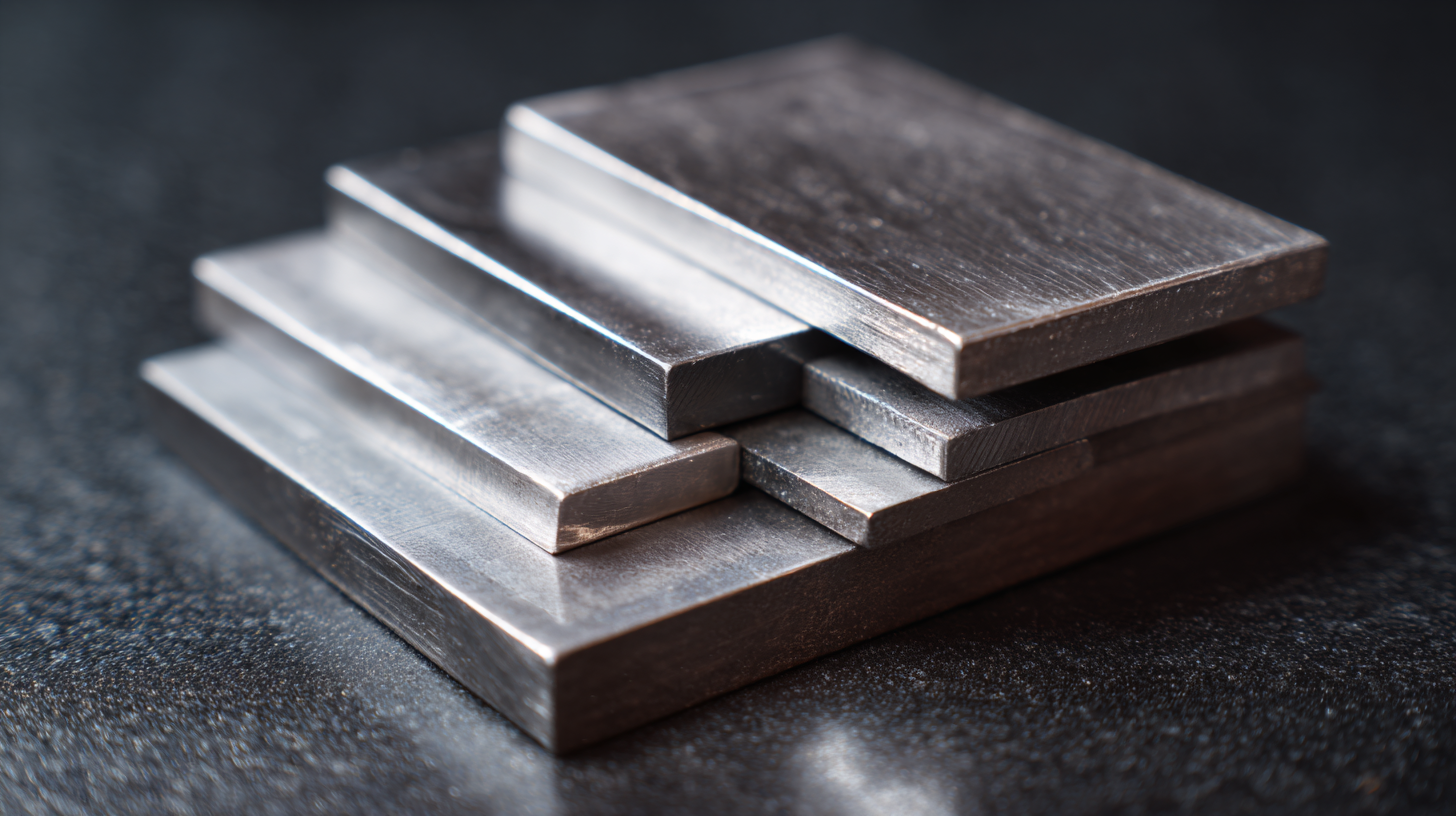

Discovering the Versatility of 316 Stainless Steel: Applications You Never Knew About

316 stainless steel is widely recognized for its exceptional corrosion resistance and strength, making it a preferred material in various industries. According to the latest market research, the demand for stainless steel, particularly types 304 and 316, is projected to reach approximately 50 million metric tons by 2025, driven by their versatile applications in sectors such as construction, automotive, and marine. Surprisingly, the applications of 316 stainless steel extend beyond the obvious uses in kitchenware and industrial equipment. It plays a critical role in innovative applications such as medical implants, marine environments, and chemical processing, where durability and reliability are paramount. This article delves into the lesser-known applications of 316 stainless steel, unveiling its remarkable versatility and highlighting why it continues to be indispensable across multiple fields.

The Unique Corrosion Resistance of 316 Stainless Steel in Marine Applications

The marine industry heavily relies on materials that can withstand harsh environmental conditions, and 316 stainless steel stands out for its exceptional corrosion resistance. According to a report by the International Stainless Steel Forum (ISSF), 316 stainless steel is specifically formulated with molybdenum, which enhances its resistance to pitting in chloride environments, common in seawater. This unique property makes it an ideal choice for manufacturing various marine components, including boat fittings, pumps, and piping systems.

One notable advantage of 316 stainless steel in marine applications is its longevity. A study published in the Journal of Materials Engineering and Performance noted that structures made from 316 stainless steel exhibited a service life of 50 years or more in marine conditions, significantly reducing the need for frequent replacements and maintenance. With its ability to withstand the corrosive effects of saltwater and high humidity, industries are increasingly adopting 316 stainless steel for their offshore structures and marine vessels, ensuring both safety and durability while optimizing long-term costs.

Discovering the Versatility of 316 Stainless Steel: Applications You Never Knew About - The Unique Corrosion Resistance of 316 Stainless Steel in Marine Applications

| Application | Description | Corrosion Resistance | Typical Environments |

|---|---|---|---|

| Marine Components | Used in shipbuilding, offshore oil rigs, and marine hardware. | Excellent resistance to seawater and corrosive environments. | Open sea, coastal construction, and ship applications. |

| Chemical Processing | Ideal for tanks, pipes, and valves in chemical plants. | Resistant to a wide variety of chemicals. | Chemical storage and processing plants. |

| Pharmaceutical Equipment | Used for fittings, pumps, and tanks in drug manufacturing. | Non-reactive and easy to clean; prevents contamination. | Pharmaceutical and biotechnology industries. |

| Food Processing | Utilized in equipment for food storage, processing, and transport. | Resistant to corrosion from acidic and alkaline foods. | Dairy, meat, and beverage industries. |

| Architectural Features | Used in facades, railings, and outdoor furniture. | Holds up well against weathering and environmental factors. | Coastal and urban environments. |

Innovative Uses of 316 Stainless Steel in Pharmaceutical and Food Processing Industries

316 stainless steel is renowned for its exceptional corrosion resistance and versatility, making it a preferred choice in various industries, particularly in pharmaceuticals and food processing. In the pharmaceutical sector, 316 stainless steel is used in the construction of equipment that must maintain stringent hygiene standards. Its ability to withstand sterilization processes and resist chemical reactions ensures that the integrity of pharmaceuticals is preserved, preventing contamination and ensuring product safety.

In the food processing industry, 316 stainless steel plays a critical role in the design of machinery and storage units. Its non-reactive surface is essential for food safety, as it prevents leaching of harmful substances into consumables. Furthermore, the durability and resistance to rust and staining enhance the longevity of food processing equipment, leading to increased operational efficiency and reduced maintenance costs. As the global stainless steel market continues to grow, forecasted to reach $1674.8 billion by 2030, the innovative applications of 316 stainless steel in these industries will undoubtedly expand, paving the way for continued advancements in health and safety standards.

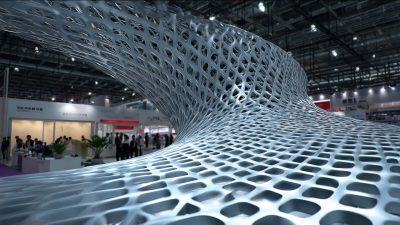

316 Stainless Steel: A Game Changer in Architectural and Structural Design

316 stainless steel is revolutionizing architectural and structural design due to its remarkable combination of strength, corrosion resistance, and aesthetic appeal. According to data from the International Stainless Steel Forum, the use of austenitic stainless steel grades, particularly 316, has seen an annual growth rate of about 5% in construction applications over the past decade. This is primarily attributed to its ability to withstand harsh environments, making it an ideal choice for buildings in coastal areas or regions exposed to corrosive elements.

In architectural applications, 316 stainless steel is not just a functional material; it also enhances the visual impact of structures. Its smooth finish and resistance to tarnishing ensure longevity and reduced maintenance costs, which are critical factors outlined in reports from the American Institute of Steel Construction. Moreover, the material's durability allows architects to explore innovative designs that incorporate organic shapes and large openings, fundamentally changing the approach to modern architectural aesthetics. As construction projects increasingly prioritize sustainability alongside design, 316 stainless steel emerges as a game-changing material that addresses both durability and environmental concerns.

Sustainable Solutions: 316 Stainless Steel's Role in Renewable Energy Systems

The role of 316 stainless steel in renewable energy systems is increasingly significant in today’s quest for sustainable solutions. This material’s excellent corrosion resistance and high-temperature strength make it an ideal candidate for applications in the renewable energy sector. For instance, its utilization in bioreactor systems for cultivating methane-producing microorganisms highlights how 316 stainless steel can support sustainable energy initiatives, particularly through biomethanation processes. This transformation is key to harnessing renewable energy from organic waste, ensuring that energy production aligns with environmental sustainability.

Tips: When considering materials for renewable energy applications, it’s essential to assess not only durability but also the environmental impact. Opting for materials like 316 stainless steel can help enhance the longevity of energy systems while reducing maintenance costs. Additionally, staying informed about advancements in technologies, such as 3D printing, can lead to innovative design solutions that further leverage the benefits of stainless steel in energy systems.

By integrating 316 stainless steel into designs for renewable energy technologies, industries can drive innovation and efficiency. The projected growth of the stainless steel seamless pipes market reflects this trend, underscoring the material’s vital role in supporting the global transition to sustainable energy infrastructures. As various sectors explore new energy solutions, the importance of versatile materials like 316 stainless steel will continue to be paramount.

Cost-Effectiveness of 316 Stainless Steel in Industrial Manufacturing Processes

The cost-effectiveness of 316 stainless steel in industrial manufacturing processes is increasingly recognized as a critical factor driving its widespread adoption. With the Stainless Steel Seamless Pipes Market projected to reach USD 5.15 billion by 2030, this versatile material is becoming a staple in various applications, ranging from chemical processing to marine environments. Its excellent corrosion resistance and high strength-to-weight ratio ensure that businesses can achieve longevity in their products while reducing maintenance costs.

Moreover, advancements in manufacturing techniques, such as laser metal deposition, have made it possible to enhance and repair components made from 316 stainless steel at lower costs. This method not only improves the durability of existing structures but also streamlines production processes, contributing to a more sustainable approach in industrial manufacturing. As a result, companies can leverage these innovations to optimize their operations and remain competitive in an ever-evolving market landscape.

Cost-Effectiveness of 316 Stainless Steel in Industrial Manufacturing Processes

Related Posts

-

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Innovative Trends and Market Insights for Welded Wire Mesh at the 2025 China Import and Export Fair

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects

-

Revitalize Your Cleaning Routine: Discover the Power of Steel Brushes for Every Task