The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects

In the construction industry, the significance of selecting the appropriate materials cannot be overstated, and one such crucial component is tie wire. According to a report by the American Concrete Institute, approximately 70% of construction professionals identify the performance of tie wire as a key factor in ensuring structural integrity. With the global tie wire market expected to reach USD 2.5 billion by 2026, understanding the various types, strengths, and applications of tie wire becomes essential for achieving project success. As construction demands evolve, opting for the best tie wire not only enhances safety and efficiency but also facilitates compliance with industry standards, making this guide indispensable for contractors and builders aiming for excellence in their projects.

Understanding the Different Types of Tie Wire Used in Construction Projects

When it comes to construction projects, choosing the right tie wire is crucial for ensuring structural integrity. There are several types of tie wire, each designed for specific applications.

One common type is galvanized tie wire, known for its corrosion resistance, making it ideal for outdoor projects or areas exposed to moisture. This type of wire is often used in concrete reinforcement and forming applications because it can withstand the elements while providing the necessary support.

One common type is galvanized tie wire, known for its corrosion resistance, making it ideal for outdoor projects or areas exposed to moisture. This type of wire is often used in concrete reinforcement and forming applications because it can withstand the elements while providing the necessary support.

Another important type is annealed tie wire, which is softer and more pliable than galvanized wire. This flexibility allows for easy handling and manipulation, making it perfect for tying rebar and other materials securely. Its ease of use can expedite the construction process, which is particularly valuable on large job sites.

Additionally, there are specialty tie wires, such as stainless steel options, designed for high-end construction projects where durability and aesthetics are paramount.

Understanding these various types of tie wire and their specific applications will help contractors select the best option for their construction needs.

Key Specifications to Consider When Selecting Tie Wire for Construction

When selecting tie wire for construction projects, several key specifications must be taken into account to ensure efficiency and safety. First, the material type is critical. Tie wires are commonly made from steel, stainless steel, and copper, each offering distinct properties. For instance, galvanized steel wires can provide enhanced corrosion resistance, with a reported lifespan increase of up to 50% in humid environments, according to industry studies.

Another vital specification is the wire gauge. The American Wire Gauge (AWG) standard indicates a wire’s thickness, which affects its tensile strength and durability. Typically, a gauge between 12 and 16 is preferred for most construction applications, balancing both strength and flexibility. Additionally, operating within the proper range ensures that the wire can support various loads without compromising structural integrity.

Tips: Always verify the wire's tensile strength before purchase, as specifications may vary between manufacturers. Also, consider environmental factors; choose materials that withstand local weather conditions. Remember to consult recent industry reports, such as those from the International Construction Organization, to stay updated on standards and innovations in tie wire technology.

Evaluating the Strength and Durability of Tie Wire Materials

When selecting tie wire for construction projects, evaluating the strength and durability of different wire materials is crucial. The most commonly used materials are galvanized steel and stainless steel. According to industry reports, galvanized steel offers a tensile strength between 60,000 to 80,000 PSI, making it a favored choice for reinforcement in concrete applications. Meanwhile, stainless steel, known for its superior corrosion resistance, maintains a similar tensile strength but excels in environments prone to humidity and moisture.

Tips for making an informed choice include considering the specific environmental conditions of your project. For wet or coastal areas, stainless steel is recommended due to its enhanced durability against corrosion. On the other hand, for dry climates where exposure to moisture is minimal, galvanized wire can be both a cost-effective and strong solution. Additionally, always check the ASTM standards for tie wire, such as ASTM A641 for galvanized wire, to ensure quality and compliance with industry regulations.

Investing time in evaluating these materials can save both money and time in the long run, preventing potential failures in structural integrity. When in doubt, consulting with suppliers who understand the local conditions and regulatory standards can further guide your decision-making process.

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects

| Material | Strength (MPa) | Durability (Years) | Weight (g/m) | Cost per Meter ($) |

|---|---|---|---|---|

| Galvanized Steel | 350 | 10 | 5 | 0.15 |

| Stainless Steel | 600 | 15 | 4 | 0.25 |

| Coated Wire | 300 | 7 | 6 | 0.12 |

| PVC Wire | 200 | 5 | 3 | 0.08 |

| Aluminum Wire | 250 | 8 | 5 | 0.10 |

Understanding Local Building Codes and Standards for Tie Wire Use

When embarking on construction projects, understanding local building codes and standards for tie wire use is crucial. These regulations vary by region and typically specify the types of materials that can be used, the gauge of the wire, and how it should be installed to ensure safety and structural integrity. Ignoring these codes can lead to costly fines or, worse, unsafe structures. Therefore, it is essential for contractors and builders to familiarize themselves with local regulations before choosing the right tie wire.

In addition to safety considerations, adhering to local standards can also streamline the construction process. Many jurisdictions require inspections at different project stages, and using approved materials—such as the appropriate tie wire—can facilitate these inspections and ensure compliance. Moreover, some building codes may dictate the use of tie wires in specific applications, such as reinforcing concrete or securing framing materials. Engaging with local building authorities or referencing official documentation can help builders navigate these requirements effectively and choose the best tie wire for their specific project needs.

Cost-Effectiveness: How to Choose the Right Tie Wire for Your Budget

When selecting tie wire for construction projects, understanding cost-effectiveness is essential for maintaining your budget while ensuring quality. Start by evaluating your project needs, including the types of materials you'll be working with and the environmental conditions that may affect wire durability. Tie wires come in various materials, such as galvanized steel, stainless steel, and even plastic, each with distinct price points. Ultimately, choosing a wire that balances durability and affordability is key to containing costs without compromising structural integrity.

Another critical factor in cost-effectiveness is considering the wire's diameter and tensile strength. Thicker wires might be more expensive but can offer greater strength and longevity, reducing the frequency of replacements needed over time. Additionally, purchasing in bulk or from suppliers that provide competitive pricing can further enhance your budgetary control. Analyzing these factors will enable you to select the right tie wire that meets both your budget constraints and project specifications, ensuring a successful and financially prudent construction effort.

Related Posts

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

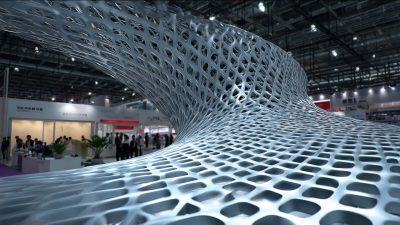

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025

-

Discovering the Versatility and Durability of 304 Stainless Steel in Modern Applications

-

Revitalize Your Cleaning Routine: Discover the Power of Steel Brushes for Every Task

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

Exploring the Benefits of Steel Mesh: The Ultimate Guide for Builders and DIY Enthusiasts