Top 10 Uses of Stainless Steel Wire in Everyday Applications

Stainless steel wire plays a vital role in many industries. This material is known for its strength, flexibility, and resistance to corrosion. According to a recent report by Grand View Research, the global stainless steel market is projected to reach $200 billion by 2028. A major contributor to this growth is the rising demand for stainless steel wire across various applications.

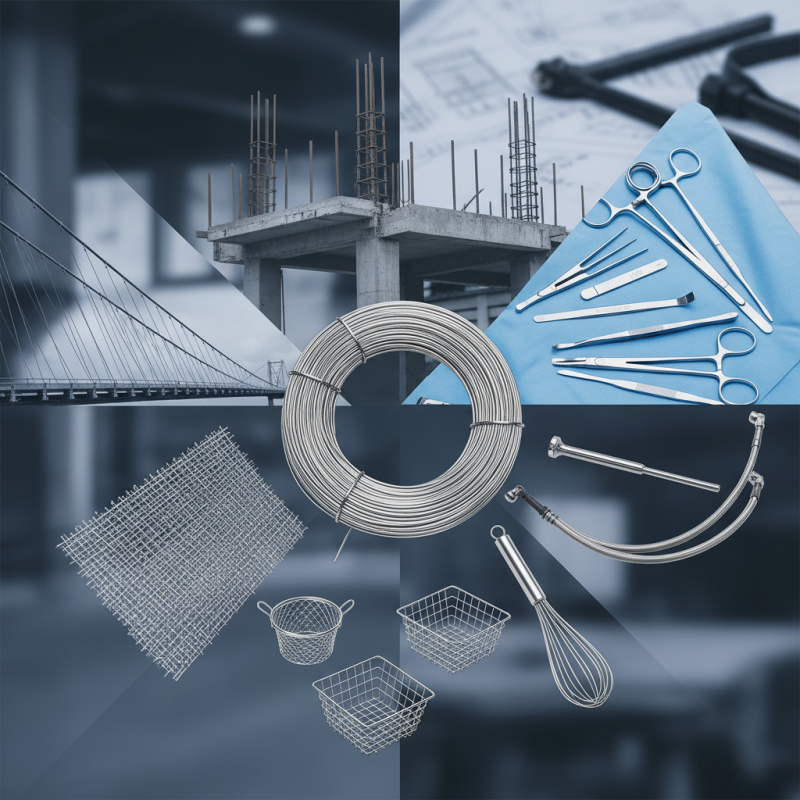

In everyday life, stainless steel wire is used in construction, automotive, and healthcare industries. Its applications range from safety cables to surgical instruments, showcasing its versatility. Notably, the building sector utilizes stainless steel wire for reinforcement. This enhances the longevity and durability of structures. Additionally, in the automotive industry, it is integral in producing parts that need to withstand harsh conditions. These examples highlight how stainless steel wire is essential to modern life.

As we explore the top uses of stainless steel wire, it's clear that its value is substantial. However, there are challenges as well. Not all applications maximize its potential. Some industries may overlook the benefits of using stainless steel wire. Addressing these gaps can improve efficiency and safety in various fields.

Applications of Stainless Steel Wire in Construction and Architecture

Stainless steel wire plays a significant role in construction and architecture. It is strong and durable, making it ideal for various applications. In foundations, stainless steel wire is often used to reinforce concrete. This helps to distribute loads evenly, increasing structural integrity. It resists corrosion, ensuring longevity in different environments.

Another interesting application is in architectural design. Stainless steel wire can support facades and decorative features. It provides an elegant look without sacrificing strength. For instance, suspension bridges utilize stainless steel wire for their cables. It allows for long spans and creates striking visual lines. However, the installation process can be complex and requires skilled labor.

Despite its advantages, challenges exist. Proper handling is crucial to prevent rust during the construction phase. Environmental factors can also impact its performance over time. Regular maintenance is necessary to preserve its appearance and functionality. The versatility of stainless steel wire is impressive, but awareness of these issues is essential for successful application.

Role of Stainless Steel Wire in Home Appliances and Kitchenware

Stainless steel wire plays a vital role in home appliances and kitchenware. It is known for its strength and durability. Many kitchen utensils are made from this versatile material. For instance, stainless steel wire is commonly found in whisks and strainers. These tools are lightweight yet effective. They handle daily wear and tear well, maintaining functionality over time.

In appliances, stainless steel wire is often used in heating elements. It ensures even cooking and durability. Many toasters and ovens use this wire for its excellent thermal conductivity. However, it’s not without issues. Over time, the wire may corrode if not maintained properly. Users must be vigilant about cleaning.

Stainless steel wire also supports safety features in kitchen tools. As a component of shelving, it helps organize space efficiently. While strong, it can bend under excessive weight. Kitchenware made from this material often requires careful handling. So, while stainless steel wire is useful, it demands regular inspection and maintenance to ensure optimal performance.

Uses of Stainless Steel Wire in Electrical and Electronic Devices

Stainless steel wire plays a crucial role in various electrical and electronic devices. One common use is in connectors. These wires ensure a reliable link between components. They withstand corrosion and heat, making them ideal for harsh environments. Imagine a device exposed to moisture and heat. Stainless steel wire keeps it functional over time.

In electronic circuits, stainless steel wire is often used for shielding. This prevents interference from external signals. Such interference can disrupt performance. The wire wraps around sensitive components, creating a protective layer. However, if not properly implemented, it may not provide the intended protection.

Another application is in the formation of springs and contacts. The elasticity of stainless steel wire allows for effective mechanical functions. Unfortunately, improper tensioning can lead to failure. Insufficient quality control during manufacturing may result in flawed components. Each application requires careful design and testing. It is this attention to detail that enhances the reliability of electronic devices.

Top 10 Uses of Stainless Steel Wire in Everyday Applications

| Application | Description | Wire Gauge | Benefits | |

|---|---|---|---|---|

| Electrical Wiring | Used for making electrical connections due to its conductivity and resistance to corrosion. | 16 - 18 AWG | Durability, corrosion resistance | |

| Electronic Components | Utilized in manufacturing electronic components like resistors and capacitors. | 24 - 30 AWG | Thermal stability, longevity | |

| Telecommunication | Wire used in the construction of telecommunication cables. | 18 - 20 AWG | Signal integrity, weather resistance | |

| Data Cables | Incorporated in data transmission cables to enhance performance. | 22 - 26 AWG | High-speed data transfer | |

| Heating Elements | Used in manufacturing heating elements for appliances. | 16 - 20 AWG | High thermal resistance | |

| Lifting and Rigging | Applied in lifting devices and rigging due to its strength. | 10 - 14 AWG | Strength, safety | |

| Fencing | Commonly used in fence construction for durability. | 14 - 16 AWG | Weather resistance, aesthetics | |

| Spring Production | Can be used to create springs for various applications. | 0.2 - 0.5 mm | Flexibility, resilience | |

| Jewelry Making | Utilized in crafting jewelry items due to its aesthetic appeal. | 20 - 24 AWG | Corrosion resistance, beauty |

Stainless Steel Wire Applications in Automotive and Transportation Industries

Stainless steel wire is increasingly vital in the automotive and transportation industries. This material provides strength, durability, and resistance to corrosion, making it ideal for various applications. According to recent industry reports, over 50% of automotive components now utilize stainless steel wire in some form, enhancing vehicle longevity and safety.

For instance, stainless steel wires are essential in the manufacturing of brake cables and suspension systems. These components must withstand extreme conditions. The tensile strength of stainless steel wire often reaches as high as 200,000 psi. This allows for reliable performance even under significant stress. Yet, the dependency on this wire poses challenges. Manufacturing inconsistencies can sometimes lead to failure, highlighting a need for improved quality control measures in production lines.

In addition, the use of stainless steel wire in electrical systems is critical. It provides excellent conductivity while resisting rust and environmental factors. Notably, nearly 30% of electrical failures in vehicles are due to subpar materials. This emphasizes the importance of investing in high-quality stainless steel wire. Transportation relies heavily on these materials, but the industry must address these gaps. Proper material selection is crucial for enhancing reliability and safety.

Innovative Uses of Stainless Steel Wire in Art and Decorative Crafts

Stainless steel wire has found innovative applications in art and decorative crafts. Artists appreciate its durability and versatility. Its resistance to rust and corrosion makes it ideal for outdoor installations. According to industry reports, the global market for metal art is growing at a rate of 6.5% annually. This indicates a rising interest in using materials like stainless steel wire in creative expressions.

In decorative crafts, stainless steel wire is often used for sculpting. Artists coil, twist, and shape it into intricate designs. Its malleability allows for unique creations that withstand the test of time. A study found that around 35% of artists prefer stainless steel for its structural integrity. It can hold its shape well, making it preferable for sculpture and jewelry making.

Yet, using stainless steel wire has its challenges. It can be difficult to work with due to its hardness. Tools often need to be heavy-duty to manage it effectively. Some artists report struggles with achieving precise bends. However, these hurdles can lead to personal growth and improved techniques over time. The artistic journey with stainless steel wire can be rewarding despite these imperfections.

Related Posts

-

Exploring the Versatility of Stainless Steel Wire: Applications in Everyday Life and Industry

-

Top 10 Stainless Steel Supplier Factors Influencing Market Growth and Demand in 2023

-

Best Small Wire Brush Options for Cleaning and Maintenance in 2025

-

10 Essential Tips for Using a Wire Brush Effectively in Your Projects

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

2025 How to Choose the Best MIG Wire for Optimal Welding Performance