Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

When it comes to effective cleaning and maintenance, the wire brush stands out as a versatile and indispensable tool in various settings. Whether you are tackling heavy-duty rust removal on metal surfaces, prepping materials for painting, or simply cleaning up a workshop, wire brushes offer the durability and efficiency needed for a range of tasks. Their unique bristle construction allows for scraping, scrubbing, and polishing, making them an ideal choice for both professional tradespeople and DIY enthusiasts alike.

Understanding the best applications for wire brushes can significantly enhance your cleaning and maintenance routine. From removing stubborn debris to preparing surfaces for sealing or coatings, knowing how to utilize this tool effectively can save time and effort. In this guide, we will explore the top uses for wire brushes, providing essential tips to maximize their potential while ensuring safety and precision in your projects. Embracing the wire brush in your toolkit not only streamlines your tasks but also contributes to the longevity of your tools and materials, ultimately leading to better results in your endeavors.

Types of Wire Brushes and Their Specific Uses

Wire brushes are versatile tools utilized in various cleaning and maintenance tasks. Understanding the different types of wire brushes and their specific applications can enhance their effectiveness and extend the life of the tools and surfaces involved.

Twisted wire brushes are ideal for heavy-duty tasks, such as removing rust and corrosion from metal surfaces. Their robust bristles can tackle stubborn debris efficiently, making them perfect for industrial environments. On the other hand, crimped wire brushes are better suited for lighter cleaning tasks. They offer a softer touch while still effectively removing paint, dirt, or other contaminants from delicate surfaces like wood or softer metals. When choosing a wire brush, consider the material you are working on and the level of abrasiveness required.

**Tips:** Always select the appropriate wire brush for your specific task to avoid damaging the surface. Additionally, wearing protective gear, such as gloves and goggles, is crucial to protect yourself from brush bristles and debris. Lastly, regularly inspect your wire brushes for wear and replace them as needed to maintain their cleaning efficiency. Proper maintenance not only ensures better performance but also prolongs the life of your tools.

Techniques for Using Wire Brushes Effectively

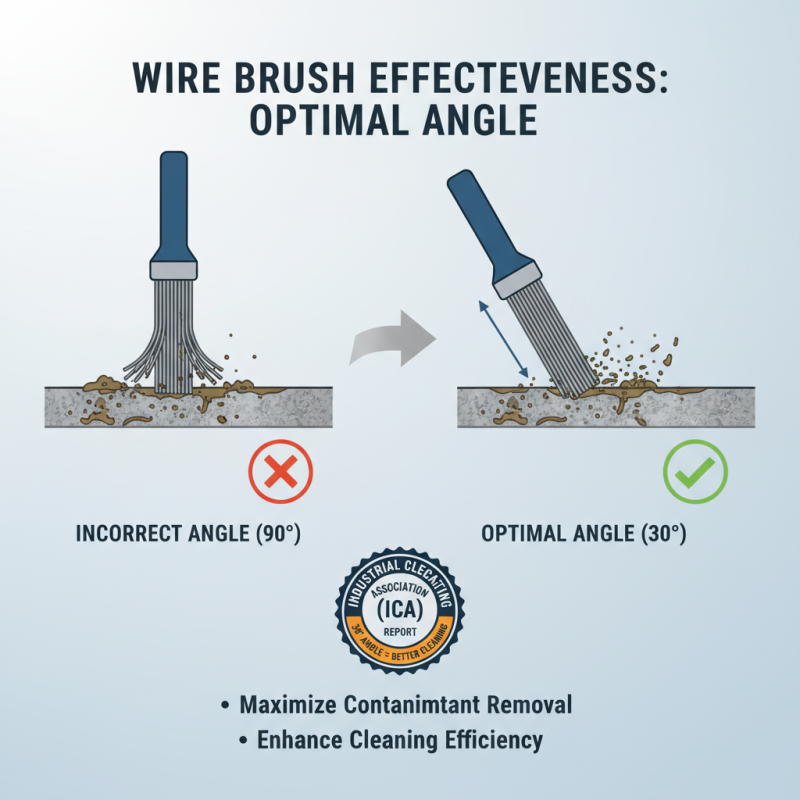

Wire brushes are essential tools for various cleaning and maintenance tasks across multiple industries. To maximize their effectiveness, employing the right techniques is crucial. For instance, maintaining the optimal angle while using a wire brush can significantly enhance cleaning efficiency. According to a report from the Industrial Cleaning Association (ICA), using the brush at a 30-degree angle allows for better penetration of bristles into surfaces, leading to a more thorough removal of contaminants.

In addition, the choice of bristle material should align with the specific application at hand. Metal bristles are effective for heavy-duty cleaning tasks, such as removing rust or scale, while softer materials, like nylon, are suited for delicate surfaces. The World Industrial Cleaning Market Report highlights that a staggering 60% of cleaning professionals noted improvements in project outcomes when selecting the right bristle type for their tasks. Moreover, it's vital to apply even pressure throughout the cleaning process to avoid damaging the surface, which can be a common pitfall for inexperienced users. Adopting these techniques not only improves cleaning results but also extends the lifespan of the wire brush, making it a cost-effective choice for organizations.

Safety Precautions When Handling Wire Brushes

When working with wire brushes, safety should be the primary concern. The bristles of wire brushes can easily become dislodged during use, posing a hazard to the user and those nearby. To minimize risks, it is essential to wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and a dust mask. These items help to protect against flying debris and fine particles generated during the cleaning process. Additionally, users should consider wearing long sleeves and trousers to further shield their skin from potential scratches or cuts.

Proper handling techniques are also crucial in ensuring safety when using wire brushes. Always grasp the tool firmly and avoid excessive pressure, which can lead to bristle breakage. It’s advisable to work at a controlled speed and avoid using the brush at steep angles to prevent the bristles from dislodging or causing slip-related accidents. Regularly inspecting the wire brush for signs of wear or damage is important; if you notice any fraying or loosening of the bristles, it’s time to replace the tool. By adhering to these safety precautions, you can effectively mitigate the risks associated with wire brush use and maintain a safe work environment.

Maintenance Tips to Extend the Life of Wire Brushes

Proper maintenance of wire brushes is crucial for maximizing their lifespan and effectiveness in cleaning and maintenance tasks. One of the key tips is to clean the bristles after each use. Residual debris can become embedded in the brush, leading to reduced efficiency and potential damage to surfaces during future cleaning. A simple method is to use another brush or a toothpick to remove any stubborn particles lodged in the wire. Regularly inspecting the bristles for wear and tear can also help you determine when it’s time to replace the brush.

Additionally, storing wire brushes correctly can significantly extend their life. Keeping them in a dry place away from moisture is essential to prevent rust and corrosion. If the wire brush is stored in a toolbox or drawer alongside other tools, consider using a protective cover or pouch to avoid snagging the bristles on sharp edges. Lastly, after prolonged use or exposure, applying a light coat of oil can help protect the bristles and maintain their flexibility, ensuring the brush remains effective for a longer period. Implementing these maintenance tips will ensure that your wire brushes remain a reliable tool for various cleaning and maintenance jobs.

Common Applications in Various Industries and DIY Projects

Wire brushes are indispensable tools in a variety of industries due to their effectiveness in cleaning and maintenance tasks. In automotive and manufacturing sectors, wire brushes are frequently used to remove rust, paint, and other contaminants from metal surfaces, preparing them for refinishing or welding. Their durable bristles are capable of reaching into crevices and corners that other cleaning tools cannot, ensuring a thorough clean. This is particularly important in environments where precision and cleanliness are critical, such as in the production of machinery or vehicle parts.

In the realm of DIY projects, wire brushes find their utility in woodworking and home improvement tasks. They can be employed to clean surfaces prior to staining or sealing, allowing for better adhesion and a smoother finish. Additionally, wire brushes are effective for restoring old furniture by stripping away layers of paint or varnish, revealing the natural beauty of the wood beneath. Whether used on metal or wood, wire brushes are versatile and effective, making them a go-to choice for both professionals and hobbyists in various applications.

Related Posts

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Revitalize Your Cleaning Routine: Discover the Power of Steel Brushes for Every Task

-

Top Wire Brush Types to Choose for Effective Cleaning in 2025

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

10 Best Stainless Steel Mesh Options for Versatile Applications

-

Exploring the Versatility of Stainless Steel Wire: Applications in Everyday Life and Industry