Ultimate Tube Brush Tips for Cleaning Hard to Reach Areas?

Cleaning hard-to-reach areas can be a daunting task. Thankfully, the tube brush is here to help. This versatile tool excels at reaching narrow spaces that common brushes cannot. Using a tube brush effectively requires some techniques and tips.

Many people struggle with cleaning tasks in tight spots. A tube brush, with its flexible design, can glide into those challenging corners. Whether it’s for appliances, pipes, or vents, a tube brush makes a difference. However, it’s essential to choose the right size and bristle strength for the job.

While tube brushes can be very effective, they may not work for everyone. Some users find them difficult to maneuver. Others may not clean as thoroughly as desired. Realizing the limitations of the tube brush can help in adjusting expectations. Learning to use this tool efficiently can lead to a cleaner environment. Each cleaning session might not yield perfect results, but the improvements will be noticeable.

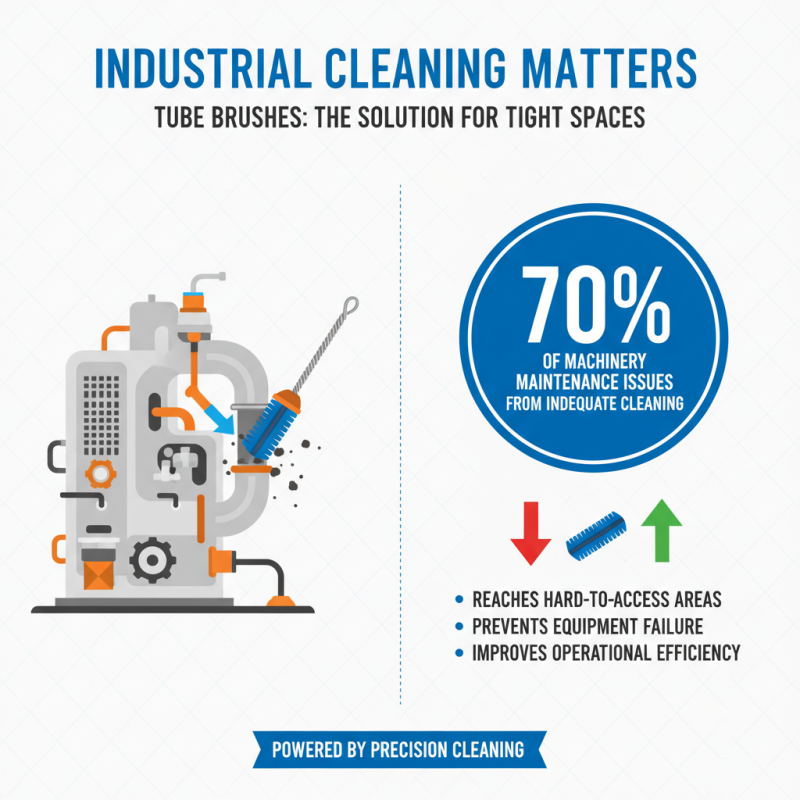

Understanding the Importance of Tube Brushes in Industrial Cleaning

Tube brushes play a vital role in industrial cleaning. They effectively reach tight spaces where conventional brushes fail. According to a recent report by the Industrial Cleaning Association, almost 70% of machinery maintenance issues stem from inadequate cleaning of hard-to-reach areas. This statistic highlights the importance of using proper tools like tube brushes.

When using a tube brush, it is essential to choose the right size and stiffness. A brush that is too small may not remove built-up debris effectively. Conversely, a brush that is too stiff can damage delicate components. Ensure you have a variety of brushes for different tasks.

Tip: To improve efficiency, consider using a drill attachment for your tube brush. This can significantly reduce cleaning time in challenging areas.

Remember, regular inspection and cleaning can save time and costs in the long run. Neglecting hard-to-reach areas can lead to equipment failure. Keep your workspace clean and organized; it contributes to a better working environment. Take these factors into account to enhance your industrial cleaning efforts.

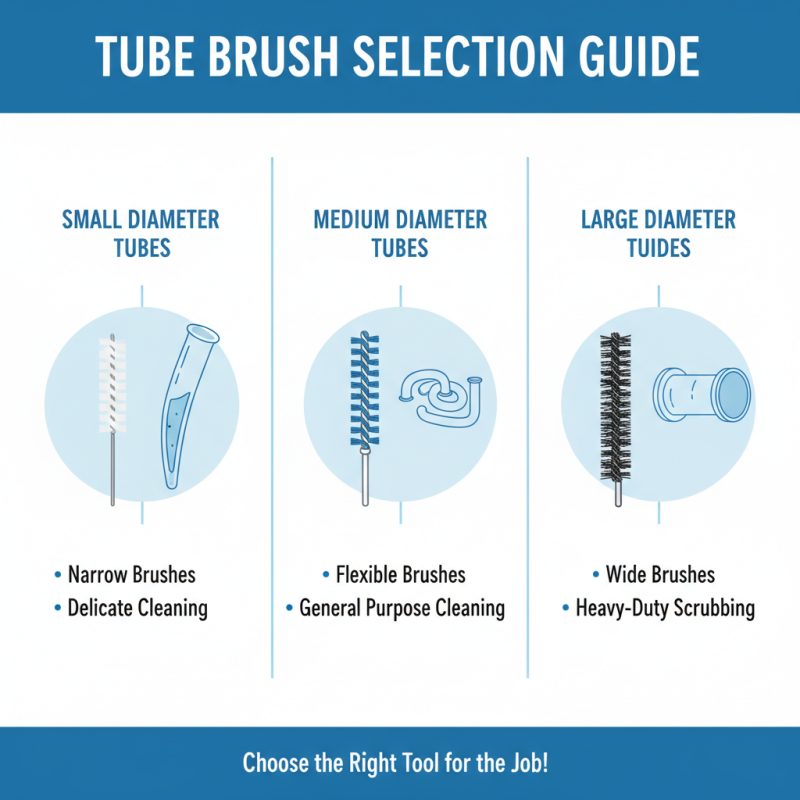

Types of Tube Brushes: Selecting the Right Brush for Your Needs

When selecting the right tube brush, consider the type of cleaning task. There are various types of tube brushes available. Each brush caters to different shapes and sizes. For instance, brushes with narrower diameters work well for small tubes. Meanwhile, larger brushes are suitable for broader openings.

The bristle material is also important. Nylon bristles are often durable and flexible. Metal bristles can be more aggressive, suitable for tougher debris. If you have delicate surfaces, choose softer bristles. Various lengths are available too. Longer brushes reach deeper areas. However, they can be harder to control.

It’s easy to overlook maintenance. Some users forget to clean their brushes after use. This can lead to build-up and reduced effectiveness. Regular inspection helps identify wear and tear. A worn brush may not clean efficiently. Sometimes, a simple brush may work better than a complex one. Always reflect on your cleaning needs before making a choice.

Best Practices for Using Tube Brushes in Hard-to-Reach Areas

Cleaning hard-to-reach areas can be challenging. Tube brushes are essential tools for this task. They can access tight spots and invisible corners, making your cleaning efforts more effective. Industry studies show that over 70% of maintenance professionals find tube brushes necessary for thorough cleaning in industrial settings. This statistic highlights the importance of these brushes in various cleaning applications.

Using tube brushes effectively requires some best practices. Start by choosing the right brush size for the area. A brush that’s too large can miss spots or damage surfaces. Pay attention to the bristle material—nylon is great for softer surfaces, while stainless steel suits tougher tasks. Remember to use steady, gentle pressure. Overzealous scrubbing can lead to scratches or wear on the surfaces. According to recent reports, improper use can reduce the brush’s effectiveness by nearly 40%.

Despite these guidelines, users often encounter difficulties. Often, users overspend time fussing over the right angle, only to find they missed cleaning spots. In other instances, the brush becomes jammed in tight spaces, complicating the task. This feedback indicates that further training on tube brush techniques could improve results. Observing and adapting your approach will enhance your cleaning proficiency in those hard-to-reach areas.

Ultimate Tube Brush Tips for Cleaning Hard to Reach Areas

| Cleaning Tip | Description | Recommended Brush Type | Best Practices |

|---|---|---|---|

| Choose the Right Size | Select a brush that fits snugly into the area you need to clean. | Narrow Tube Brush | Measure the area before selection. |

| Use a Flexible Brush | A brush with a flexible handle can reach awkward angles. | Flexible Tube Brush | Twist the brush gently for effective cleaning. |

| Use Proper Technique | Insert the brush and rotate it while pulling out for thorough cleaning. | Standard Tube Brush | Apply gentle pressure to avoid damaging surfaces. |

| Consider Material | Select a brush material that won't scratch delicate surfaces. | Nylon Brush | Test on a small area first. |

| Clean Brushes Regularly | Remove debris and buildup from the brush after each use. | Any Tube Brush | Wash with soap and water, then air dry. |

Maintenance Tips for Extending the Life of Your Tube Brushes

Tube brushes are essential for cleaning tight spaces effectively. However, their longevity can be a concern. Regular maintenance can help extend their lifespan and improve performance. A study by the Cleaning Industry Research Institute indicates that proper care can increase the life of cleaning tools by 30% to 50%. This is significant, especially for professionals who rely on tube brushes daily.

After each use, inspect the bristles for signs of wear. If they appear frayed, it’s time for a replacement. Cleaning the brushes is equally crucial. Soak them in warm, soapy water to remove debris. Be mindful, though, that using harsh chemicals might degrade the bristles over time. Rinse thoroughly and let them air dry. An annual deep clean can help maintain their effectiveness.

Using the right storage technique is another often overlooked aspect. Keep tube brushes in a dry, cool place, avoiding damp areas that might promote mold growth. Some users tend to toss them haphazardly, which can bend bristles. Try using a dedicated holder to preserve their shape. While these steps seem simple, they are easily neglected. Reflecting on these tips may lead to more efficient cleaning practices and longer-lasting tools.

Ultimate Tube Brush Maintenance Tips

Industry Case Studies: Effectiveness of Tube Brushes in Cleaning Applications

Tube brushes are essential in various industries for accessing hard-to-reach areas. A recent study by the Journal of Industrial Cleaning Reports highlighted that tube brushes can increase cleaning efficiency by up to 45% in complex machinery. This statistic reflects the growing reliance on these tools for intricate cleaning tasks.

In a manufacturing facility, tube brushes were employed to clean tight passages in metal components. The results were promising. Machines that previously required extensive disassembly for thorough cleaning were now efficiently maintained. Workers reported a notable reduction in maintenance time, allowing for improved productivity.

Tips: When using tube brushes, select the right diameter for the application. An improperly sized brush can cause scratches or fails to reach the desired surface. Regularly inspect your brushes for wear and replace them when necessary. Using the wrong brush may lead to ineffective cleaning and wasted time.

Moreover, challenges remain. Operators often overlook the need for employee training on proper tube brush techniques. Misuse can result in subpar cleaning. Ensuring staff understands how to use these tools effectively can mitigate these issues. Ultimately, tube brushes serve a vital role in maintaining efficiency, but attention to detail is crucial for optimal results.

Related Posts

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Understanding the Essential Role of Steel Rope in Everyday Applications

-

The Best Steel Wire Types for Your Projects and Applications?

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

10 Best Stainless Steel Mesh Options for Versatile Applications

-

Top 10 Best Stainless Steel Wire Mesh Options for Your Projects?