials are paving the way for enhanced performance. Advanced alloys and composite wires offer unique benefits. According to a recent industry report, the use of nickel-based alloys can improve corrosion resistance by up to 30%. This makes them ideal for demanding environments.

Copper-infused wires are gaining traction as well. They provide better conductivity and lower heat transfer. This results in cleaner welds and reduced spatter. A study indicated a significant reduction in post-weld cleanup time when using these materials. However, they can be more expensive, and researchers are still exploring cost-effective solutions.

Tips: Always consider the application when selecting welding wire. Not all materials suit every project. Analyze the environment and conditions your welds will face to choose wisely.

Furthermore, while these new materials are promising, there are challenges. Compatibility with existing equipment is a concern too. Users need to ensure that their processes can adapt to these novel wires.

2026 Top Trends in Welding Wire Selection for Optimal Performance

| Trend | Description | Emerging Material | Performance Benefit |

|---|---|---|---|

| Advanced Alloy Composition | Utilizing new alloy mixtures to improve weld quality. | Nickel-Copper Alloys | Enhanced corrosion resistance and strength. |

| Eco-friendly Options | Development of welding wires with reduced environmental impact. | Bio-based Materials | Lower carbon footprint during production. |

| High-temperature Resistance | Wires capable of performing in extreme temperatures. | Inconel Alloys | Maintains mechanical properties under heat stress. |

| Precision Welding Technologies | Advancements in welding techniques requiring specialized wires. | Composite Wires | Improved accuracy and control in welding processes. |

| Self-Fluxing Wires | Wires that reduce or eliminate the need for additional flux. | Fluoride-based Coatings | Saves time and improves cleanliness of welds. |

Technological Innovations in Welding Wire Manufacturing

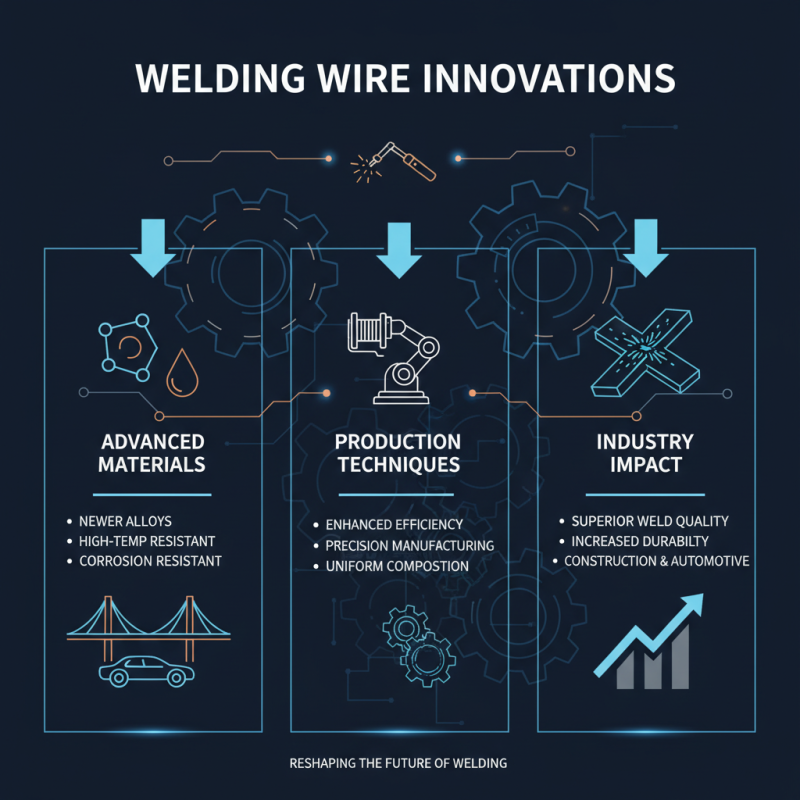

Innovations in welding wire manufacturing are reshaping the industry. Advanced materials and production techniques enhance performance and efficiency. These changes lead to better weld quality and durability. For instance, newer alloys can withstand higher temperatures and corrosive environments. This is essential in sectors like construction and automotive.

When selecting welding wires, consider compatibility with your project. Use wires that match the base materials. Different materials require specific wire compositions. This can prevent failures during the welding process.

**Tips:** Always test your welds before full-scale operations. Monitor for defects early on. Additionally, stay updated on new technologies. Welding advancements appear frequently, improving safety and efficiency. Remain open to adapting your techniques and materials to meet evolving standards.

Environmental Considerations in Welding Wire Selection

In recent years, environmental considerations have become paramount in welding wire selection. The industry has seen a shift toward materials that minimize harmful emissions. Reports indicate that nearly 35% of welding companies now prioritize environmentally friendly practices. This is not merely a trend; it is a necessity.

Many welding wires release fumes during the process, impacting air quality and worker health. According to the American Welding Society, toxic fumes can reduce lung function and lead to long-term occupational hazards. For this reason, choosing low-fume welding wires can significantly enhance workplace safety. Opting for wires with low alloy content or those that use inert gases can mitigate these harmful effects.

Furthermore, disposal practices of welding consumables pose a significant environmental challenge. About 25% of welding waste is improperly disposed of, impacting soil and water sources. Promoting the use of recyclable materials in welding wires can help reduce this waste. However, not all recycled wires deliver optimal performance. Striking a balance between sustainability and performance remains a challenge the industry must confront.

Industry-Specific Trends in Welding Wire Applications

In 2026, the welding wire industry is focusing on specific trends tailored to various applications.

Automotive manufacturing is leaning towards wires that enhance speed and efficiency. Lightweight materials are becoming popular, leading to a shift in wire selection. Welders now prefer wires that work well with aluminum and composites. This trend is crucial for meeting strict industry standards and fuel efficiency demands.

In construction, there is a growing need for wires that offer superior corrosion resistance. Infrastructure projects require durable materials to withstand harsh environments. Welders are experimenting with new coatings to improve longevity.

However, some may overlook the balance between performance and cost. A low-cost wire may lead to frequent replacements.

The shipbuilding sector seeks wires that provide excellent mechanical properties. It is essential for safety and longevity at sea. Yet, determining the right wire can be challenging.

Welding conditions vary greatly, and selecting a one-size-fits-all approach may not yield optimal results. Continuous innovation and research are necessary to navigate these complexities and refine welding wire selections.

Related Posts

-

Top 10 Welding Wire Types You Need to Know for Your Next Project

-

10 Essential Tips for Using a Wire Brush Effectively in Your Projects

-

Top Uses of Steel Cable in Everyday Applications How Does It Work?

-

Ultimate Tube Brush Tips for Cleaning Hard to Reach Areas?

-

Top 10 Best Stainless Steel Wire Mesh Options for Your Projects?

-

What is a Stainless Steel Supplier and How to Choose the Right One