Top 10 Wire Brush Drill Attachments for Efficient Cleaning and Stripping

In the realm of power tools, the wire brush drill attachment stands out as an essential accessory for both professionals and DIY enthusiasts alike. These attachments not only enhance the efficiency of the cleaning process but also offer superior stripping capabilities for various surfaces. According to John Richards, a leading expert in power tool accessories, "A high-quality wire brush drill attachment can transform your drill into a versatile cleaning machine, tackling tough jobs with ease."

As more people turn to wire brush drill attachments for their robustness and effectiveness, it's vital to understand the diverse options available in the market. From coarse brushes designed for heavy-duty stripping to finer options suitable for delicate surfaces, each type serves a specific purpose. This article will delve into the top 10 wire brush drill attachments that not only promise exceptional cleaning and stripping performance but also provide insight into their best applications. Whether you're a contractor dealing with heavy build-up or a homeowner maintaining your property, choosing the right wire brush drill attachment can make all the difference in achieving pristine results.

Understanding Wire Brush Drill Attachments and Their Applications

Wire brush drill attachments are versatile tools designed for a variety of cleaning and stripping tasks. These attachments are crafted from durable metal bristles, which effectively remove rust, paint, and other debris from metal surfaces. Their design allows for compatibility with standard drills, making them an accessible option for both professional tradespeople and DIY enthusiasts. By simply attaching a wire brush to a drill, users can significantly reduce the time and effort required for surface preparation, contributing to a more efficient workflow.

The applications of wire brush drill attachments are diverse, ranging from automotive repairs to household projects. In automotive maintenance, they are ideal for cleaning engine parts or removing old paint from surfaces before refinishing. For home improvement tasks, wire brushes can tackle grime and corrosion on metal fixtures, outdoor furniture, or tools previously exposed to the elements. Additionally, these attachments can be used in metalworking to prepare surfaces for welding or painting, ensuring better adhesion and a cleaner finish. Understanding the specific type of wire brush attachment will help users achieve optimal results based on their intended application.

Top 10 Wire Brush Drill Attachments for Efficient Cleaning and Stripping

| Attachment Type | Wire Material | Diameter (inches) | Application | Recommended RPM |

|---|---|---|---|---|

| Crimped Wire Brush | Steel | 2 | Rust Removal | 2000-3000 |

| Cup Brush | Brass | 3 | Surface Cleaning | 1800-2800 |

| End Brush | Stainless Steel | 1.5 | Detailing | 3000-4000 |

| Twist Knot Brush | Carbon Steel | 4 | Heavy Duty Cleaning | 1500-2300 |

| Wire Wheel Brush | Nickel Plated | 3.5 | Paint Stripping | 2000-3500 |

| Flat Wire Brush | Steel | 2.5 | Weld Cleaning | 2500-3200 |

| Diamond Brush | Ceramic | 2 | Concrete Cleaning | 2000-2700 |

| Mini Brush Attachment | Mixed Metal | 1 | Tight Spaces | 3000-4000 |

| Nylon Brush | Nylon | 2 | Surface Prepping | 1800-2500 |

| Buffing Brush | Soft Brass | 2 | Finishing | 1200-2000 |

Key Features to Look for in Wire Brush Drill Attachments

When selecting wire brush drill attachments for efficient cleaning and stripping, there are several key features to consider. First, the material of the brush bristles plays a crucial role in determining its effectiveness. Steel wire brushes are commonly used for heavy-duty tasks, while brass or nylon bristles are ideal for more delicate surfaces, preventing scratches while still offering good cleaning capabilities. The choice of material directly impacts the attachment's longevity and performance across various applications.

Another important aspect to examine is the size and shape of the brush attachment. Different tasks may require brushes of varying diameters or forms, such as cup or wheel shapes, to access tight spaces or cover larger areas efficiently. Additionally, look for attachments with a quick-change feature that allows for effortless swapping between different brushes without requiring additional tools. This not only saves time but also enhances productivity, making the cleaning tasks smoother and more efficient. Overall, choosing the right wire brush drill attachment involves carefully evaluating these features to ensure the best results in your cleaning and stripping projects.

Top 10 Recommended Wire Brush Drill Attachments for Cleaning

When it comes to efficient cleaning and stripping, wire brush drill attachments are indispensable tools for both DIY enthusiasts and professionals. These attachments come in various sizes and bristle types, making them suitable for a range of cleaning tasks such as rust removal, paint stripping, and surface preparation. Their versatility ensures that you can tackle everything from delicate surfaces to tougher materials with ease. Whether you're working on metal, wood, or masonry, choosing the right wire brush is key to achieving a clean and polished finish.

Tips for effective use of wire brush drill attachments include selecting the appropriate brush for your specific cleaning task. A finer bristle will work better on delicate surfaces, while a stiffer brush is ideal for more robust materials. Additionally, start at a low speed to prevent damage to the surface and gradually increase speed as needed. Always maintain a steady hand and avoid excessive pressure; letting the brush do the work will yield the best results without risking wear and tear on both the brush and the surface being cleaned.

Another important aspect to consider is safety. Always wear protective gear such as goggles and gloves, as wire bristles can detach during use and pose a risk of injury. Furthermore, check the attachment for any signs of wear before starting your work—this ensures that you are using a safe and effective tool. By following these tips, you can maximize the efficiency of your wire brush drill attachments and achieve impressive cleaning results.

Comparing the Efficiency of Different Wire Brush Attachments

When it comes to cleaning and stripping surfaces, wire brush drill attachments play a crucial role in enhancing efficiency. These attachments vary significantly in design, material, and bristle configuration, all of which influence their performance on different substrates.

For instance, attachments featuring crimped wire are adept at removing rust and stubborn paint from metal surfaces, while those with twisted wire tend to offer more durability and can tackle tougher jobs, making them suitable for heavy-duty applications.

Moreover, the efficiency of these wire brush attachments also hinges on factors such as the speed and power of the drill being used. Higher RPM drills can provide a more aggressive cleaning action, but they may also increase wear on the bristles. It's important to choose the right balance between the attachment type and the drill speed to achieve optimal results.

Additionally, understanding the specific cleaning needs—whether removing old paint from wood or preparing surfaces for welding—can guide users in selecting the most effective attachment type for their project, ultimately leading to better outcomes and time savings.

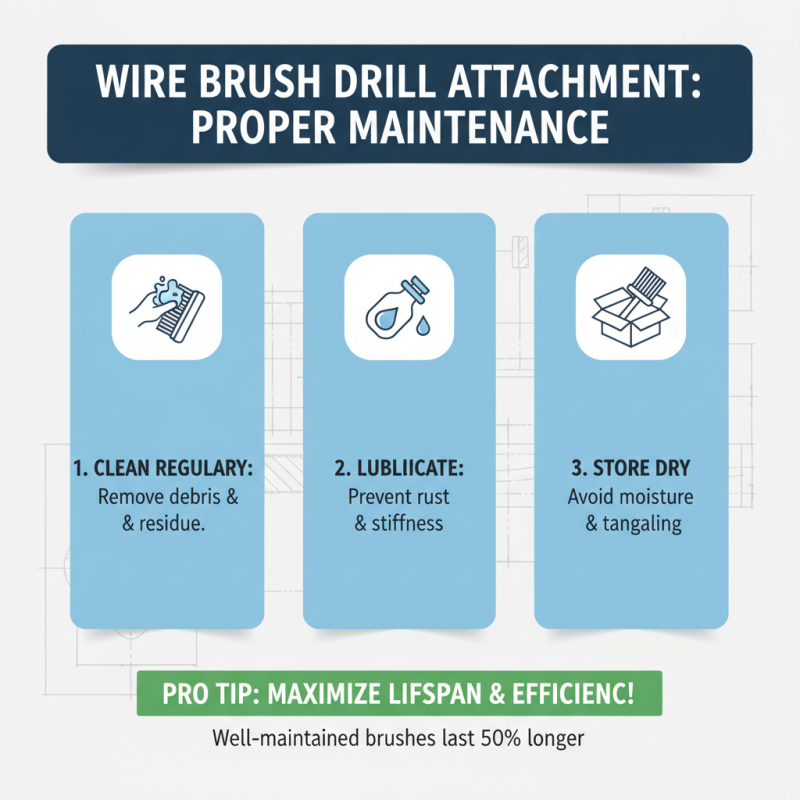

Maintenance Tips for Prolonging the Life of Wire Brush Attachments

When it comes to wire brush drill attachments, proper maintenance is essential for maximizing their lifespan and efficiency. According to industry data, the average lifespan of wire brushes can vary significantly based on usage, with poorly maintained brushes lasting up to 50% less than their well-maintained counterparts. To ensure you get the most out of your attachments, consider adopting some proactive care strategies.

One of the most effective tips is to regularly inspect your wire brush attachments for wear and tear. Look for signs of fraying or loss of bristles, which can decrease performance and lead to ineffective cleaning. Additionally, keeping the brushes clean and free from debris can prevent buildup that could compromise their function. Utilizing a clean brush or a mild detergent can help maintain the integrity of the bristles while enhancing their cleaning capabilities.

Another important aspect of maintenance is storing wire brush attachments properly. A study by the National Institute of Standards and Technology emphasized that improper storage can lead to rust and corrosion, significantly shortening the lifespan of your tools. Store your brushes in a dry, cool place and avoid exposing them to moisture or extreme temperatures. By following these maintenance tips, you can ensure that your wire brush drill attachments remain efficient and effective throughout their use.

Related Posts

-

10 Best Stainless Steel Mesh Options for Versatile Applications

-

What is a Stainless Steel Supplier and How to Choose the Right One

-

Why Stainless Steel Mesh Screens Are Essential for Your Home and Industry Needs

-

2025 How to Choose the Best Stainless Steel Mesh Screen for Your Needs

-

Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

-

Discovering the Versatility of 316 Stainless Steel: Applications You Never Knew About