The Versatility of Stainless Steel Cable: Applications, Benefits, and Innovations

Stainless steel cable has become an integral component across various industries due to its remarkable strength,

corrosion resistance, and flexibility. According to a report by the Stainless Steel Association, the demand for stainless steel cable is projected to grow at a CAGR of 4.5% over the next five years, driven largely by its applications in construction, marine, and automotive sectors. Its durability in harsh environments and aesthetic appeal also contribute to its growing popularity, with manufacturers focusing on eco-friendly production methods and innovative designs. As industries continue to evolve, the versatility of stainless steel cable not only meets the stringent requirements of contemporary engineering but also offers sustainable solutions for the future, making it a critical element in modern infrastructure and design.

Stainless steel cable has become an integral component across various industries due to its remarkable strength,

corrosion resistance, and flexibility. According to a report by the Stainless Steel Association, the demand for stainless steel cable is projected to grow at a CAGR of 4.5% over the next five years, driven largely by its applications in construction, marine, and automotive sectors. Its durability in harsh environments and aesthetic appeal also contribute to its growing popularity, with manufacturers focusing on eco-friendly production methods and innovative designs. As industries continue to evolve, the versatility of stainless steel cable not only meets the stringent requirements of contemporary engineering but also offers sustainable solutions for the future, making it a critical element in modern infrastructure and design.

Understanding the Composition and Properties of Stainless Steel Cable

Stainless steel cable is renowned for its exceptional strength, durability, and versatility, making it a preferred choice across various industries. Composed primarily of iron, chromium, and nickel, stainless steel offers superior corrosion resistance compared to traditional steels. According to a report by the Steel Construction Institute, stainless steel can withstand harsh environmental conditions, which is crucial for applications in marine, construction, and agricultural sectors. The chromium content, typically between 10% to 30%, forms a protective oxide layer that prevents rust and degradation, significantly extending the cable's lifespan.

Additionally, the mechanical properties of stainless steel cables vary depending on their specific alloy composition. For instance, the common AISI 316 stainless steel, which includes molybdenum, enhances resistance to pitting and crevice corrosion in chloride environments, making it ideal for coastal and offshore applications. A market analysis by Grand View Research indicates that the global stainless steel wire and cable market is projected to grow at a CAGR of over 5% from 2020 to 2027, driven by increasing demand in sectors such as automotive and construction, highlighting the expanding role of stainless steel cable innovations. This demand underscores the material's unique combination of properties, including its tensile strength, flexibility, and lightweight nature, which further enhance its suitability for various applications.

Identifying Key Applications of Stainless Steel Cable in Various Industries

Stainless steel cable has emerged as a versatile solution across various industries due to its durability, corrosion resistance, and strength. In construction, it is widely used for lifting and support systems, particularly in high-rise buildings and bridges, where safety and reliability are paramount. The automotive sector employs stainless steel cables for safety harnesses and other applications, benefiting from their ability to withstand extreme conditions. Moreover, in the marine industry, these cables are essential for rigging and mooring due to their ability to resist saltwater corrosion.

In addition to traditional applications, innovations in stainless steel cable technology have expanded its use in different sectors. For instance, the introduction of plastic coatings, such as PVC and PE, enhances the cable's durability and offers an additional layer of protection. This is particularly beneficial in environments where cables are exposed to harsh elements or require additional insulation. With ongoing advancements, stainless steel cables are also being explored for application in aerospace and defense, where performance under stress and reliability are critical for mission success.

The Versatility of Stainless Steel Cable: Applications, Benefits, and Innovations - Identifying Key Applications of Stainless Steel Cable in Various Industries

| Industry | Key Applications | Benefits | Innovations |

|---|---|---|---|

| Construction | Cable railing systems, tensioning systems | Durability, aesthetic appeal | Corrosion-resistant coatings |

| Maritime | Mooring lines, rigging | High strength-to-weight ratio, resistance to saltwater | Advanced weaving techniques |

| Aerospace | Control cables, safety harnesses | Lightweight, strong, reliable | Smart cable monitoring systems |

| Telecommunications | Supporting structures for cables, wire ropes | Weather-resistant, long lifespan | Integrated signal processing capabilities |

| Manufacturing | Conveyor systems, lifting equipment | Versatility, easy maintenance | Robotic integration for precision tasks |

Exploring the Benefits of Using Stainless Steel Cable Over Other Materials

Stainless steel cable has garnered significant attention in various industries due to its superior properties compared to other materials. One of the primary benefits of stainless steel cable is its remarkable resistance to corrosion. According to a report by the International Stainless Steel Forum, stainless steel offers a corrosion resistance level that can be ten times greater than that of traditional steel, making it ideal for harsh environments such as marine applications and chemical processing. This durability not only extends the lifespan of the cable but also reduces maintenance costs significantly; some studies suggest a reduction in maintenance expenses by up to 40% when using stainless steel cable in place of conventional materials.

In addition to corrosion resistance, stainless steel cables exhibit exceptional tensile strength, allowing them to handle heavy loads and withstand extreme conditions. A research analysis published by the American Society of Mechanical Engineers highlights that stainless steel cables can provide a tensile strength ranging from 170,000 psi to 250,000 psi, depending on the alloy used. This strength, combined with lightweight properties, makes stainless steel cable a preferred choice in industries such as construction, aerospace, and transportation. As innovations continue to emerge, the versatility of stainless steel cables is set to expand further, driving both efficiency and safety in their applications.

Innovations in Stainless Steel Cable Technology: Trends and Developments

Recent advancements in stainless steel cable technology have positioned it as a preferred choice across various industries, from construction to telecommunications. According to a report by MarketsandMarkets, the global stainless steel wire market is expected to grow from USD 2.1 billion in 2021 to USD 2.6 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.5%. This growth is attributed to the material's excellent corrosion resistance and tensile strength, making it ideal for demanding environments.

Innovations such as the introduction of braided and multi-strand cables are enhancing performance and flexibility. For instance, new manufacturing techniques allow for the production of customized stainless steel cables that can withstand harsher conditions while maintaining lightweight properties. This is particularly beneficial in sectors such as marine and aerospace, where lightweight yet strong materials are critical.

Innovations such as the introduction of braided and multi-strand cables are enhancing performance and flexibility. For instance, new manufacturing techniques allow for the production of customized stainless steel cables that can withstand harsher conditions while maintaining lightweight properties. This is particularly beneficial in sectors such as marine and aerospace, where lightweight yet strong materials are critical.

Tips: When selecting stainless steel cables, consider the specific environmental conditions they will face. For coastal applications, cables with enhanced corrosion resistance are essential. Additionally, ensure that the diameter and construction of the cable align with the load requirements to optimize safety and longevity. Regular inspections can also help in detecting wear and prolonging the lifespan of the cables.

Maintenance Tips for Maximizing the Lifespan of Stainless Steel Cable Systems

Stainless steel cable systems are widely appreciated for their versatility in various industries, balancing aesthetics and functionality. However, like any equipment, ensuring their longevity requires diligent maintenance practices. Implementing total preventative maintenance (TPM) can be particularly transformative, not just for conveyor systems in sectors like pet food processing but for stainless steel cable applications as well. According to industry research, regular maintenance can reduce equipment failure rates by up to 30%, significantly extending the lifespan of components.

One crucial aspect of maintaining stainless steel cables involves routine inspections for signs of wear, corrosion, or fraying. The American Institute of Steel Construction highlights that proper maintenance can enhance tensile strength and resistance to environmental factors. Additionally, lubricating moving parts and ensuring proper installation can prevent undue stress on cables, which can lead to premature failure. Implementing a proactive maintenance schedule based on these insights can ensure stainless steel cable systems operate at their optimal performance for years, thereby safeguarding investment and enhancing operational efficiency across numerous applications.

Related Posts

-

The Ultimate Guide to Choosing the Right Stainless Steel Supplier for Your Projects

-

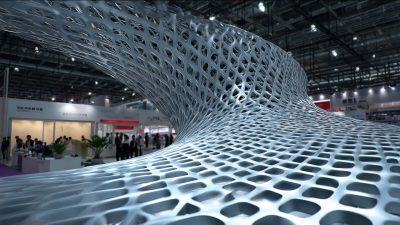

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

Exploring the Benefits of Steel Mesh: The Ultimate Guide for Builders and DIY Enthusiasts

-

Revitalize Your Cleaning Routine: Discover the Power of Steel Brushes for Every Task