Why is Welded Wire Mesh Essential for Construction and Agriculture?

Welded wire mesh plays a crucial role in both construction and agriculture. It offers strength, durability, and versatility. According to expert John Smith, a leading figure in the welded wire mesh industry, “This material is the backbone of modern infrastructure and farming.” His statement highlights the importance of welded wire mesh in enhancing safety and efficiency in projects.

In construction, welded wire mesh provides reliable reinforcement. It is used in concrete slabs and walls, ensuring stability. In agriculture, it serves as fencing, supporting crops while deterring pests. However, there is a gap in knowledge about its full potential. Many people overlook the various applications and benefits of welded wire mesh.

While its benefits are clear, challenges remain. Manufacturers sometimes struggle with quality control. Not all welded wire meshes are created equal. Each project demands specific requirements, which can lead to confusion. A better understanding of welded wire mesh is essential for its optimal use in both sectors.

Importance of Welded Wire Mesh in Construction Projects

Welded wire mesh plays a vital role in construction projects. It provides reinforcement for concrete slabs, walls, and floors. Reports indicate that using welded wire mesh can increase a structure's strength by up to 30%. This enhancement helps prevent cracking and shifting over time.

In addition to structural support, welded wire mesh improves safety on job sites. It helps secure temporary structures and fences. OSHA reports show that proper safety measures reduce accidents by about 40% in construction zones. However, many companies still overlook mesh installation, leading to increased risks and potential liability issues.

Moreover, the cost-effectiveness of welded wire mesh is noteworthy. It can reduce material waste and lower labor costs. Yet, some builders may hesitate due to initial investment concerns. Choosing quality materials is crucial. Neglecting this can lead to future expenses that outweigh initial savings. The balance between upfront costs and long-term benefits is often challenging to gauge.

Importance of Welded Wire Mesh in Construction Projects

Benefits of Welded Wire Mesh in Agricultural Applications

Welded wire mesh plays a vital role in agriculture. Its versatility makes it ideal for various applications, from crop protection to livestock containment. According to a recent industry report, nearly 70% of farmers in North America use welded wire mesh for fencing and trellising. This statistic highlights its importance in enhancing productivity.

Farmers appreciate its durability and strength. The mesh prevents animals from intruding into fields, protecting crops from grazing. In a study by the Agricultural Research Service, crops enclosed with welded wire fences showed a 25% increase in yield compared to those without barriers. This is significant for farmers aiming to maximize output.

However, challenges exist. Many farmers report issues with rust and corrosion over time, especially in humid areas. Regular maintenance is crucial. Additionally, some mesh styles may not suit all types of crops. It’s essential to evaluate specific needs before making a choice. The right welded wire mesh can transform agricultural practices, but careful consideration is necessary for optimal results.

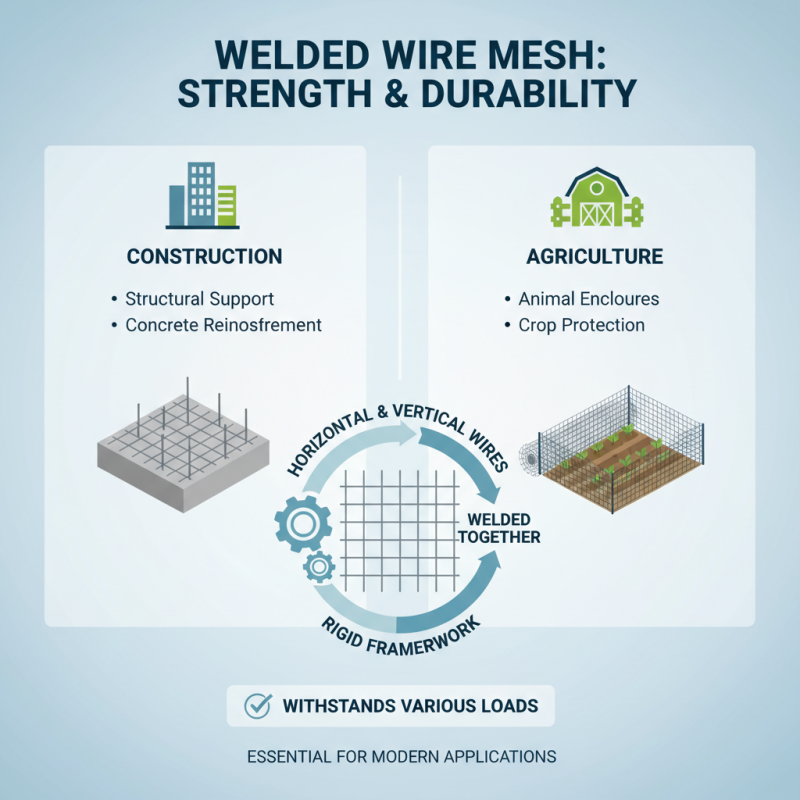

Key Features of Welded Wire Mesh for Structural Integrity

Welded wire mesh plays a crucial role in both construction and agriculture. Its structural integrity is essential for ensuring durability and strength. This mesh is crafted by welding horizontal and vertical wires together, creating a rigid framework. The result? A sturdy support system that can withstand various loads.

In construction, welded wire mesh is used in slabs, walls, and foundations. It provides reinforcement, helping to prevent cracking and shifting. In agriculture, it serves as fencing material or plant support, ensuring crops can thrive without interference. However, not all welded wire meshes are created equal. Some may lack durability or corrosion resistance, impacting their effectiveness over time.

When implementing welded wire mesh, consider the environmental factors it will face. The choice of materials and wire thickness can significantly influence performance. Regular inspections are vital to identify potential weaknesses. Ultimately, while welded wire mesh offers many benefits, careful selection and maintenance are key to maximizing its potential.

Applications of Welded Wire Mesh in Different Industries

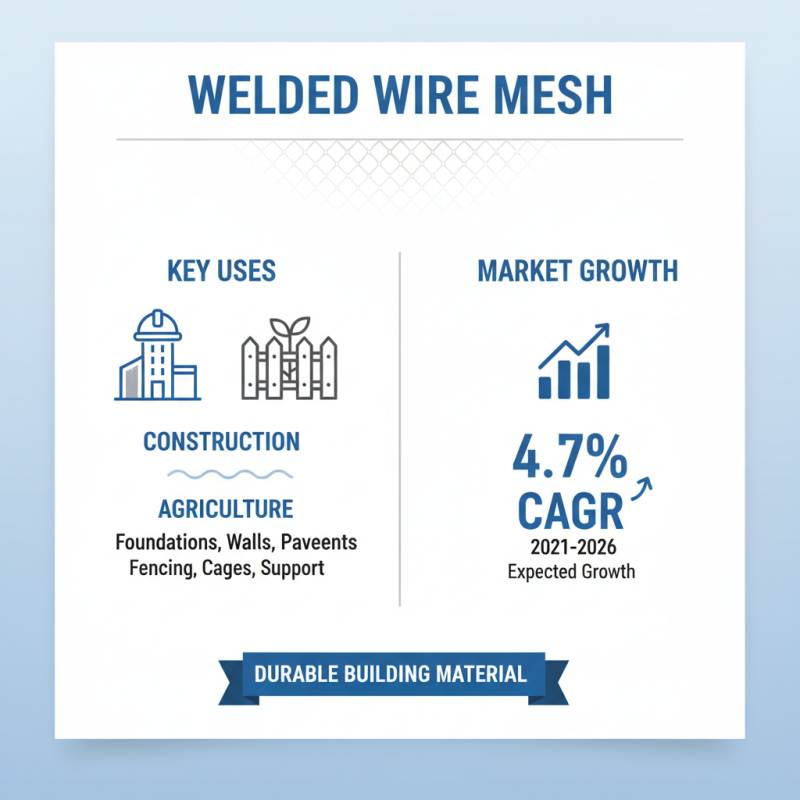

Welded wire mesh is widely used in construction and agriculture. This material plays a crucial role in reinforcing structures. It provides strength without adding much weight. In the construction industry, it is often used in foundations, walls, and pavements. According to a report by Research and Markets, the global market for welded wire mesh is expected to grow at a CAGR of 4.7% from 2021 to 2026. This growth reflects the increasing demand for durable building materials.

In agriculture, welded wire mesh has various applications. It is used in fencing, cages, and supports for plants. Farmers rely on it to protect crops from pests and animals. The mesh's durability ensures longevity in harsh environments. The agricultural segment accounts for approximately 30% of the welded wire mesh market, as reported by IBISWorld. However, the reliance on this material raises questions about sustainability and environmental impact.

Some industries may overlook the potential downsides of welded wire mesh. For instance, production processes can consume significant energy and resources. This fact calls for a careful examination of its lifecycle. There is an ongoing need to innovate and seek alternative materials that are both functional and environmentally friendly. Addressing these concerns will be vital as industries continue to grow.

Selection Criteria for Quality Welded Wire Mesh Products

When selecting welded wire mesh, quality is crucial. Look for a product that is durable and versatile. The wire gauge determines strength. Thicker wires typically offer more support. Consider the mesh opening size too, as it affects application. A smaller opening can secure smaller animals, while larger openings are better for drainage.

Check the welding quality. Uneven welds can weaken the structure. Poor welds may lead to breakage over time. Inspect for rust and corrosion as well. These can compromise integrity. Depending on the environment, galvanized or coated options might be necessary.

Always consider the intended use. For agricultural applications, a rust-resistant material is essential. In construction, strength and stability are priorities. Think about how it will be exposed to weather elements. Sometimes, the right mesh can make or break a project. Balancing cost and quality is not always easy. Getting it wrong can lead to more expenses down the line.

Why is Welded Wire Mesh Essential for Construction and Agriculture? - Selection Criteria for Quality Welded Wire Mesh Products

| Criteria | Description | Importance | Recommended Standards |

|---|---|---|---|

| Material Quality | The type of steel used in manufacturing the mesh. | Ensures durability and strength for structural integrity. | Mild steel or galvanized steel (ASTM A615). |

| Wire Gauge | Thickness of the wire used in the mesh. | Dictates the load-bearing capacity and applications. | Common gauges range from 8 to 18. |

| Mesh Size | Distance between the wires in the mesh. | Impacts functionality, especially in agricultural applications. | Common sizes include 1"x1", 2"x2". |

| Welding Technique | Method used to join wires together. | Affects strength and flexibility of the mesh. | Electro-galvanized or hot-dip galvanized welding. |

| Corrosion Resistance | Ability to withstand rust and environmental factors. | Increases longevity and reduces maintenance costs. | Galvanized coatings or PVC coatings. |

Related Posts

-

2026 Best Welded Wire Mesh Applications and Benefits Explained?

-

Top 10 Best Stainless Steel Wire Mesh Options for Your Projects?

-

Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

-

10 Essential Tips for Using a Wire Brush Effectively in Your Projects

-

Why You Should Choose Wire Cloth for Your Industrial Filter Needs

-

2025 Top 5 Stainless Steel Wire Rope Trends You Need to Know