Top Wire Brush Types to Choose for Effective Cleaning in 2025

In the realm of maintenance and cleaning tools, wire brushes play an indispensable role in various industries, including manufacturing, automotive, and metalworking. According to a recent market analysis report by Research and Markets, the global wire brush market is projected to grow significantly, reaching an estimated value of USD 1.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.5%. This growth is largely driven by the increasing demand for effective cleaning solutions that ensure the longevity and performance of equipment.

The versatility of wire brushes extends across multiple applications, from heavy-duty surface preparation to delicate finishing tasks. As workplace standards evolve and the pursuit of efficiency intensifies, selecting the appropriate wire brush type becomes crucial. Professionals must consider not only the material and construction of the brush but also the specific requirements of their cleaning task to optimize results. With advancements in technology and a better understanding of materials science, several wire brush types—each designed for varying levels of abrasion and durability—are set to gain prominence in 2025 and beyond, empowering users to achieve superior cleaning outcomes.

Overview of Wire Brush Types and Their Uses

Wire brushes are indispensable tools in various industries, offering a versatile means for cleaning and surface preparation. They come in multiple types, each designed for specific applications. The most common wire brush types include cup brushes, end brushes, and hand-held wire brushes. According to the Market Research Future report, the global market for industrial cleaning tools, including wire brushes, is projected to grow at a CAGR of 6.5% from 2021 to 2027, signaling a strong demand for effective cleaning solutions.

Cup brushes are particularly beneficial for larger surfaces, making them ideal for removing rust, paint, and scale from flat areas. Their design allows for flexibility in applications ranging from metalworking to masonry. End brushes, on the other hand, excel in reaching tight spaces and intricate shapes, making them a preferred choice for automotive and machinery cleaning. Recent data from the Industrial Products Manufacturers Association highlights that 45% of professionals prefer using end brushes for their ability to deliver precision cleaning without damaging delicate components.

Hand-held wire brushes remain an essential choice for manual cleaning tasks, proving useful in both professional workshop settings and DIY projects. They are favored for their ease of use and effectiveness in removing debris from hard-to-reach areas. The versatility and effectiveness of these wire brush types underscore their importance in maintaining equipment and ensuring safety across various industries, contributing to the growing market demand as outlined in the latest industry publications.

Top Wire Brush Types to Choose for Effective Cleaning in 2025

| Wire Brush Type | Best For | Material | Handle Type | Usage Frequency |

|---|---|---|---|---|

| Cup Brush | Removing Rust from Curved Surfaces | Steel | Crimped Plastic Handle | Frequent |

| Wire Wheel | Cleaning Flat Surfaces | Carbon Steel | Heavy-Duty Grip | Moderate |

| Hand Brush | Detailing and Precision Cleaning | Brass or Stainless Steel | Ergonomic Handle | Occasional |

| Strip-Style Brush | Removing Old Paint or Coating | Steel or Nylon | Standard Grip | Infrequent |

| Power Brushes | Heavy-Duty Cleaning Tasks | Steel | Compatible with Power Tools | Very Frequent |

Key Features to Consider When Choosing a Wire Brush

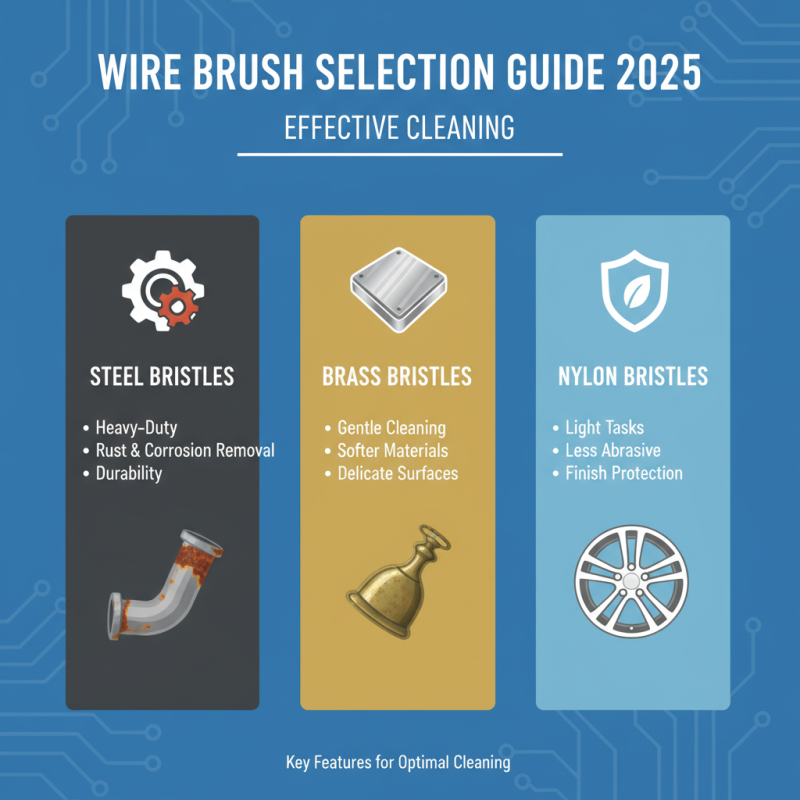

When selecting a wire brush for effective cleaning in 2025, several key features should be at the forefront of your decision-making process. Firstly, the type of bristles is crucial. Different wire materials, such as steel, brass, or nylon, offer varying degrees of abrasiveness and durability. Steel bristles are ideal for heavy-duty applications, such as removing rust and corrosion, while brass bristles are gentler and suited for softer materials or delicate surfaces. Additionally, nylon-bristle brushes are excellent for lighter cleaning tasks and are less aggressive, making them a good choice for protecting finishes.

Another important feature to consider is the brush shape and size. Wire brushes come in various forms, including hand-held, power tool attachments, and dedicated cleaning tools for specific tasks. A larger brush may cover more area efficiently, but a smaller brush provides better control for intricate work. Additionally, ergonomic designs can enhance comfort during prolonged use, allowing for a more effective cleaning process without causing strain on the hands. Finally, the brush's density, or the spacing between bristles, can significantly impact its cleaning ability; denser brushes are generally more effective for tougher jobs, while those with sparser bristles work well for finer cleaning tasks.

Popular Wire Brush Materials and Their Applications

When selecting the right wire brush for your cleaning tasks, understanding the materials and their various applications becomes essential. In 2025, we see an increasing preference for wire brushes made of stainless steel, brass, and nylon due to their unique properties that cater to different cleaning needs. For instance, stainless steel wire brushes are renowned for their durability and effectiveness in removing rust and paint, making them ideal for heavy-duty applications in industrial settings. According to a recent industry report, the demand for stainless steel wire brushes is expected to grow by 15% annually as industries focus on maintaining equipment and reducing wear and tear.

Brass wire brushes, on the other hand, offer a gentler approach, making them suitable for softer metals and delicate surfaces. Their anti-corrosive properties are excellent for use in automotive and electrical applications, where protecting the underlying material is crucial. Meanwhile, nylon wire brushes provide a safe alternative for cleaning without scratching or damaging surfaces, which is increasingly important in home and delicate craft applications. The versatility of these materials highlights the importance of choosing the right brush to match the cleaning task.

**Tips:** When selecting a wire brush, always consider the material and the surface you’ll be cleaning. For tough metal surfaces, stainless steel brushes will deliver the best results, while brass brushes can safeguard softer materials. Additionally, using the correct brush size allows for more effective cleaning without excessive wear on both the brush and the surface.

Top Wire Brush Types to Choose for Effective Cleaning in 2025

Maintenance Tips for Prolonging Wire Brush Lifespan

When it comes to utilizing wire brushes for effective cleaning, it’s crucial to maintain them properly to ensure their longevity and efficiency. Regular upkeep not only extends the lifespan of your wire brushes but also enhances their cleaning performance. One of the simplest yet most effective maintenance tips is to clean the bristles after each use. Removing debris and buildup helps prevent corrosion and damage, ensuring that the bristles remain effective for future tasks.

Another valuable tip is to store your wire brushes in a dry, cool place. Exposure to moisture can lead to rust and deterioration, significantly impacting their effectiveness. Additionally, consider using a protective cover or case to shield the brushes from dust and environmental factors that can cause wear over time. By following these practices, you can enjoy optimal performance from your wire brushes and minimize the frequency of replacements.

Lastly, inspect your wire brushes regularly. Look for signs of wear such as frayed bristles or bent wires. Addressing these issues promptly can prevent further deterioration, allowing you to make necessary repairs or replacements before the brush becomes inefficient. By incorporating these maintenance strategies, you can maximize the value and functionality of your wire brushes well into 2025 and beyond.

Future Trends in Wire Brush Design and Technology

As we look towards 2025, the future of wire brush design and technology is set to undergo significant evolution, driven by advancements in materials and user feedback. The integration of lightweight, durable composites promises to revolutionize the wire brush industry, offering enhanced performance without compromising on strength. Furthermore, innovations in bristle technology, such as the development of corrosion-resistant materials, will ensure longer-lasting brushes capable of maintaining their effectiveness in various environments. This shift toward durable materials not only extends the lifespan of the brushes but also enhances their cleaning capabilities across diverse applications.

In addition to material advancements, the design of wire brushes is expected to become more ergonomic and user-centric. Research into hand ergonomics will lead to the creation of handles that provide a better grip and reduce fatigue during extended use. Moreover, the incorporation of smart technologies, such as sensors that monitor bristle wear or efficiency levels, could inform users when it's time for a replacement, promoting optimal cleaning performance.

The future of wire brushes looks promising as these trends combine to create tools that not only meet the demands of modern cleaning tasks but also prioritize user experience and environmental sustainability.

Related Posts

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

10 Best Stainless Steel Mesh Options for Versatile Applications

-

Understanding the Essential Role of Steel Rope in Everyday Applications

-

What is a Stainless Steel Supplier and How to Choose the Right One

-

Discover the Best Wire Brush Drill Attachments of 2025 for Efficient Cleaning and Rust Removal

-

The Versatility of Stainless Steel Cable: Applications, Benefits, and Innovations